A biomass boiler is a type of thermal energy supply equipment that uses biomass as its core fuel. Its key feature is that it relies on renewable biomass resources (such as agricultural and forestry waste and biomass pellets) to replace traditional fossil fuels (coal, natural gas, and heavy oil). Through efficient combustion or gasification technology, the chemical energy in biomass is converted into thermal energy, providing a stable supply of steam, hot water, or high-temperature flue gas for industrial production. It is widely used in heating, drying, process heat, and power supply scenarios across various industrial sectors.

In terms of fuel characteristics, the fuel source for industrial biomass boilers is distinctly renewable. Common industrial-grade fuels include wood pellets, straw briquettes, bark, sugarcane bagasse, palm shells, furniture processing waste, and forestry residues. After pre-processing such as crushing and pelletizing, these fuels not only meet the boiler's requirements for continuous and stable combustion, but also significantly reduce industrial production's reliance on non-renewable fossil energy. They also reduce emissions of harmful gases (such as sulfur dioxide and nitrogen oxides) during combustion, aligning with the global trend of low-carbon transformation and sustainable development in the industrial sector.

In industrial applications, the core value of biomass boilers lies in their efficient adaptation to diverse production needs. Their industrial applications cover several key areas:

Manufacturing Heating and Drying: In industries such as textiles, printing and dyeing, papermaking, and food processing, biomass boilers provide continuous medium- and low-temperature steam or hot water for drying raw materials (such as textile fabric shaping and drying, paper drying), and heating production processes (such as sterilization and cooking in food processing). They meet the stringent temperature stability and continuity requirements of industrial production lines and, compared to traditional coal-fired boilers, reduce fuel storage space and transportation costs.

Chemical and Pharmaceutical Process Heat: Chemical and pharmaceutical production often requires steam at a specific temperature for core processes such as reactor heating and material purification. Industrial-grade biomass boilers enable precise regulation of steam pressure and temperature through precise combustion control systems, ensuring stable process parameters. Their low carbon emissions also help companies comply with environmental regulations and avoid the risks associated with burning fossil fuels. Heat supply for the building materials and metallurgical industries: In high-temperature industries such as cement, ceramics, and steel, biomass boilers can serve as auxiliary heating equipment, supporting raw material preheating (such as drying cement raw materials and ceramic bodies) and low-temperature heating. Some large-scale industrial biomass boilers, when combined with waste heat recovery systems, can also improve overall energy efficiency and reduce overall energy costs.

Centralized heating for industrial parks: For industrial parks with a concentration of multiple small and medium-sized industrial enterprises, biomass boilers can serve as the core equipment in centralized heating centers, supplying steam or hot water to all enterprises via a pipeline network, replacing the dispersed small coal- and oil-fired boilers of various enterprises. This not only reduces overall pollutant emissions in the park, but also reduces energy costs for each enterprise through large-scale fuel procurement.

From a technical perspective, industrial biomass boilers typically feature high combustion efficiency and robust load regulation. Modern industrial biomass boilers often utilize advanced combustion technologies such as stratified combustion, reciprocating grates, or circulating fluidized beds, fully utilizing the unique characteristics of biomass fuels and achieving combustion efficiencies exceeding 85%. Furthermore, the boiler itself and auxiliary systems (such as feeding and dust removal) are highly interconnected, allowing for flexible output adjustments based on real-time heat demand in industrial production, thus avoiding energy waste. Furthermore, with increasing global environmental protection requirements, industrial biomass boilers are often equipped with bag filters, desulfurization and denitrification equipment, and other devices to ensure that smoke and harmful gases emitted meet international environmental standards (such as EU EEA emission limits and US EPA standards), making them a crucial equipment choice for industrial enterprises in achieving their carbon reduction goals.

In summary, as an industrial thermal energy equipment that uses renewable biomass as fuel, biomass boilers have become key equipment in the global industrial field to replace traditional fossil fuel boilers and promote green production transformation due to their advantages of environmental protection, high efficiency and wide fuel sources. They play an irreplaceable role in heat supply in manufacturing, chemical industry, building materials, park heating and other scenarios.

Classification and Characteristics of Major Biomass Boiler Types

Biomass boilers can be categorized into various types based on fuel form, combustion technology, structural form, and industrial application scenarios. Each type of boiler focuses on fuel compatibility, thermal efficiency, and applicable scenarios. Especially in industrial applications, the choice of boiler type directly impacts the stability of production heat and energy efficiency. The following provides a detailed analysis of commonly used biomass boiler types in industry, based on core classification dimensions:

This is the most basic classification of biomass boilers. The fuel form directly determines the boiler's feed system design and combustion compatibility. Solid fuel-based boilers are predominant in industrial applications, with some using liquid or gaseous fuels as auxiliary fuels.

Solid biomass boilers: The most widely used type in the industrial sector, these boilers primarily use solid biomass resources as fuel, including unprocessed agricultural and forestry waste (such as wood chips, straw, bark, bagasse, and palm shells), as well as processed biomass pellets and briquettes. The core advantages of this type of boiler are its wide range of fuel sources, low cost, and suitability for most industrial production needs requiring medium- and low-temperature heat (such as drying and heating). They are commonly used in industries such as textiles, food processing, and building materials. They are typically equipped with specialized chain grates or reciprocating grates to ensure even distribution and combustion of the solid fuel. Some large industrial boilers also incorporate pre-treatment equipment such as crushing and screening to improve fuel combustion efficiency.

Liquid biomass fuel boilers: These boilers primarily use liquid biomass fuels, such as biodiesel and biooil (derived from biomass pyrolysis). These boilers are primarily used in industrial applications requiring high combustion stability and temperature control precision, such as heating small chemical reactors. Their advantages include more complete combustion, reduced pollutant emissions, and the elimination of complex solid fuel transportation and storage systems. However, due to the production cost and supply scale of biomass liquid fuels, their industrial application scope is smaller than that of solid fuel boilers.

Gas biomass fuel boiler: The fuel is combustible gas produced by biomass gasification (such as biogas and gasification gas). Solid biomass is converted into a gas containing methane and carbon monoxide in a gasifier, which is then fed into a boiler to generate heat. This type of system is commonly used in industries with centralized biomass waste processing needs (such as large farms and paper mills), enabling "waste resource utilization." However, it places high demands on gas purity and the sealing of the delivery system, making it suitable for areas with extremely stringent environmental standards.

Combustion technology is the core factor determining the thermal efficiency and environmental performance of biomass boilers. Different technology approaches are suitable for different fuel characteristics. Layer-fired and fluidized-bed combustion technologies are predominant in industrial applications, while gasification combustion technologies are often used in applications with specific environmental requirements.

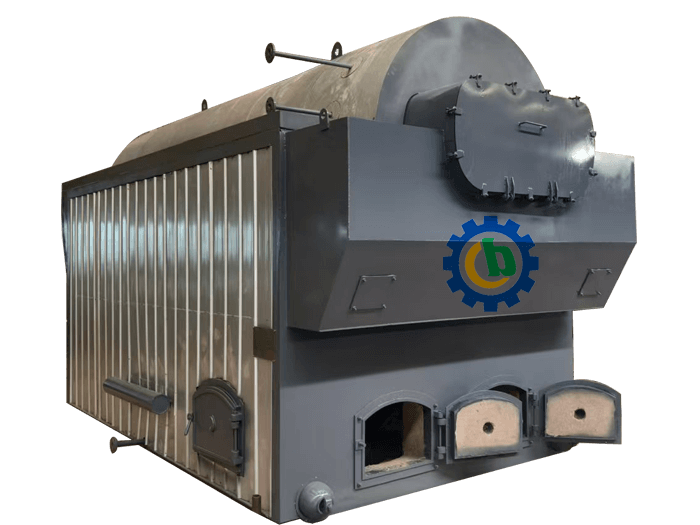

Layer-fired biomass boilers (fixed grate/chain grate boilers): The most common type in industry, these boilers utilize the principle of "layered fuel combustion." Solid fuel is evenly distributed on the grate via a feeder, and air is introduced from below the grate, ensuring full contact with the fuel for combustion. Chain grate biomass boilers, due to their ability to continuously deliver fuel and automate the combustion process, are more suitable for continuous industrial production needs (such as centralized heating in industrial parks and drying processes in paper mills). They can accommodate preformed fuels such as pellets and briquettes, achieving combustion efficiencies of 80%-85%. Fixed grate boilers, on the other hand, are primarily used in small industrial settings or for intermittent heating needs. They are relatively simple to operate, but their fuel adaptability is narrower.

Circulating fluidized bed biomass boiler:Using high-temperature fluidized bed combustion technology, solid fuel is crushed into fine particles, which are then mixed with high-velocity hot air in a fluidized state within the furnace for combustion. Unburned fuel particles are recovered through a separator and re-entered into the furnace for secondary combustion. This type of boiler offers advantages in fuel adaptability (combining various agricultural and forestry wastes, even low-calorific value waste residues), high combustion efficiency (over 90%), and the ability to reduce pollutant emissions through in-furnace desulfurization and other technologies. It is widely used in industries with high heat demand and complex fuel sources, such as the chemical, metallurgical, and building materials industries.

Biomass gasification boilers: These are indirect combustion boilers. A gasification unit converts solid biomass into biomass fuel gas, which is then fed into the boiler furnace for combustion and heat generation. Their key features include cleaner combustion (gas combustion is virtually smokeless) and extremely low pollutant emissions, making them suitable for environmentally conscious industrial applications such as pharmaceutical manufacturing and food processing. However, they require a complex system structure (a gasifier and gas purification equipment are required), a high initial investment, and strict requirements for the moisture and impurity content of the biomass fuel.

The structural type is primarily determined by the boiler's heating surface layout and pressure rating, which directly influences the boiler's output and applicable industrial applications. Water-tube boilers are predominant in industry, while fire-tube boilers are primarily used for smaller heating needs.

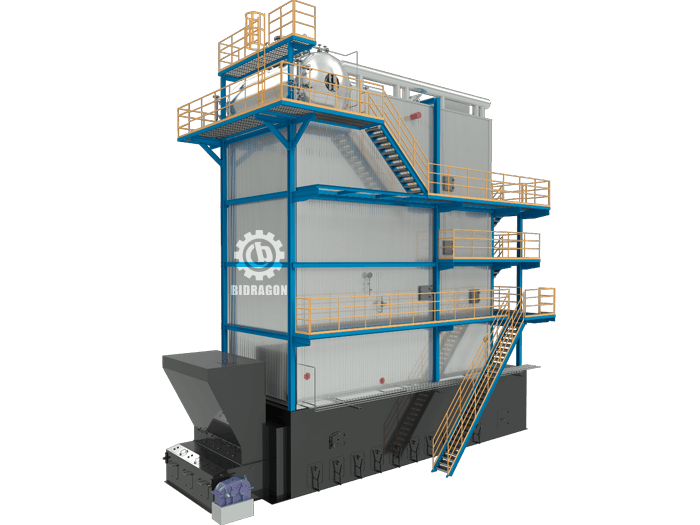

Biomass water-tube boilers: The heating surface is primarily composed of water tubes, with water flowing within the tubes while the flame and high-temperature flue gas rub and exchange heat outside the tubes. This type of boiler offers advantages such as high thermal efficiency, high output (it can provide high-pressure steam to meet the needs of large-scale industrial production), and strong load regulation, adapting to fluctuating heat demand in industrial production lines. It is commonly used in large chemical plants, steel mills, and centralized heating parks. Its structural design allows for flexible adaptation to various combustion technologies, such as circulating fluidized beds and chain grates, making it a top choice for large-scale industrial heating applications.

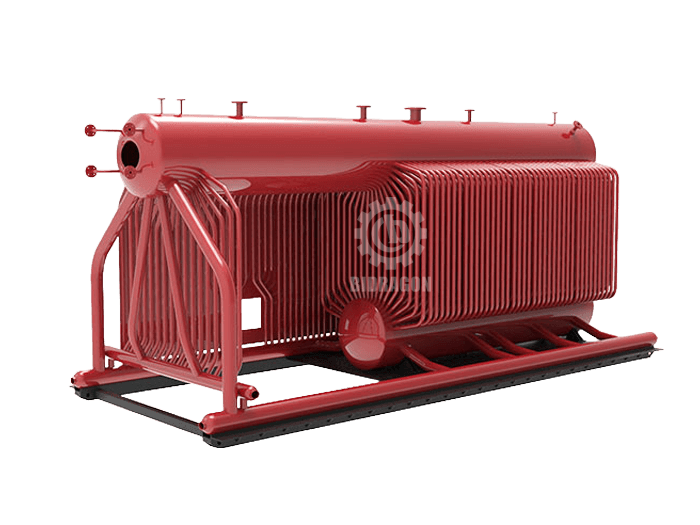

A biomass fire tube boiler (shell and tube boiler): The heating surface is primarily composed of fire tubes, with high-temperature flue gas flowing through the tubes while water is heated within the shell surrounding the fire tubes. This type of boiler offers a simple structure, compact size, and fast startup, but with lower output and pressure, making it suitable for small industrial applications (such as drying and heating needs in small food and garment factories). It is typically equipped with a fixed grate or a small chain grate, and the fuel is typically biomass pellets or small lumps.

Based on actual industrial application needs, these boilers are segmented by output scale and heat usage scenarios to precisely match the production needs of different industries:

Small-sized industrial biomass boilers (output ≤ 10 t/h): These are primarily used for intermittent or low-load heating in small and medium-sized enterprises, such as steaming in food processing, fabric shaping in the textile industry, and raw material drying in small building materials factories. They typically utilize chain grates or fixed grates, primarily fueled by biomass pellets and briquettes. They offer low investment costs and easy operation.

Medium-sized industrial biomass boilers (output 10-40 t/h): These boilers are suitable for the continuous heating needs of medium-sized industrial enterprises, such as process heating in medium-sized chemical plants, pulp drying in paper mills, and decentralized heating in industrial parks. They typically utilize circulating fluidized bed or large chain grate technology, are compatible with a variety of solid biomass fuels, and offer a balance of thermal efficiency and stability.

Large-scale industrial biomass boilers (output ≥ 40t/h): They are mainly used in high-load, continuous heat usage scenarios in large industrial enterprises or centralized heating centers, such as waste heat replenishment in steel mills, raw material preheating in large cement plants, and centralized steam supply in urban industrial parks. Almost all of them use circulating fluidized bed combustion technology and are equipped with a complete fuel pretreatment system and environmental protection equipment. They can achieve efficient and clean combustion of large-scale biomass fuels and meet the continuous and stable supply of heat energy required by industrial production.

This type of fuel is derived from natural waste generated during agricultural production and forestry processing. It requires no additional cultivation costs, is readily available, and is a mainstream fuel for industrial biomass boilers, particularly suitable for grate-fired and circulating fluidized bed boilers.

Agricultural waste fuel:This includes harvested rice, wheat, and corn straw (e.g., corn stalks and wheat straw), rice husks, and cotton stalks and bagasse from cotton and sugarcane processing. Rice husks and bagasse, due to their high density, relatively stable moisture content (typically 15%-25%), and moderate calorific value (approximately 12-16 MJ/kg), are often used directly as boiler fuel by large-scale food processing and sugar refineries, achieving on-site resource utilization of production waste. Straw fuel, however, requires crushing and compression (to prevent fluffiness that can lead to incomplete combustion) and is primarily used in small and medium-sized industrial boilers, meeting the medium- and low-temperature heating needs of industries like textiles and building materials.

Forestry waste fuel: Primarily derived from wood processing and pruning, such as sawdust, bark, branches, and wood chips, as well as scraps from furniture manufacturing and plywood waste, is used. This fuel has a high lignin content, resulting in a high calorific value (approximately 16-20 MJ/kg), a low ash content (typically <5%), and is less prone to coking, making it suitable for long-term, stable supply to industrial boilers (such as paper mills and wood-based panel manufacturers). Sawdust, due to its uniform particle size, can be directly used as a feedstock for biomass pellet fuel or burned directly in chain grate boilers, making it a core fuel for achieving energy self-sufficiency in forestry processing enterprises.

Pelletized fuel is a fixed-form fuel created by mechanically compressing and shaping loose agricultural and forestry waste (such as straw and sawdust). This addresses the issues of natural waste, such as bulk, difficulty in transportation, and low combustion efficiency, and is a standardized fuel option for industrial biomass boilers, particularly those with a high degree of automation.

Biomass pellet fuel: After raw materials such as sawdust and straw are crushed, they are extruded into cylindrical pellets with a diameter of 6-10mm and a length of 10-30mm using a pellet mill. The moisture content is controlled at 8%-15%, and the calorific value is stable at 18-22MJ/kg. Its advantages include high density (approximately 1.1-1.3 tons/m³), easy storage and transportation, complete combustion, and low ash production. It is suitable for industrial chain grate boilers and small circulating fluidized bed boilers, and is widely used in food drying, chemical heating, and centralized heating in industrial parks. It enables automated boiler feeding and precise temperature control.

Biomass briquette fuel: Raw materials are compressed into briquettes (commonly square or cylindrical, and larger in size, such as 50mm×50mm×100mm). The density is approximately 0.8-1.0 tons/m³, and the calorific value is slightly lower than that of pellet fuel (approximately 16-19MJ/kg), but the production cost is lower. It is suitable for industrial enterprises with sufficient raw material supply (such as large farms and straw processing bases). Briquetted fuel requires no complex crushing and can be directly burned in grate-fired boilers. It is often used in fuel-cost-sensitive, large-scale heat-consuming applications (such as drying in building materials factories and supplementary combustion in small power plants).

Biomass rod fuel: Wood raw materials (such as sawdust and bamboo chips) are pressed into rods with a diameter of 20-50mm using a high-pressure briquetting machine. They have a high density (approximately 1.2-1.4 tons/m³) and a high calorific value (approximately 20-23 MJ/kg). During combustion, they offer a stable, long-lasting flame, making them suitable for industrial applications requiring high thermal stability (such as ceramic firing and metal heat treatment). However, due to the high briquetting pressure, the raw material must be primarily pure wood, making their application slightly narrower than that of pellet and briquette fuels.

Energy crops are crops grown specifically for biomass energy production. They feature a short growth cycle, high yield, and stable calorific value, making them suitable for long-term, stable energy supply to large-scale industrial biomass boilers. They are particularly popular in areas with abundant agricultural resources.

Herbaceous energy crops:Such crops as sweet sorghum, Miscanthus sinensis, and switchgrass grow rapidly and can be harvested multiple times a year. Their straw has a low moisture content (dried to about 15% after harvesting) and a combustion calorific value of about 13-17MJ/kg. They can be directly crushed and used as circulating fluidized bed boiler fuel, or processed into pellet fuel for industrial parks. The stalks of sweet sorghum can also be squeezed to extract biomass fuel, and the residue can still be used as boiler fuel, achieving "whole plant utilization."

Wooden energy crops:Fast-growing trees like poplar, eucalyptus, and jatropha have high wood density, a calorific value of 18-22 MJ/kg, and a short growth cycle (harvesting after 5-7 years), making them suitable for use in industrial boilers within forestry bases. Wood fuel, after being crushed into chips or processed into pellets, is compatible with a variety of industrial boilers, including chain grates and circulating fluidized beds. It provides a long-term, stable fuel source for large-scale biomass power plants and centralized heating centers.

The operating temperature and pressure of biomass boilers are not fixed values. Key factors depend on the boiler's design application, fuel type, heating surface structure, and industrial production's demand for steam/hot water. These parameters vary significantly across different application scenarios. The following details the core operating temperature and pressure ranges and influencing factors for common industrial boiler types (steam boilers and hot water boilers) and their typical applications.

In industrial scenarios, biomass steam boilers primarily produce saturated or superheated steam. Temperature and pressure are directly linked (in the saturated steam state, increasing pressure increases the temperature). They are primarily categorized as low-medium pressure and medium pressure. High-pressure applications are less common (due to the calorific value of the biomass fuel and boiler design costs).

Low-medium Pressure Biomass Steam Boilers (Most Widely Used)

Pressure Range: Typically 0.7MPa - 2.5MPa (gauge pressure), meeting the "low-parameter steam" requirements of the industrial sector and suitable for heating, drying, disinfection, and other applications in most light and manufacturing industries. For example, food processing plants use steam in this pressure range for grain drying and sauce sterilization, textile mills use it for fabric shaping, and chemical plants use it for distilling low-boiling-point materials.

Temperature Range:

For saturated steam: At a pressure of 0.7 MPa, the temperature is approximately 164°C; at a pressure of 2.5 MPa, the temperature is approximately 223°C, meeting the requirements of medium- and low-temperature processes (most industrial heating does not require temperatures exceeding 250°C).

For slightly superheated steam (in some boiler designs), the temperature is 30°C-50°C higher than saturated steam at the same pressure. For example, at a pressure of 2.5 MPa, superheated steam can reach temperatures of 250°C-270°C. It is primarily used in applications requiring high-dryness, moisture-free steam (such as driving small turbines and heating precision equipment) to prevent moisture-induced corrosion and reduced efficiency.

Medium-Pressure Biomass Steam Boiler (Suitable for High-Load Industrial Scenarios)

Pressure range: Generally 3.82MPa - 5.29MPa (gauge pressure), classified as "medium-pressure steam," primarily used in heavy industry or energy recovery scenarios with higher steam and heat requirements.

For example, large-scale biomass thermal power plants (with accompanying steam turbine generators for power generation), building materials plants (for preheating cement clinker calcination), and paper mills (for drying large paper machines) require higher-pressure steam to improve thermal efficiency and reduce energy consumption per unit of product.

Temperature Range:

For saturated steam, 3.82 MPa corresponds to approximately 247°C, and 5.29 MPa corresponds to approximately 264°C.

For superheated steam (required for thermal power plants), the temperature can be raised to 350°C-450°C. For example, at 5.29 MPa, the superheated steam temperature can reach approximately 400°C, meeting the "high-temperature, high-pressure steam" energy requirements of steam turbine power generation. The higher the steam temperature, the higher the turbine's power generation efficiency (in line with the Rankine cycle principle).

High-Pressure Biomass Steam Boiler (Rarely Used)

Pressures typically exceed 9.8 MPa and temperatures exceed 450°C. Because the calorific value of biomass fuel (generally lower than coal and natural gas) cannot sustain the heat output under high-pressure conditions, and the boiler material and safety control requirements are extremely stringent, this type of boiler is only used in a few specialized industrial projects supporting biomass gasification systems (converting biomass into gas for combustion) and is not a mainstream application.

Industrial biomass hot water boilers are primarily designed to provide high-temperature hot water. Temperature and pressure are not directly related (hot water is liquid, and pressure primarily serves to ensure water circulation, not to increase temperature). Pressure is typically low, with temperature adjusted based on process requirements. They are primarily used in applications such as central heating and industrial heat exchange.

Pressure Range:

Most are between 0.4MPa and 1.6MPa (gauge pressure), classifying them as "low-pressure hot water boilers." The core purpose of pressure design is to ensure stable circulation of hot water within the pipe network (especially in high-rise buildings or when transporting it over long distances), preventing gas locks and flow interruptions.

For example, industrial parks with central heating covering multiple factory buildings, chemical plants using reactor jacket heat exchange (heat is transferred through hot water rather than direct contact with the product), and slaughterhouses using hot water for hair removal all utilize this pressure range, meeting water circulation requirements while reducing boiler pressure design costs.

Temperature Range:

Conventional industrial hot water temperature: 95°C - 130°C. For example, central heating requires hot water to be heated to 95°C - 110°C and then piped to factory radiators via a network. Chemical heat exchange requires hot water at 110°C - 130°C to provide a stable heat source for low-temperature reactions.

High-temperature hot water boilers (for special needs): Temperatures can be raised to 130°C - 180°C, but require a "pressurized hot water system" (pressure must be simultaneously increased to 1.6MPa - 2.5MPa) to prevent hot water from vaporizing at high temperatures. (Above 100°C, hot water at normal pressure will boil and vaporize, causing a sudden increase in pipe pressure.) These boilers are primarily used in applications requiring high hot water temperatures, such as high-temperature dyeing in textile factories and high-temperature cleaning in food factories.

Fuel Characteristics: The calorific value of biomass fuels (such as pellets, straw, and sawdust) is generally 12-23 MJ/kg, lower than coal (25-30 MJ/kg) and natural gas (35-40 MJ/kg). Therefore, it is difficult for boilers to maintain ultra-high pressures (e.g., above 9.8 MPa) and temperatures (e.g., above 450°C) for extended periods. Failure to do so would significantly increase fuel consumption, leading to higher operating costs.

Industrial Heat Demand:Temperature and pressure settings must match downstream processes. For example, food processing only requires saturated steam at 160-220°C, eliminating the need for high parameters. In contrast, biomass thermal power plants must utilize superheated steam at 350-450°C to improve power generation efficiency, necessitating tailored boiler heating surface design (e.g., adding a superheater).

Boiler structure design: A biomass boiler equipped with a "superheater" can raise the steam temperature to over 350°C, while a boiler with only a "steam drum" can only produce saturated steam. If a hot water boiler adds a "coil-type heating surface", the hot water temperature can be raised to 180°C, otherwise it can only be maintained below 130°C.

Key Points for Daily Maintenance and Care of Biomass Boilers

Daily maintenance and care for industrial biomass boilers is crucial for ensuring long-term stable operation, reducing downtime, and extending service life. This requires focusing on the four core components: the fuel system, combustion system, heat exchange system, and auxiliary equipment. Targeted care should be taken into account the characteristics of biomass fuel (which is prone to coking and has a high ash content). Specific key points are as follows:

The fuel system (storage silo, feed conveyor, and impurity removal device) is the fuel supply to the boiler. Improper maintenance at the source can easily lead to fuel interruptions, directly impacting boiler operation. Key areas for attention include:

Regular inspection and cleaning of the storage silo

Check the fuel silo daily for signs of bridging or clumping (biomass fuel absorbs moisture and tends to clump, potentially blocking the discharge port). If lumps are found, break them up immediately with specialized tools to prevent unloading.

Open the inspection door at the bottom of the silo weekly to remove any remaining fuel debris and impurities (such as stones and metal fragments) to prevent them from entering the feeder and causing equipment jams.

Inspect the silo's moisture-proof and ventilation features (such as the sealing of the rain cover and the sidewall vents) monthly to ensure the fuel moisture content remains within the optimal range of 15%-20% to prevent mold or spontaneous combustion.

Daily Lubrication and Adjustment of Feeding Equipment

Before daily startup, inspect the transmission components (such as bearings and chains) of the screw conveyor and scraper conveyor and add specialized lubricant (select the type according to the equipment manual) to prevent dry friction and component wear.

During operation, inspect the feeder for uniform conveying speed. If there is a break or blockage, immediately stop the machine and inspect the feed inlet for foreign matter, or adjust the conveyor speed to match the boiler load.

Weekly, disassemble and inspect the feeder's impurity removal devices (such as magnetic separators and screens) to remove adsorbed metal impurities and large foreign matter to prevent them from entering the furnace and scratching the grate or causing coking.

The combustion system (furnace, grate, and ignition device) is the core of a boiler's heat generation. Biomass fuel combustion easily produces ash and coke. Failure to clean them promptly can reduce thermal efficiency and even damage the furnace. Key areas to focus on include:

Regular cleaning of the furnace and grate.

Daily after the boiler is shut down (wait until the furnace temperature drops below 150°C), open the furnace door and clean the coke layer on the furnace wall. A special scraper can be used to remove the layer, avoiding damage to the furnace bricks due to hard knocks.

If the coke is severe (thickness exceeding 150°C), the furnace door should be cleaned. 50mm), high-pressure air blowing or mechanical crushing is required to prevent coking from affecting heat conduction.

Check the grate gap and operating status weekly, and clean the ash hopper below the grate (excessive ash in the hopper can block the ventilation holes, resulting in insufficient oxygen supply to the furnace). Also, check the tension of the grate drive chain. If loose, adjust it promptly to prevent the grate from deviating or jamming.

Inspect the furnace refractory bricks and castables monthly. Any cracks or peeling should be repaired promptly with high-temperature repair materials to prevent high-temperature flue gas leakage and burns to equipment or personnel.

Ignition and air distribution system inspection and commissioning

Test the ignition system (such as the ignition electrode and fuel/gas igniter) daily before startup to ensure sufficient spark intensity and accurate ignition position to avoid fuel accumulation and explosions caused by ignition failure.

Regularly check the air volume and pressure of the blower and induced draft fan during operation, and adjust the air distribution ratio based on furnace combustion conditions (typically, an excess air ratio of 1.2-1.5 is required for biomass combustion). This prevents incomplete combustion (black smoke) caused by insufficient air volume, or heat loss caused by excessive air volume.

Clean the blower inlet filter and the duct baffle at the induced draft fan outlet weekly to prevent dust blockage that affects ventilation efficiency. Also, check the fan bearing temperature (normally no more than 70°C). If the temperature is excessively high, shut down the machine and inspect for oil shortages or bearing wear.

The heat exchange system (water walls, convection tube bundles, economizer, and air preheater) is responsible for transferring heat from the furnace to water or air. If scale and soot accumulate on these surfaces, heat exchange efficiency will be significantly reduced and energy consumption will increase. Therefore, the following priorities must be addressed:

Water Quality Management and Scale Removal

Daily monitor boiler feed water quality indicators (such as hardness and pH value. Industrial boilers generally require a feed water hardness of ≤0.03 mmol/L and a pH of 10-12). Ensure the proper operation of water treatment equipment (such as softeners and deaerators) to prevent scale formation from calcium and magnesium ions in the heat exchange tubes.

Every 3 days, Perform chemical descaling on the boiler body (water walls and convection tube bundles) every month (or depending on water quality). Use a dedicated descaling agent (such as citric acid or hydrochloric acid solution) for cyclic cleaning to remove scale from the tube walls. After cleaning, rinse thoroughly with clean water and then perform a passivation treatment to prevent tube wall corrosion.

Check the economizer inlet and outlet water temperature difference monthly. If the temperature difference decreases (normal temperature difference should be ≥15°C), it indicates excessive dust accumulation on the outside of the economizer tubes and requires cleaning with high-pressure water or compressed air to restore heat exchange efficiency.

Cleaning the Flue and Heat Exchange Components

Open the flue inspection door weekly to clean ash deposits on the convection tube bundle and air preheater surfaces (biomass fuel contains approximately 5%-15% ash, which easily accumulates on the heat exchange tube surfaces). Mechanical vibration or high-pressure air blowing can be used to prevent ash deposits exceeding 3mm in thickness (excessive ash accumulation can reduce thermal efficiency by 5%-10%).

Check the seals of the flue dampers monthly. Replace the gaskets if leaks are detected to prevent cold air from entering the flue and lowering the exhaust temperature (normal exhaust temperature should be controlled between 150-200°C), thereby minimizing heat loss. Also, check the chimney for rain and corrosion protection to prevent rainwater from entering the flue and causing rust.

The auxiliary equipment of industrial biomass boilers (water pumps, oil pumps, control systems, and safety valves) is the "guarantee" of safe operation and requires regular inspection and commissioning:

Power Equipment (Water Pumps, Oil Pumps) Maintenance

Check the inlet and outlet pressures of the feed and circulating water pumps daily (normal pressures should meet the equipment manual requirements). Observe the pumps for leaks and unusual noises. If any abnormalities are detected, shut down the pumps and inspect the seals or bearings.

Inspect the water and oil pump motors weekly, measure the motor winding temperature (normally no more than 80°C), clean dust from the motor surface, and check for loose terminals to prevent overload and burnout.

Replace the lubricating oil in the water and oil pumps monthly (regular changes are recommended depending on the oil type, such as 46# anti-wear hydraulic oil). Also, check the concentricity of the couplings to prevent excessive vibration caused by misalignment.

Safety and Control System Inspection

Before daily startup, test the safety valve and pressure gauge for effectiveness: Manually open the safety valve to release pressure and ensure the valve core is flexible. Check that the pressure gauge pointer is at zero. If the pointer is stuck, replace the pressure gauge (the pressure gauge should be calibrated annually to ensure accuracy).

Weekly, check the operating status of the PLC control system, clean dust from the control cabinet, check for loose connections, and test the accuracy of temperature and pressure sensor signals (such as the furnace temperature sensor and steam pressure sensor) to prevent signal distortion and control errors.

Monthly, test the emergency stop button and alarm devices (such as the over-temperature alarm and over-pressure alarm) to ensure that they immediately cut off the fuel supply and stop the fan when triggered, ensuring the safety of equipment and personnel.

Establish a maintenance log: Detailed records of daily, weekly, and monthly maintenance activities (such as cleaning time, replaced parts, and parameter test results) are kept to facilitate equipment operational status tracking and proactively identify potential faults.

Perform maintenance regularly: Strictly follow the equipment manual and industry standards to establish maintenance schedules to prevent minor faults from escalating into major problems due to "delayed maintenance" (e.g., minor coke buildup left unremoved can develop into a furnace blockage, requiring a major overhaul).

Professional Operation: Professional operations such as furnace cleaning, chemical descaling, and safety valve calibration must be performed by certified personnel to avoid equipment damage or safety incidents caused by improper operation.

Through these targeted daily maintenance and care, the failure rate of industrial biomass boilers can be effectively reduced (typically, annual downtime can be limited to less than 50 hours), equipment thermal efficiency can be maintained (ensuring a stable thermal efficiency above 80%), and equipment lifespan can be extended (with proper maintenance, industrial biomass boilers can have a lifespan of 10-15 years), providing reliable assurance for continuous industrial production.

Industrial Biomass Boiler Application Industry Detailed Explanation

Industrial biomass boilers are highly efficient heating equipment fueled by renewable biomass sources such as biomass pellets, straw, wood chips, and palm shells. With their environmentally friendly and low-cost advantages, they are widely applicable to production heating needs across multiple industrial sectors. Key applicable industries are as follows:

Manufacturing is one of the primary application scenarios for industrial biomass boilers, particularly for various production processes requiring a stable steam or hot water supply. In the textile printing and dyeing industry, industrial biomass boilers provide continuous high-temperature steam, meeting the temperature requirements of fabric dyeing, shaping, and drying processes, ensuring consistent fabric processing quality. In the papermaking industry, the entire process from pulping to paper drying requires significant heat energy. Steam generated by boilers can be used to heat the pulp, drive drying drums, and assist in paper forming and moisture control. In the plastics and rubber manufacturing industry, boilers provide heat for melting raw materials, vulcanizing finished products, and cooling and shaping them, facilitating the large-scale production of various plastic products (such as pipes and injection molded parts) and rubber products (such as tires and seals). Furthermore, the hardware processing and machinery manufacturing industries also utilize steam or hot water generated by boilers for parts cleaning, surface treatment (such as preheating before painting), and equipment insulation, improving production efficiency.

This industry places extremely high demands on the safety and stability of heating. The clean combustion characteristics of industrial biomass boilers meet these production standards. In the food processing sector, steam generated by boilers can be used for canning, heating and mixing beverages, high-temperature baking of baked goods, and preheating and sterilizing raw materials in dairy production, among other key processes, to prevent fuel impurities from affecting food hygiene. In the agricultural product processing industry, the drying of grains such as rice, wheat, and corn requires continuous and gentle heat. Biomass boilers can precisely control temperature and minimize nutrient loss. Furthermore, oil mills (such as those producing palm oil and soybean oil) use steam to heat raw materials to increase oil yield, while sugar mills (such as those producing cane and beet sugar) rely on steam for sugar extraction and concentration. Industrial biomass boilers can efficiently meet these needs.

Chemical and pharmaceutical production often require heat at specific temperatures to drive reactions or process materials. Industrial biomass boilers can provide customized heating solutions. In the chemical industry, small and medium-sized chemical plants producing products such as coatings, adhesives, and dyes rely on boiler steam to heat reactors and maintain the stable temperature required for chemical reactions. Some fine chemical companies also use hot water generated by boilers to dissolve and purify materials, reducing production energy consumption. In the pharmaceutical industry, the sterilization process of pharmaceutical production (such as high-temperature sterilization of oral liquids and injectables) requires high steam purity. The clean combustion steam generated by biomass boilers can meet GMP production standards, and their controllable heating capacity is also suitable for the small-batch heating needs of different pharmaceutical research and development.

Building materials production is a high-energy-consuming industry. The high heat conversion efficiency of industrial biomass boilers can effectively reduce production costs. In the cement manufacturing industry, high-temperature steam generated by boilers can be used for preheating and drying cement raw materials, as well as for auxiliary heating in cement kilns, improving raw material calcination efficiency. In the ceramic and brick and tile industries, continuous heat energy is required for everything from dehydration and drying of raw material mixing to firing ceramic bodies and forming and drying bricks and tiles. Biomass boilers can adjust heating parameters based on the firing temperature requirements of different building materials (e.g., ceramics require temperatures above 1200°C, bricks and tiles require 800-1000°C), adapting to diverse production needs. Furthermore, the production of new building materials (such as insulation boards and gypsum boards) relies on stable heat from boilers for processes such as raw material curing and board drying. The environmentally friendly properties of biomass energy can also help building materials companies reduce carbon emissions, aligning with green production trends.

Industrial biomass boilers also offer significant advantages in industrial district heating and small- and medium-sized cogeneration projects. For centralized heating in industrial parks, boilers can generate high-temperature hot water or steam, which can be used to provide production heat and office area heating to multiple companies in the park through a pipeline network, reducing the heating equipment investment cost of individual companies. Small and medium-sized cogeneration projects in some areas will use industrial biomass boilers to generate electricity using the heat energy generated by combustion to meet the basic electricity needs of companies in the park. At the same time, the waste heat generated during the power generation process can be used for heating, realizing "electricity + heat" cogeneration and improving the comprehensive energy utilization rate. This is especially suitable for promotion and application in areas with rich biomass resources (such as surrounding agricultural production areas and wood processing plants).