May 26, 2020

3500kW Molten Salt Furnace Shipped

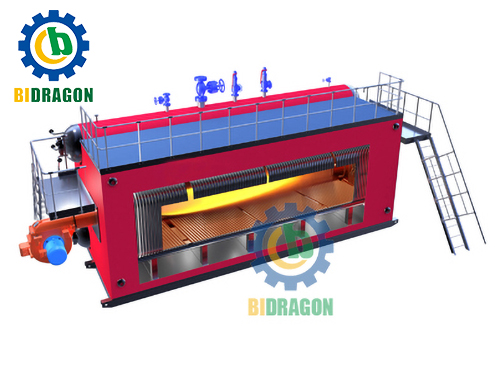

A 3500kW molten salt furnace was successfully prepared and shipped despite delays caused by the pandemic. This marks the second cooperation with our valued customer. To ensure quality assurance, detailed photos of the furnace and components were shared for inspection. The shipment required three containers: FR (furnace body, outrigger), OT (molten salt pump, heating tubes, chimney, explosion-proof door, top cover, small body), and 40’ container (burner, spare parts, control cabinet, storage tank). Bidragon continues to provide high-quality furnaces and professional service.