Mar 16, 2022

How to Choose Natural Gas Fired Thermal Oil Boiler

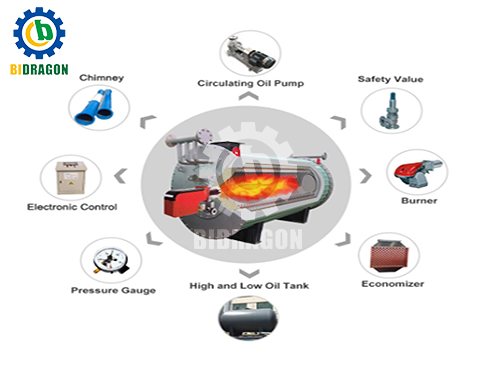

When purchasing a gas thermal oil boiler, it’s important to understand the main equipment, auxiliary equipment, meters, valves, water treatment, and control systems. Learn how to inspect electrical cabinets, consoles, frequency converters, monitoring systems, anti-riot devices, and oil tanks. Ensure flaw detection and debugging before delivery, and evaluate costs including boiler price, installation materials, labor, transportation, and spare parts for safe and efficient operation.