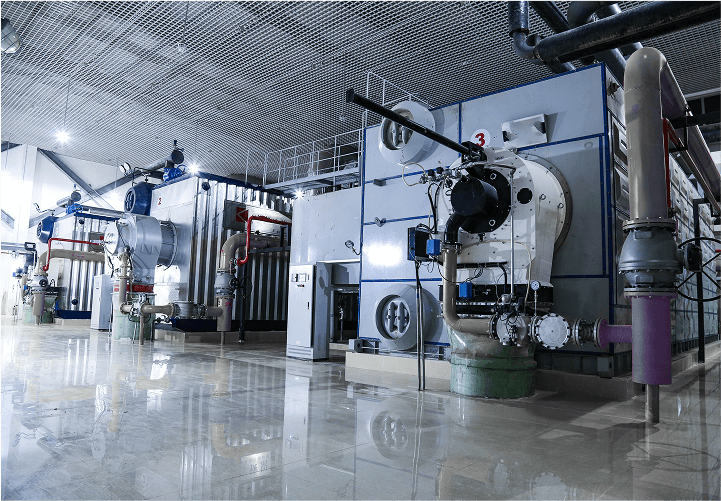

DZH/DZG series package fire-tube & water-tube boiler, it's manual feed type boiler with travelling grate/fixed grate. Horizontal jute fired boiler capacity in 1ton-10ton. Strong work pressure power to supply steam heat for garments factory.

Steam Capacity:100kg-10000kg

Fuel:Jute, Waste Fabric/clothes, Coal, Wood, Biomass, Solid material

Structure:Horizontal

Usage: Bangladesh Garments Textile factory, Industrial Processing

| Model | DZH1 | DZH2 | DZH4 | DZH5 | DZH6 | DZH8 |

| Rated Steam Capacity(t/h) | 1 | 2 | 4 | 5 | 6 | 8 |

| Rated Working Pressure(Map) | 1 | 1.0/1.25/1.6 | 1.25/1.6 | 1.25 | 1.25/1.6/2.5 | 1.25 |

| Rated Steam Temp.(℃) | 184 | 184/194/204 | 194/204 | 194 | 194/204/226 | 194 |

| Feed-water Temp.(℃) | 20 | 20 | 20 | 20 | 20 | 20 |

| Boiler proper heating area(m2) | 40.8 | 47.74 | 93.67 | 118.25 | 154.334 | 188.475 |

| Economizer heating area(m2) | 8.28 | 16.56 | 43.2 | 78.2 | 78.2 | 130.8 |

| Water Volume(m3) | 3.6 | 4.9 | 9.2 | 8.4 | 9.5 | 13.8 |

| Design Efficiency (%) | >82 | >82 | >82 | >82 | >82 | >82 |

| Design of Fuel | Biomass, Jute, Waste Fabric, Wood fired | |||||

| Fuel Consumption (kg/h) | 175 | 350 | 700 | 952 | 1048 | 2578 |

| Boiler Body Size(L*W*H)(m) | 5.1*2.1-2.6 | 4.8*2.5*3.5 | 6.0*2.9*3.6 | 5.5*3.2*3.5 | 6.2*3.4-3.5 | 7.2*3.2*3.8 |

| Total Weight(t) | 12 | 15.3 | 28 | 23.5 | 25.3 | 40.3 |

| Item | Low Heat Value |

| II Class Bituminous | 4500-5000 kcal/kg |

| Pellet | 3000-4200 |

| Wood Chip(oak) | 3830 kcal/kg |

| Rick Husk | 2600-3600 kcal/kg |

| Pale Shell | 2997 kcal/kg |

| Item | Low Heat Value |

| Coconut Shell | 3885 kcal/kg |

| Sawdust | 3120 kcal/kg |

| Bagasse | 1665 kcal/kg |

| Corn Cobs | 4241 kcal/kg |