A steam boiler is essentially a closed vessel. Its core task is to use the heat generated by the combustion of fuel, water into steam. This process may seem simple, but it contains complex physical and chemical principles. Steam has a wide range of uses in industry and commerce, from common heating to large-scale power generation, all of which are dependent on the operation of a steam boiler.

The work of a steam boiler begins with the combustion of fuel in a combustion chamber. When the fuel is ignited, hot gases are produced. These hot gases carry a lot of heat energy, which is next exchanged with the water surrounding the combustion chamber. As the heat continues to be transferred, the water absorbs enough energy to gradually increase in temperature until it reaches the boiling point, where it begins to boil and convert to steam. This process continues week after week, continuously providing steam for each application.

This classification directly impacts a boiler's fuel utilization efficiency and combustion stability. Its core focus is on the differences in the fuel's combustion pattern within the furnace.

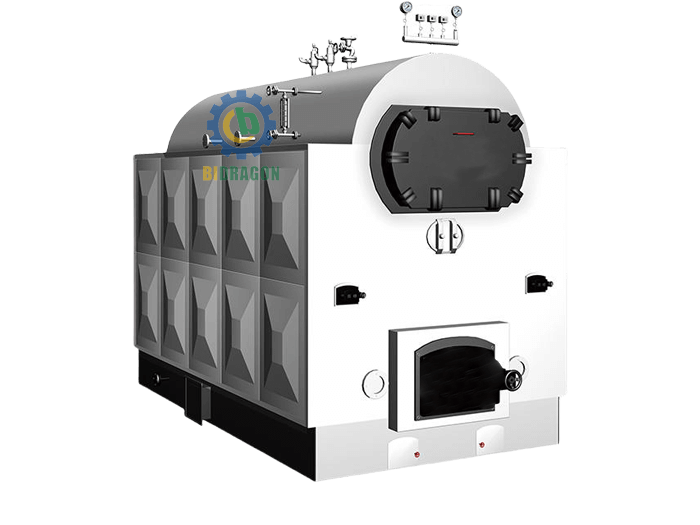

Layer-fired furnaces: Fuel is burned in layers on a grate. Solid fuels such as coal and biomass pellets are evenly spread across a movable or fixed grate, with air passing through the fuel layer from beneath the grate to assist combustion. This type of boiler has a relatively simple structure and is easy to operate and maintain. It is suitable for burning solid fuels in the form of blocks or pellets and is commonly used in small and medium-sized industrial applications, such as heating and local steam use in small factories.

Chamber-fired furnaces: Fuel is burned in a suspended, atomized, powdered, or gaseous form within the furnace, without a fixed combustion layer. For example, oil-fired boilers atomize diesel and heavy oil and spray them into the furnace. Gas-fired boilers directly mix natural gas and other gases with air for ignition. Pulverized coal boilers blow pulverized coal into the furnace for combustion. This type of boiler offers fast combustion and high thermal efficiency, adapting to high steam loads. It is widely used in large factories, power plants, and other applications. Fluidized bed furnaces (fluidized bed furnaces): Fuel particles are "blown" within the furnace by high-speed airflow, creating a suspended combustion state similar to "boiling," creating a large fuel-air contact area. Their advantages include the ability to burn low-grade fuels such as inferior coal and gangue, and easier removal of pollutants (such as sulfides). These furnaces are suitable for industrial sectors requiring high fuel compatibility and environmental protection, such as auxiliary steam in the chemical and metallurgical industries.

Pressure is a core safety and performance indicator for steam boilers, directly determining steam temperature, enthalpy, and applicable processes. They are categorized into low-pressure, medium-pressure, high-pressure, and ultra-high-pressure levels.

Low-pressure boilers: Rated operating pressure ≤ 2.5 MPa, corresponding to a saturated steam temperature typically not exceeding 223°C. They are primarily used in low-parameter steam applications, such as fabric drying in textile mills, steaming and processing in food factories, and small heating systems. They have lower steam pressure and temperature requirements, and are relatively easy to manage and control.

Medium-pressure boilers: Rated operating pressures range from 3.9 to 5.2 MPa, with saturated steam temperatures of approximately 242 to 264°C. Some medium-pressure boilers can also generate superheated steam (temperatures reaching approximately 400°C). These boilers are commonly used in medium-sized industrial production, such as parts heat treatment in machinery manufacturing and heating small and medium-sized reactors in the chemical industry. They can meet the medium-sized steam needs of most industrial processes.

High-pressure boilers: Rated operating pressures range from 9.8 to 13.7 MPa, with superheated steam temperatures typically ranging from 450 to 540°C. They primarily provide steam for high-performance processes or power generation, such as synthesis reactions in large chemical plants and steam turbine drive systems in small and medium-sized thermal power plants. These boilers place significantly higher demands on equipment materials and safety controls.

Ultra-high-pressure and above boilers: Rated operating pressures ≥16.7 MPa, with superheated steam temperatures reaching 540 to 600°C or even higher, are used only in large thermal power plants or extra-large industrial facilities (such as cracking units in large petrochemical refineries). They are high-end, heavy-duty equipment with extremely complex technology and high manufacturing costs.

Fuel is the core energy source for boiler operation. Different fuels require different combustion systems, exhaust gas treatment methods, and operating costs.

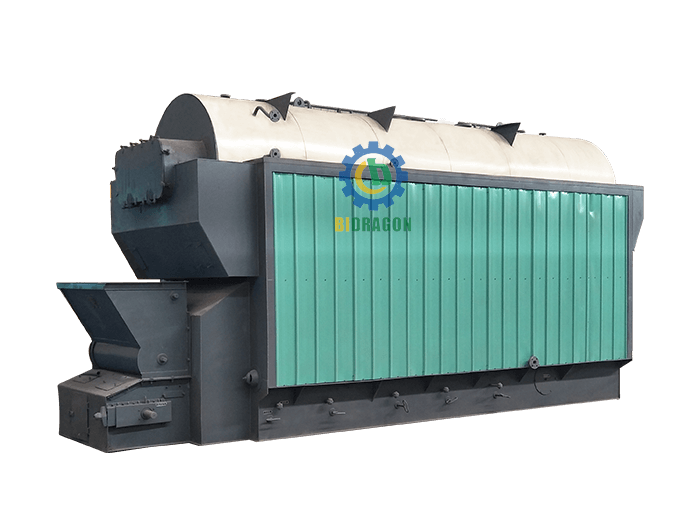

Coal-fired boilers: These primarily use coal (bituminous coal, anthracite, lignite, etc.). These were once the mainstream boiler type in the industrial sector, offering low fuel costs but requiring complex dust removal, desulfurization, and denitrification equipment to meet environmental protection requirements. Currently, in regions with strict environmental protection policies, small and medium-sized coal-fired boilers are gradually being replaced. Only large, high-efficiency coal-fired boilers (such as circulating fluidized bed boilers) are still used in specific scenarios (e.g., large power plants and coal chemical plants).

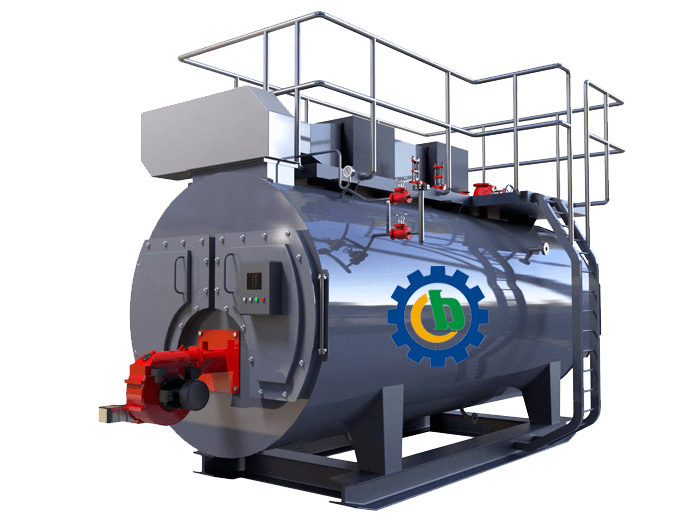

Oil-fired boilers: These use liquid fuels (diesel, heavy oil, residual oil, etc.). They offer high combustion efficiency, flexible start-up and shutdown, and low exhaust pollutants (such as dust). However, their fuel costs are significantly higher than coal. They are primarily used in scenarios with strict environmental requirements, large fluctuations in steam demand, and the absence of natural gas supply (e.g., small factories and temporary steam installations). Gas-fired boilers: These use gaseous fuels (natural gas, liquefied petroleum gas, coalbed methane, etc.) and offer clean combustion (almost no dust emissions, low nitrogen oxide emissions), high thermal efficiency (typically exceeding 90%), and a high degree of automation. Current environmental protection policies encourage their promotion and widespread use in urban areas, the food and pharmaceutical industries (which require high steam cleanliness), and other locations. However, they rely on a stable gas supply network.

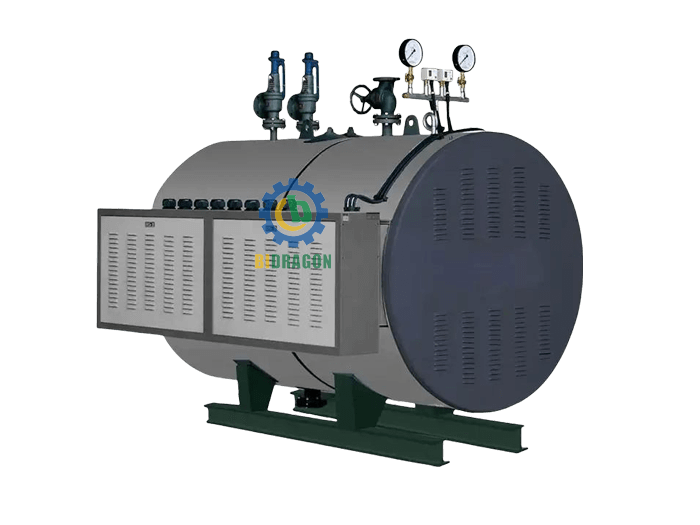

Biomass boilers: These use biomass fuels (straw pellets, wood pellets, rice husks, etc.) as renewable energy and offer good environmental performance (combustion products can be recycled). However, the fuel has a low calorific value and is prone to coking, requiring tailored furnace and decoking systems. They are suitable for small and medium-sized factories in areas with abundant biomass resources (such as agricultural production areas and forestry processing zones). Electric Steam Boilers: Powered by electricity, they heat water into steam through electric heating tubes. They are completely emission-free, quiet, compact, and quick to start and stop. However, they have extremely high operating costs and are only used in specialized applications with stringent environmental requirements (such as pharmaceutical GMP workshops and electronics cleanrooms), low steam consumption, and the lack of other clean energy sources.

The structural type determines the boiler's heat exchange efficiency, floor space, and installation method. The core difference lies in the layout of the "boiler" (steam-water system) and the "furnace" (combustion system).

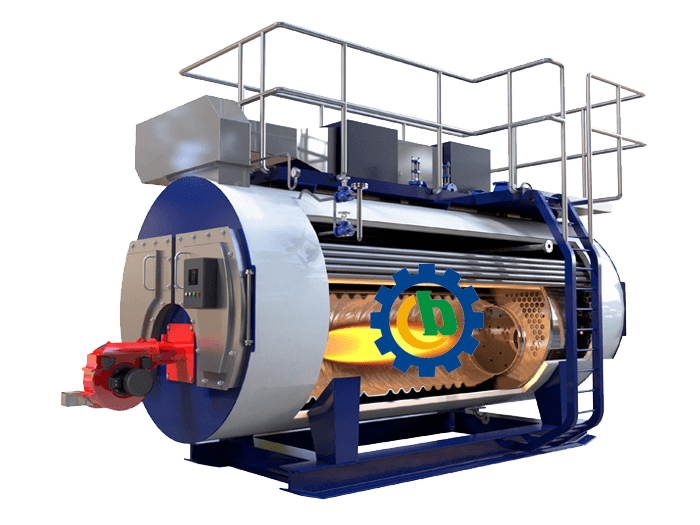

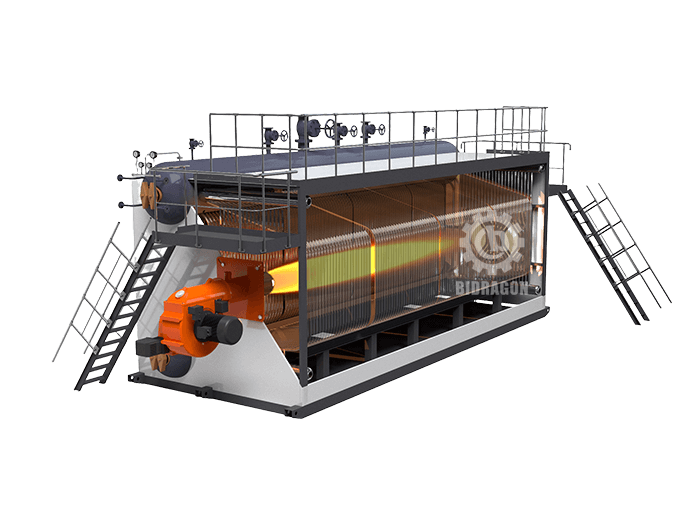

Fire Tube Boilers (Shell and Tube Boilers): High-temperature flue gas flows within the "fire tubes," while water is heated within the shell outside the tubes. They have a simple structure, low manufacturing complexity, and low pressure ratings (typically ≤2.5 MPa). They are suitable for small and medium-sized steam users (such as small factories and the catering industry). However, they have lower heat exchange efficiency (typically ≤85%) and are larger in size. Common "vertical fire tube boilers" and "horizontal internal combustion fire tube boilers" fall into this category. Water-tube boilers: Water flows within the tubes, while high-temperature flue gas scours and exchanges heat outside them. This results in a large heat exchange area, high thermal efficiency (typically ≥85%), and high pressure ratings (capable of reaching high pressures and above). These are currently the mainstream structural form for medium- and large-scale industrial steam boilers. Depending on the tube layout, they can be categorized as horizontal water-tube boilers, vertical water-tube boilers, and once-through boilers (without a steam drum, where water passes through the tubes once to heat steam, suitable for high pressures and above). They are widely used in large factories, power plants, and other applications.

Water-tube and fire-tube combination boilers: Combining the structural features of fire-tube and water-tube boilers, they typically use fire tubes as the primary heat exchange component, supplemented by water tubes to enhance heat transfer. They balance structural simplicity with high thermal efficiency, offering a pressure rating somewhere in between. They are suitable for medium-sized steam users (such as medium-sized textile mills and machinery plants) and are a transitional structural form.

The evaporation capacity directly reflects the boiler's steam supply capacity and determines the scale of industrial production for which it is suitable.

Small boilers: Rated evaporation capacity ≤ 20 t/h, corresponding to low or medium pressure parameters, primarily provide steam for small and medium-sized factories, such as small food plants (evaporation capacity 2-4 t/h) and small chemical plants (evaporation capacity 10-20 t/h). These boilers require a small footprint, low investment costs, and require a smaller operation and maintenance team.

Medium boilers: Rated evaporation capacity 20-100 t/h, mostly medium or high pressure parameters, are used for medium-sized industrial enterprises or regional centralized steam supply, such as medium-sized refineries (evaporation capacity 35-75 t/h) and large textile parks (evaporation capacity 50-100 t/h). They require comprehensive auxiliary systems (such as water treatment and deaeration systems). Large boilers: Rated evaporation capacity ≥ 100t/h, almost all of which are high pressure or above parameters. They are only used in large thermal power stations (such as a 300MW unit with a boiler evaporation capacity of about 1000t/h) or extra-large industrial plants. The equipment is large in size and the system is complex, requiring a professional team for operation, management and maintenance.

Manufacturing is one of the largest applications for industrial steam boilers, with steam providing stable thermal energy for various key production processes.

Metalworking: During the forging, casting, and heat treatment processes of metals like steel and aluminum, high-temperature steam from steam boilers is used to heat metal workpieces. Heating metal makes it easier to shape and also changes its internal structure, increasing its hardness, toughness, and corrosion resistance. This is crucial for producing high-quality automotive parts, mechanical components, and construction steel.

Chemical Production: Numerous chemical reactions, such as polymerization, distillation, and esterification, require precise and continuous temperature control. Steam generated by industrial steam boilers, acting as a heat source, maintains the desired reaction temperature within reactors or distillation columns, ensuring the stable quality of chemical products such as fertilizers, plastics, and dyes, and preventing the generation of hazardous byproducts due to temperature fluctuations.

Food and Beverage Processing: Clean, high-temperature steam provided by steam boilers is used for food sterilization, cooking, and drying. For example, in canning, high-temperature steam sterilization can extend the shelf life of food. During baking, steam can regulate the humidity and temperature in the oven, improving the texture of bread and pastries. In beverage processing, steam heats ingredients for extraction (such as tea and fruit juice) while avoiding direct contact with food, ensuring hygiene.

Steam boilers play an irreplaceable role in energy conversion and power supply, particularly in the integration of traditional power generation and renewable energy.

Thermal Power Generation: In power plants powered by fossil fuels such as coal, natural gas, and oil, industrial steam boilers heat water to produce superheated steam. This high-pressure steam drives turbine generators, converting heat energy into electricity and transmitting it to the grid to meet the electricity needs of industry, cities, and households.

Biomass Energy Utilization: With the development of renewable energy, steam boilers are widely used in biomass power plants. They burn biomass fuels such as wood chips, straw, and agricultural and forestry waste to generate steam for power generation or cogeneration, reducing dependence on fossil fuels while promoting the recycling of agricultural and forestry waste. Waste Heat Recovery for Power Generation: Industries like steel and cement emit high-temperature exhaust gases during production. Industrial steam boilers can recover this waste heat to heat water and generate steam, which drives small steam turbines to provide auxiliary power for on-site production, reducing energy waste and lowering operating costs.

Industrial steam boilers are core equipment for heating commercial buildings, industrial parks, and residential areas, and are particularly in high demand in cold climates.

Industrial Central Heating: In industrial parks with multiple factories, large industrial steam boilers deliver high-temperature steam to each factory via pipelines. Heat exchangers in these factories convert the steam's heat energy into hot water or hot air, which heats production workshops, maintaining stable equipment operation and a comfortable working environment for employees.

Commercial and Public Building HVAC: The HVAC systems of large commercial complexes, hospitals, and schools rely on steam boilers. The steam heats water in the heat exchanger, which circulates through radiators or air conditioning units to provide indoor heating. In summer, the steam can also drive absorption chillers to produce chilled water for air conditioning, achieving dual heating and cooling. Greenhouse Heating: In agricultural greenhouses where vegetables, flowers, and seedlings are grown, a constant temperature is crucial for crop growth. Small and medium-sized industrial steam boilers deliver low-pressure steam to greenhouse heating pipes, ensuring that indoor temperatures remain within the optimal range for crop growth during cold seasons, extending the growing cycle and increasing yields.

The pharmaceutical and medical industries have extremely high requirements for sterile environments and temperature accuracy, and industrial steam boilers provide critical support for meeting these standards.

Pharmaceutical Sterilization: In pharmaceutical production, equipment such as reactors, pipelines, and filling machines, as well as raw materials such as pharmaceutical powders and injections, require rigorous sterilization to prevent microbial contamination. Industrial steam boilers generate high-purity saturated steam that meets pharmaceutical-grade standards. Through moist heat sterilization, they effectively kill bacteria, viruses, and spores while ensuring the efficacy of the drugs.

Hospital Sterilization and Heating: Hospitals require large quantities of sterile steam for sterilizing medical devices such as surgical blades and syringes in autoclaves. Steam boilers also power hospital heating systems, maintaining a warm environment in wards, operating rooms, and laboratories. Steam heat exchangers also provide a stable supply of hot water for daily patient care, cleaning, and other needs.

The raw material processing and drying stages of the textile and papermaking industries are highly dependent on steam, and steam boilers directly impact product quality and production efficiency.

Textile Processing: Steam is required for multiple stages of textile production. For example, during cotton spinning, steam humidifies the workshop to prevent cotton fibers from drying out and breaking. During the printing, dyeing, and finishing process, steam heats the dye bath to ensure even dye adhesion to the fabric and improve color fastness. After dyeing, steam-driven dryers rapidly dry the fabric, shortening production cycles.

Papermaking: Pulp cooking and paper drying are key processes in paper mills, both requiring steam. During pulp cooking, the high-temperature steam generated by industrial steam boilers heats the cooking tanks, breaking down wood or plant fibers into pulp. In the drying section of the paper machine, multiple sets of steam-heated drying cylinders use steam heat energy to evaporate moisture from the wet paper sheets, forming dry paper rolls that meet thickness and moisture content requirements.

The capacity and pressure of a factory's steam boilers must be precisely matched to actual production needs to avoid energy waste or production interruptions. This must be scientifically determined through three core steps: demand data collection, load calculation, and pressure matching. The specific steps are as follows:

Before determining boiler parameters, it's necessary to first analyze the demand characteristics of all steam users in the factory and clarify the three key pieces of information: steam usage, purpose, and pressure requirements. This will provide a basis for subsequent calculations.

Compile a list of all steam-consuming equipment: List all steam-consuming equipment in the factory, including production process equipment (such as heat exchangers, reactors, and dryers), auxiliary facilities (such as heating heaters and hot water generators), and backup needs (such as temporary alternative steam sources during equipment maintenance). This ensures that no potential steam consumption points are missed. Record the steam parameters of each piece of equipment: For each steam device, clearly specify its rated steam consumption (usually in kilograms per hour (kg/h) or tons per hour (t/h), which can be obtained from the equipment manual), required steam pressure (i.e., the steam pressure required for normal operation of the equipment, such as 0.8 MPa or 1.2 MPa. Note the distinction between "gauge pressure" and "absolute pressure"; gauge pressure is often used in industrial scenarios), and operating hours (e.g., whether it operates continuously 24 hours a day, only during production shifts, and seasonal start-up and shutdown conditions, such as for dedicated winter heating equipment).

Mark special demand scenarios: Record fluctuating steam demand characteristics, such as the instantaneous maximum steam usage during peak production periods (e.g., peak steam consumption at the start of a production line), pulsed demand from intermittent production equipment (e.g., a sudden increase in steam usage during each batch reactor feed), and pressure fluctuations during process adjustments (e.g., certain equipment requires switching to different steam pressures during different production phases). This information will directly impact the boiler's "capacity redundancy" and "pressure regulation capability."

Boiler capacity refers to the amount of steam produced per unit time (usually measured in tons per hour (t/h), also known as "evaporation capacity"). It must be determined based on actual steam consumption and combined with load stacking, redundancy factors, and heat loss compensation to ensure coverage under all operating conditions:

Calculate total steam consumption (base load): Add the rated steam consumption of all steam equipment × the operating factor to determine the plant's total continuous steam consumption. The operating factor refers to the ratio of the equipment's actual operating time to a full 24-hour day. For example, if a reactor operates only 8 hours per day, its operating factor is 8/24, which equals 0.33. If multiple equipment operate at different times (such as production lines operating in shifts), the maximum simultaneous operating load should be used for calculations, rather than simply adding the rated consumption of all equipment (to avoid overestimating base load).

Account for load fluctuations and redundancy: The plant's steam demand is not constant, so reserve capacity for peak loads and emergencies. Typically, the margin is calculated as "base load x 10%-20%." The specific ratio should be adjusted based on the degree of production fluctuation. For stable production processes and regular equipment operation (such as continuous chemical production lines), a 10% margin is sufficient. For high-steam-consuming equipment with frequent starts and stops (such as intermittent drying equipment) or future expansion plans, the margin should be increased to 15%-20% to prevent the boiler from being unable to meet instantaneous peak demand when operating at full capacity.

Compensate for heat losses during steam transmission and use: When steam is transported from the boiler outlet through pipelines to end equipment, it loses heat and condensation (often referred to as "steam loss"), which should be factored into the boiler capacity. The loss ratio is related to pipeline length and insulation quality: For short-distance transmission (e.g., pipeline length <100 meters with good insulation), the loss is approximately 5%-8%; for long-distance transmission (e.g., pipeline length >300 meters with poor insulation), the loss can reach 10%-15%. The final boiler capacity = (base load + margin) ÷ (1 - steam loss ratio) to ensure sufficient steam for end equipment.

Boiler pressure must meet both the "maximum pressure requirement" of the terminal equipment and the "steam transmission pressure loss" to avoid energy waste due to excessive pressure or production impacts due to insufficient pressure. The specific method for determining this is as follows:

Determine the maximum pressure requirement of the terminal equipment: Review the rated steam pressures of all steam equipment and use the highest value as the base pressure. For example, if a factory reactor requires 1.0 MPa steam, a dryer requires 0.8 MPa steam, and a heating system requires 0.4 MPa steam, then the base pressure is 1.0 MPa. If the boiler pressure is lower than 1.0 MPa, the reactor will not function properly, and even if other equipment has sufficient pressure, production will be interrupted.

Compensate for pressure loss during steam transmission: As steam flows through pipelines, pressure loss occurs due to pipe friction, valve throttling, and elbow resistance. This loss must be added to the base pressure to ensure that the inlet pressure of the terminal equipment meets the required pressure. Pressure loss calculations require consideration of pipeline parameters: the smaller the pipe diameter, the longer the pipe length, and the more valves/elbows, the greater the pressure loss. Typically, the pressure loss is approximately 0.05-0.1 MPa per 100 meters of pipeline. For example, if the pipeline from the boiler to the reactor is 200 meters long and the pressure loss is approximately 0.1-0.2 MPa, the boiler design pressure must be ≥1.0 MPa (equipment requirements) + 0.1-0.2 MPa (pressure loss) = 1.1-1.2 MPa.

Combining pressure regulation with a safety margin: Considering the need for stable pressure regulation during boiler operation (for example, some equipment requires pressure reduction via a pressure reducing valve) and the need to meet safety regulations, an additional safety margin of 0.1-0.3 MPa should be reserved. For example, in the above scenario, if the pressure loss is calculated as 0.2 MPa, the base pressure is 1.0 MPa. After adding a 0.2 MPa safety margin, the boiler design pressure can be determined as 1.4 MPa. This ensures sufficient pressure at the terminal equipment, provides a buffer for pressure regulation, and meets the pressure reserve requirements for safe boiler operation.

Capacity Allocation for Multiple Boilers Operating in Parallel: If the factory's total steam demand is large or the load fluctuates frequently (e.g., high load during the day and low load at night), multiple boilers can be operated in parallel. In this case, the capacity of each boiler should be determined by "maximum simultaneous load ÷ number of boilers + single-unit redundancy." For example, if the total demand is 10 t/h and two boilers are planned, the capacity of each boiler can be set at 6 t/h (10 ÷ 2 + 10% redundancy). This prevents a complete shutdown due to a single boiler failure and reduces energy consumption by matching load fluctuations by starting and stopping some boilers.

The indirect impact of steam quality on pressure: Some production processes require steam "dryness" (i.e., the water content in the steam) (for example, high-precision drying processes require saturated steam with a dryness of ≥95%). If the boiler pressure is too low, the temperature and dryness of the saturated steam are susceptible to fluctuations (the lower the pressure, the lower the saturation temperature, and the more likely water in the steam will condense). In this case, the boiler design pressure should be appropriately increased. By leveraging the characteristics of saturated steam at higher pressures, the steam dryness can be guaranteed, indirectly meeting the steam quality requirements of the process.

Reaching capacity for future expansion: If a factory has a clear expansion plan (such as adding a new production line within 1-2 years), it should reserve an additional capacity and pressure margin of "increased consumption due to expansion × 100%" based on current steam demand (to avoid short-term boiler replacement). For example, if the current total demand is 5 t/h and the planned expansion adds 3 t/h, the boiler capacity should be calculated as 8 t/h (5 + 3), and the pressure should be re-evaluated based on the pressure requirements of the new equipment to ensure that the boiler itself does not require modification after the expansion.

Steam boilers are core thermal energy equipment for industrial production, commercial heating, and other applications. Their efficiency directly impacts energy consumption costs and production stability. Improving steam boiler efficiency requires multiple approaches, including equipment optimization, operational management, and technological upgrades. The following are specific and practical methods, covering key efficiency improvements throughout the steam boiler's lifecycle:

Combustion efficiency is a key factor in determining a steam boiler's overall efficiency. This ensures that fuel and air are thoroughly mixed and completely burned, avoiding unburned fuel loss and harmful gas emissions.

Precisely Control the Air-Fuel Ratio: Based on the fuel type used in the steam boiler (e.g., natural gas, diesel, biomass, etc.), professional instruments (such as flue gas analyzers) monitor flue gas composition in real time and adjust the air supply accordingly. For example, excessive air during natural gas combustion will cause the flue gas to carry away excessive heat; insufficient air will result in incomplete combustion, resulting in the formation of soot that adheres to the boiler's heating surfaces. Both factors reduce efficiency. Ideally, the oxygen content in the flue gas should be controlled within a reasonable range (typically 2%-6%, depending on the fuel characteristics) to ensure complete combustion and minimize heat loss. Upgrading burner equipment: Older burners are prone to poor atomization and uneven flame distribution, resulting in uneven heating across the steam boiler's heating surface and localized heat loss. Replacing with high-efficiency, low-NOx burners not only improves fuel atomization quality, resulting in a more concentrated flame and more uniform temperature distribution, but also reduces nitrogen oxide emissions and exhaust gas temperatures, further minimizing heat loss. Some advanced burners also feature automatic adjustment, allowing them to adjust fuel supply and air volume in real time based on boiler load changes, adapting to combustion requirements under varying operating conditions.

Regularly clean the combustion system of carbon deposits and impurities: After long-term operation, the burner nozzles and furnace walls of steam boilers can easily accumulate carbon deposits, dust, and other impurities, hindering heat transfer and affecting fuel atomization. According to the equipment maintenance cycle, disassemble the burner to clean the nozzles and clean the furnace walls with high-pressure air or a specialized cleaning agent to ensure the combustion system is free of blockage and fouling, maintaining efficient combustion.

The heating surfaces of a steam boiler (such as the furnace water-cooled walls, convection tube bundles, economizers, and air preheaters) are the key carriers of heat transfer from combustion products to water/steam. Scaling and corrosion on these surfaces significantly reduce heat transfer efficiency and increase energy consumption.

Regularly descale to prevent scaling on heating surfaces: Calcium and magnesium ions in water form scale at high temperatures, adhering to the heating surfaces of steam boilers. Scale has a thermal conductivity that is only 1/10-1/50 that of metal. This increases the thermal resistance of the heating surfaces, preventing effective heat transfer to the water. This not only reduces steam production efficiency but can also cause deformation and cracking of the heating surfaces due to localized overheating, leading to safety hazards such as deformation and cracking. Based on the water quality, an appropriate water treatment solution (such as ion exchange or reverse osmosis) should be selected to reduce the hardness of the incoming water. At the same time, chemical descaling (e.g., using an acidic descaling agent, but strictly controlling the concentration and operating procedures to avoid metal corrosion) or physical descaling (e.g., high-pressure water jet cleaning) should be regularly used to remove scale from the heating surfaces and ensure their cleanliness.

Preventing Heating Surface Corrosion and Extending Equipment Life: During steam boiler operation, acidic substances in flue gas (such as sulfur dioxide and nitrogen oxides) or oxygen in water can cause corrosion of the heating surfaces, forming corrosion products that adhere to the surface and also affect heat transfer. Corrosion of the feedwater system and heating surfaces should be prevented by controlling the pH value of the boiler feedwater (typically maintained between 8.5 and 10.5) and adding corrosion inhibitors (such as phosphates and amine compounds). Regular inspections of the heating surfaces should also be conducted, and localized corrosion spots should be promptly addressed to prevent further corrosion and maintain the thermal conductivity and structural integrity of the heating surfaces.

Inspect and repair heating surface leaks and sealing issues: Leaks in the steam boiler's heating surface (such as cracks in the water-wall tubes or loose convection tube bundle connections) can cause water or steam leaks, wasting energy and potentially affecting boiler pressure stability. Regular hydrostatic tests are required to verify the sealing of the heating surface. Also, inspect the seals in the boiler furnace and flue (such as asbestos gaskets and sealants) and replace any aging or damaged components to prevent cold air from entering the furnace or high-temperature flue gas from leaking out of the flue, thereby minimizing heat loss.

Steam loss during transportation and use can indirectly reduce the overall efficiency of the boiler. Scientific operation and management are essential to reduce steam waste and improve steam utilization.

Rationally control steam boiler load to avoid underload or overload operation: Steam boilers operate most efficiently at their designed load. Underload operation (e.g., actual steam consumption is less than 50% of the designed load) results in lower furnace temperatures, reduced combustion efficiency, and increased heat loss from exhaust gas. Overload operation prevents the boiler's heating surfaces from fully absorbing heat, causing a sharp rise in exhaust gas temperature and potentially degrading steam quality (e.g., water carryover). Based on actual steam demand, the number of operating boilers and the load of each boiler should be adjusted appropriately, aiming to maintain each boiler within the 70%-100% designed load range. Avoid frequent starts and stops or prolonged low-load operation.

Recycle steam condensate to reduce feedwater heating energy consumption: After steam releases heat in equipment (such as heat exchangers and steam irons), it condenses into high-temperature condensate (typically 80-100°C). Directly discharging this condensate wastes significant amounts of heat energy and water resources. Install a condensate recovery system to collect the condensate and return it to the steam boiler feedwater system, replacing some of the normal-temperature tap water. High-temperature condensate not only reduces the fuel consumption required to heat boiler feedwater (for example, heating 10°C tap water to 100°C consumes a certain amount of heat, while using 90°C condensate saves approximately 80% of this heating energy), but also reduces boiler blowdown and water waste.

Strengthen steam pipeline insulation to reduce heat loss along the way: Poorly insulated pipelines during steam transmission from the boiler to steam-consuming equipment can cause the steam temperature to drop and even produce secondary condensate, which not only reduces steam quality but also wastes heat energy. Insulate steam pipelines with high-efficiency insulation materials (such as rock wool, glass wool, or polyurethane insulated pipes) to ensure that the outer surface temperature does not exceed the ambient temperature + 25°C (or meet relevant energy-saving standards). Regularly inspect the integrity of the insulation layer and repair any damaged or missing insulation to minimize heat loss during steam transmission.

Promptly repair steam system leaks to avoid steam waste: Leaks in steam pipelines, valves, and connections to steam-consuming equipment can lead to continuous steam loss. According to statistics, unrepaired leaks can cause 5%-15% steam loss. Regularly inspect steam system interfaces and valve seals using an ultrasonic leak detector or soapy water. If leaks are found, promptly replace seals or repair pipes to reduce steam waste.

The performance of a steam boiler's auxiliary equipment (such as economizers, air preheaters, and feedwater pumps) directly impacts the boiler's energy efficiency. Upgrading or optimizing these auxiliary equipment can further improve the boiler's overall efficiency.

Install or upgrade an economizer to utilize exhaust gas waste heat for feedwater heating: An economizer is a heat exchanger installed at the end of a steam boiler's flue. It utilizes waste heat from the boiler's exhaust gas (typically at a temperature of 150-250°C) to heat the boiler's feedwater. Without an economizer, heat from the exhaust gas is directly released into the atmosphere, wasting energy. Installing an economizer can raise the feedwater temperature by 30-80°C, reducing the fuel consumption required to heat the feedwater in the boiler furnace and typically increasing steam boiler efficiency by 5%-10%. For boilers already equipped with economizers, if the economizer's heat transfer efficiency decreases (e.g., due to scaling inside the tubes or ash accumulation outside the tubes), it should be cleaned regularly or upgraded to a high-efficiency threaded tube economizer or finned tube economizer to increase the heat transfer area and efficiency.

Install an air preheater to utilize exhaust gas waste heat to heat the combustion air: Similar to an economizer, an air preheater is also installed at the end of the flue and uses exhaust gas waste heat to heat the air entering the burner. This heated air (typically by 50-150°C) enters the furnace, raising the furnace temperature and promoting more complete fuel combustion. It also reduces the heat consumption required for fuel combustion (no fuel is required to heat the cold air), further lowering the exhaust gas temperature. Using an air preheater in conjunction with an economizer can reduce the exhaust temperature of a steam boiler to below 100°C, significantly reducing exhaust heat loss and increasing boiler efficiency by an additional 3%-8%.

Optimize feedwater pump operation to reduce electricity consumption: A steam boiler's feedwater pump continuously delivers feedwater to the boiler, and its electricity consumption is one of the main energy consumers among the boiler's auxiliary equipment. Older feedwater pumps often operate at a fixed speed, regardless of the boiler's actual feedwater demand. This can lead to energy waste, often resulting in a "big horse pulling a small cart" effect. Fixed-speed feedwater pumps can be replaced with variable-speed feedwater pumps. These pump speeds can be adjusted in real time based on the boiler water level and feedwater demand, reducing power loss caused by idling or high-load operation. Regular maintenance of the feedwater pumps is also recommended, including cleaning impurities and lubricating bearings to ensure efficient operation.

For older, less efficient steam boilers, replacing traditional operating methods with technological upgrades can fundamentally improve efficiency while meeting environmental requirements.

Converting to a waste heat-utilizing steam boiler to recover industrial waste heat: If an enterprise has other high-temperature industrial waste heat (such as blast furnace gas from steel mills, process exhaust from chemical plants, and exhaust steam from power plants), traditional steam boilers can be converted to waste heat-utilizing boilers. This waste heat can be used to generate steam, replacing some or all of the heat generated by fuel combustion. This conversion not only significantly reduces fuel consumption (even achieving "zero-fuel" operation), but also reduces environmental pollution caused by direct discharge of industrial waste heat, typically reducing energy consumption by over 30%.

Introducing an intelligent control system to achieve automated and precise steam boiler operation: Traditional steam boilers rely on manual adjustments, which are prone to operational errors (such as improper air-fuel ratio control and untimely load adjustments), affecting efficiency. With the introduction of an intelligent control system, sensors can collect real-time steam boiler operating parameters (such as furnace temperature, exhaust gas temperature, steam pressure, water level, and flue gas composition). The control system automatically adjusts the burner's fuel supply, air volume, and feedwater flow rate based on pre-set algorithms, achieving precise air-fuel ratio control, automatic load matching, and automatic fault alarms. Intelligent control systems not only reduce manual errors but also optimize operating parameters through data analysis, keeping steam boilers operating at optimal efficiency over the long term. This typically improves efficiency by 2%-5%.

Replacing old, inefficient equipment with high-efficiency, energy-saving steam boilers: If a steam boiler has been in operation for over 15 years and, after multiple maintenance and retrofits, its efficiency remains below 75% (traditional coal-fired steam boilers typically have an efficiency of around 65%-75%, while high-efficiency gas-fired steam boilers can reach over 90%), it is recommended to directly replace it with a high-efficiency, energy-saving boiler. For example, a traditional chain grate coal-fired boiler could be replaced with a circulating fluidized bed coal-fired boiler, or with a high-efficiency condensing gas-fired steam boiler. Condensing gas-fired steam boilers utilize the latent heat released by condensing water vapor in the flue gas to further reduce exhaust gas temperatures (to as low as 50-60°C). Their thermal efficiency can reach over 95%, reducing fuel consumption by 10%-15% compared to traditional gas-fired boilers. They also emit lower nitrogen oxides, making them more environmentally friendly.

Daily Maintenance Considerations for Industrial Steam Boilers: Key Points for Ensuring Efficient and Safe Operation

As critical equipment providing stable steam in the production process, routine maintenance of industrial steam boilers directly impacts operational efficiency, service life, and operational safety. The following details key aspects of daily maintenance for industrial steam boilers, helping companies mitigate failure risks and ensure a continuous and stable steam supply.

Water level and water quality are the lifeline of industrial steam boilers. Abnormalities can cause serious problems such as dry-burning and scaling, directly impacting steam output quality and equipment safety.

Real-time water level monitoring to avoid abnormal fluctuations: Use a boiler-attached water level gauge (such as a glass tube water level gauge or electrode water level gauge) to check the water level at least once an hour to ensure it remains within the specified normal range (usually between 1/2 and 2/3 of the gauge). Strictly avoid "low" or "full" water levels. A low water level can cause the boiler's heating surfaces to dry out, leading to overheating, deformation, and even cracking of the tube walls. A full water level can cause water to enter the steam, reducing steam quality and potentially impacting the normal operation of subsequent steam-consuming equipment (such as heat exchangers and steam turbines). If an abnormal water level is detected, immediately suspend boiler operation and investigate the water level control system (such as the feedwater valve and water level sensor) for malfunctions. Restart the boiler only after the problem is resolved.

Strictly control water quality to reduce internal scaling and corrosion: Steam boiler water containing excessive calcium, magnesium ions, suspended matter, or dissolved oxygen can cause scale to form on the boiler's heating surfaces (such as the furnace water walls and convection tube bundles) over time. Scale has extremely low thermal conductivity (only 1/10-1/50 that of steel), reducing heat transfer efficiency and increasing fuel consumption (for every 1mm increase in scale thickness, fuel consumption increases by approximately 2%-5%). It can also cause corrosion and cracking of the tube walls due to localized overheating. Regularly (recommended 1-2 times per week, depending on frequency of use) test boiler feed water and boiler water for water quality indicators including hardness, pH, dissolved oxygen content, and suspended solids content to ensure they meet steam boiler operating requirements. Furthermore, specialized boiler water treatment agents (such as scale inhibitors and deoxidizers) should be added periodically. Regularly (every 3-6 months, depending on water quality) replace the water inside the boiler and perform blowdown operations to remove accumulated dirt and impurities, maintaining clean water quality.

The combustion system is the core of heat generation in industrial steam boilers. Its condition directly determines fuel utilization and steam production efficiency. Inspections of the burner, fuel supply piping, and ventilation equipment are particularly important.

Regularly clean the burner to ensure adequate combustion: Carbon deposits and oil accumulation on the burner can lead to abnormal flame shape (such as skewed or scattered flames) and incomplete combustion. This not only increases emissions of harmful gases such as carbon monoxide, but also wastes fuel and reduces steam production. Disassemble the burner casing weekly and use compressed air (pressure controlled at 0.3-0.5 MPa) to purge dust and carbon deposits from the nozzle, ignition electrode, and flame detector. Check the burner damper opening monthly to ensure the optimal air-fuel mixture ratio (typically 10:1-12:1 for gas boilers and 15:1-18:1 for oil boilers). This prevents incomplete combustion due to insufficient air and heat loss due to excessive air.

Check the fuel line seals to prevent leaks: Leaks in fuel (gas, oil) lines not only waste fuel but can also cause fires, explosions, and other safety hazards. Check the fuel line joints, valves, and flanges daily. Use soapy water to test for leaks. If bubbles are detected, immediately shut off the fuel supply valve and replace the seals or damaged lines. Reopen the fuel supply only after the leak has been resolved and safety has been confirmed. Fuel filters (such as the fuel filter screen and gas filter element) should be checked monthly for blockage. If impurities are found, they should be removed, cleaned, or replaced promptly to ensure a smooth fuel supply and prevent burner flameout or steam pressure drop due to insufficient fuel supply.

Maintain ventilation equipment to ensure air circulation: Steam boilers require sufficient air for combustion. Failure of ventilation equipment (such as induced draft fans and blowers) can lead to oxygen deprivation in the furnace, affecting combustion efficiency. Weekly checks should be conducted to ensure the operating status of induced draft fans and blowers is normal (no abnormal noise or vibration) and to check the motor casing temperature for excessive temperatures (usually no more than 80°C). Clean dust and debris from ventilation ducts monthly and check the air duct dampers for flexibility to ensure they can adjust air volume according to combustion requirements. This prevents blockages that could result in insufficient ventilation or damper jams that could affect air volume control.

Industrial steam boilers are pressure-bearing equipment. The reliability of pressure control and safety components is directly related to the safety of the equipment and personnel, and requires strict periodic inspection and calibration.

Monitor steam pressure in real time to avoid overpressure operation: Check the steam pressure every 30 minutes using the boiler's pressure gauges (main and backup) to ensure it remains within the rated operating pressure range (not exceeding 1.05 times the rated pressure). If an abnormally high pressure is detected, immediately open the safety valve to relieve pressure. Also, check the pressure control system (such as the pressure regulator and safety valve) for malfunctions. If the pressure continues to drop, investigate for steam line leaks or combustion system malfunctions, and promptly repair them. Furthermore, the pressure gauge should be calibrated monthly (this can be done by comparing it to a standard pressure gauge) to ensure accurate readings. If the gauge needle is stuck or the readings deviate beyond the allowable range, replace it immediately.

Regularly calibrate the safety valve to ensure reliable pressure relief: The safety valve is the "last line of defense" against overpressure in steam boilers. A malfunctioning safety valve can prevent timely pressure relief, potentially leading to boiler explosion. The safety valve should be manually opened once a month (a "manual steam exhaust test") to check whether it opens and closes smoothly and that the exhaust is unobstructed. Every six months (or as specified in the equipment manual), have a professional perform a comprehensive calibration of the safety valve, adjusting the trip pressure (usually 1.05-1.1 times the rated operating pressure) and the reseat pressure to ensure compliance with safe operating requirements. After passing the calibration, a calibration pass label should be posted, recording the calibration date and parameters.

Inspect other safety accessories to ensure proper function: In addition to the pressure gauge and safety valve, other safety accessories on the steam boiler (such as the water level alarm, pressure alarm, and emergency stop button) should also be inspected regularly. The water level alarm should be tested daily (simulating high and low water levels to verify that the audible and visual alarms sound promptly); the pressure alarm should be tested weekly (simulating overpressure to confirm proper function); and the emergency stop button should be checked monthly for sensitivity to ensure that pressing it immediately cuts off the fuel supply and stops the combustion system, preventing delays in emergency shutdowns. IV. Heating Surface and Insulation Maintenance: Key to Extending Steam Boiler Service Life

Damage to the heating surfaces (the areas that directly absorb heat to generate steam) and insulation (the areas that reduce heat loss) of a steam boiler will reduce thermal efficiency and shorten equipment life, requiring regular inspection and maintenance.

Clean the heating surfaces and remove ash and coke buildup: Ash or coke buildup on heating surfaces such as the boiler furnace and convection tube bundles can hinder heat transfer, increasing fuel consumption and reducing steam production. Clean the convection tube bundles monthly (or earlier, depending on operating conditions, if the exhaust gas temperature is abnormally high) with a high-pressure water jet (or compressed air). Inspect the furnace interior for coke buildup every three months (especially for oil- and coal-fired steam boilers). If coke is found, gently remove it with specialized tools (such as a steel chisel), avoiding excessive force that could damage the furnace refractory bricks or water-cooled wall tubes. After cleaning, inspect the heating surfaces for defects such as corrosion, bulging, and cracks. If any problems are found, immediately shut down the unit for repair. Operation with damage is strictly prohibited.

Check the insulation to reduce heat loss: Steam boilers are typically covered with insulation (such as rock wool or aluminum silicate fiber). Damaged or detached insulation can lead to significant heat loss (statistically, insulation damage increases boiler heat loss by 5%-10%). This not only wastes fuel but can also cause the furnace shell to overheat, potentially causing burns. Weekly checks should be conducted to ensure the integrity of the insulation on the furnace and steam pipelines. If damage or detachment is found, replace or repair it promptly. Measure the furnace shell temperature monthly (normally, it should not exceed 50°C). If the temperature is excessively high, investigate the insulation for potential problems and address them promptly.

An industrial steam boiler's electrical equipment (such as motors and control cabinets) and control systems (such as PLC controllers and touch screens) are central to automated operation. Their stability directly impacts the ease and reliability of boiler operation.

Maintain electrical equipment to prevent short circuits: Check the terminals inside the boiler control cabinet weekly for loose connections and tighten gently with a screwdriver (avoid excessive force to damage the terminals). Clean the control cabinet monthly (use dry compressed air to blow dust away). Check the contacts of contactors and relays for corrosion and oxidation. If damaged, replace them promptly. Check the insulation resistance of motors (induced draft fan, blower, and feedwater pump motors) every three months (measured with a megohmmeter; the insulation resistance should be no less than 0.5MΩ). If the insulation resistance is too low, dry the motor to prevent short circuits caused by insulation damage.

Verify the control system to ensure parameter accuracy: Check the boiler's operating parameters (such as water level, pressure, temperature, and fuel flow) monthly on the control system's touchscreen or operation panel to ensure they are consistent with the actual display. If any deviations are detected, calibrate the sensors (such as the water level sensor, pressure sensor, and temperature sensor). Check the PLC controller program every six months to ensure it is functioning properly and back up the control program to prevent control system failure due to program loss. In addition, the control system's automatic adjustment functions (such as automatic water level control and automatic pressure regulation) must be regularly tested to ensure that when the water level or pressure deviates from the set values, the control system can automatically adjust the opening of the feedwater valve and fuel valve to maintain stable boiler operation and reduce manual intervention.

Complete maintenance records and regular maintenance plans are crucial for promptly identifying potential steam boiler problems and avoiding sudden failures.

Maintaining Daily Maintenance Records and Tracking Operating Status: A "Daily Maintenance Record Form for Industrial Steam Boilers" should be established, detailing daily operating parameters (water level, pressure, temperature, steam production), maintenance details (such as water quality test results, burner cleaning, safety valve testing), and troubleshooting procedures (such as fault symptoms, repair measures, and repair time). Records must be truthful and accurate to facilitate subsequent tracing of equipment operating status and analysis of fault causes (for example, using historical water level data to determine whether the water level control system has a chronic fault), providing a basis for adjusting maintenance plans. Establish a regular maintenance plan to identify potential hazards: In addition to routine maintenance, quarterly and annual maintenance plans should be developed based on the age and operating intensity of the steam boiler. Quarterly inspections should focus on checking corrosion on heating surfaces, fuel line tightness, and electrical equipment insulation. Annual inspections require a complete disassembly and inspection of the boiler (such as opening manholes and handholes to check for internal scale and corrosion), replacement of aging components (such as seals, filter elements, and sensors), and a comprehensive calibration of safety accessories such as safety valves and pressure gauges. After the inspection is completed, a hydraulic pressure test (typically 1.25-1.5 times the rated operating pressure) is required to confirm that there are no leaks or deformation in the pressurized components before resuming operation.