Boilers for feed factories are key equipment to improve the quality and efficiency of feed processing, which can meet core needs such as sterilization, drying, and pellet conditioning.

The boiler used in feed factories primarily serves the following purposes:

Sterilization, Disinfection, Drying: The heat generated by the boiler can heat the feed to a certain temperature, achieving sterilization, disinfection, and drying, thereby improving the quality and palatability of the feed.

Improving Processing Efficiency: The steam provided by the boiler is used for conditioning raw materials in the pelletizing system. By heating and mildly drying the materials, it ensures that the material temperature and moisture content meet standards, thereby improving pelletizing efficiency and feed quality.

Pressure Stability and Continuity: Feed processing requires high-pressure stability and continuity of steam boilers to ensure that the temperature is controlled within an appropriate range, ensuring the quality of feed processing.

In summary, the boiler used in feed factories is a key equipment for improving the quality and efficiency of feed processing. It provides high-temperature steam to support various important processes in feed processing, such as pelletizing, conditioning, drying, and sterilization.

So, how to choose the right boiler for feed factories?

Boiler Model Selection used for Feed Factory Boiler

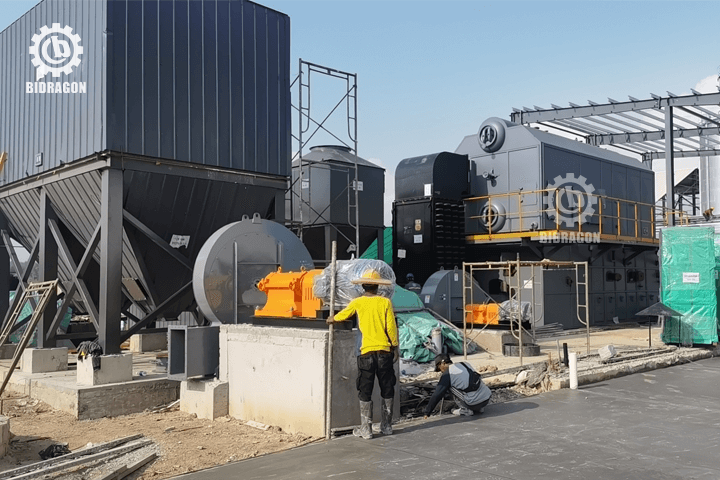

In general, considering the operating cost of boilers, Biomass Fired Boilers are most widely used in feed plants. Bidragon has various types of Biomass Boilers including manual burners, chain grate boilers and reciprocating grate. Bidragon Boiler could recommend and customize the appropriate biomass fired boilers according to the customers’ requirement. Currently, the boilers used in feed plant are gradually innovating with the reform of science and technology, and the new boiler system is gradually improving. Because of the large demand for feed, the selection of energy-saving and efficient boilers can greatly save fuel costs, Coal Fired Boilers and Gas Boilers have been gradually applied in feed mill.

Based on the above considerations, choose the most suitable boiler type. Common types include:

Fire-tube Boilers: Suitable for small to medium steam requirements, relatively easy to install and maintain.

Water-tube Boilers: Ideal for high-pressure applications and larger steam capacities, offering better efficiency and control.

Biomass Boilers: Suitable if biomass fuels are readily available and economical.

Steam Generators: Compact and efficient, suitable for specific applications with space constraints.