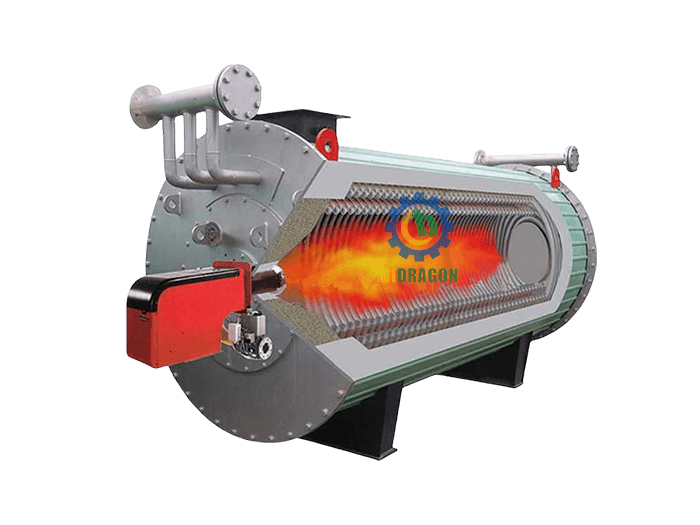

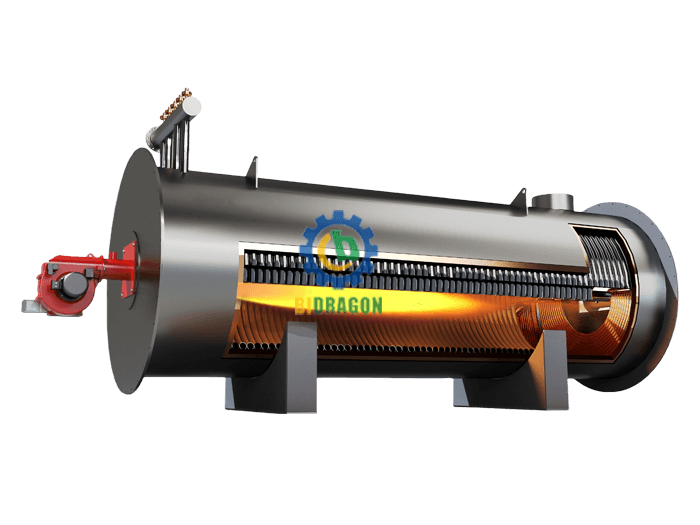

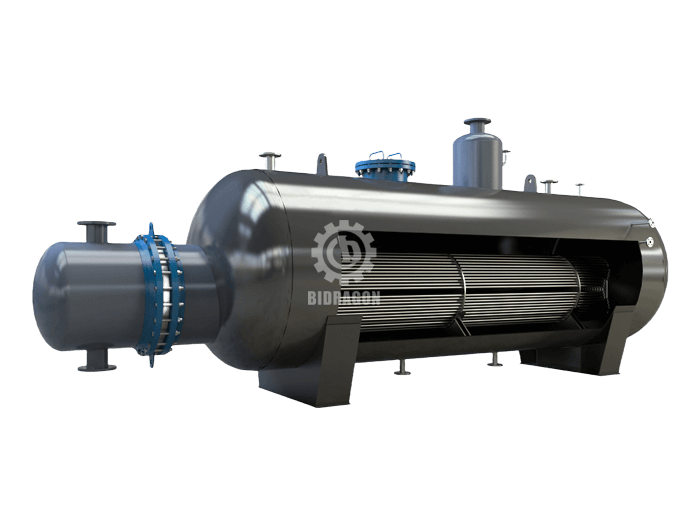

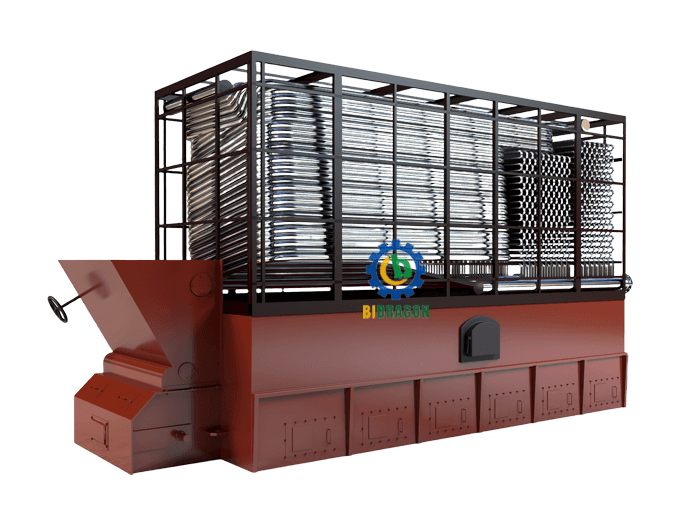

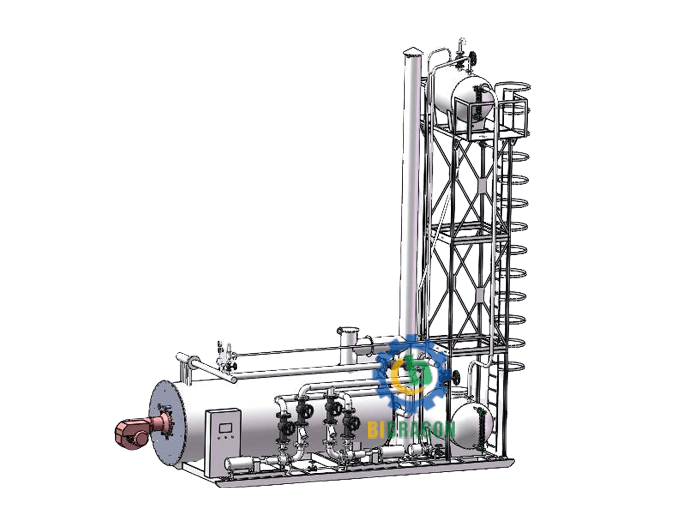

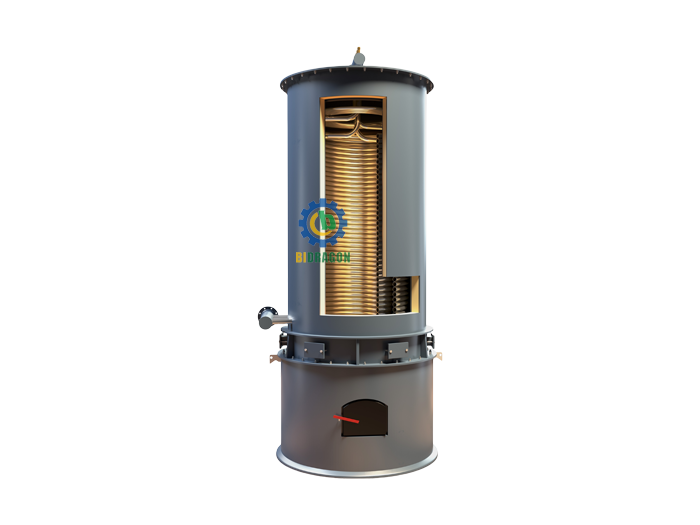

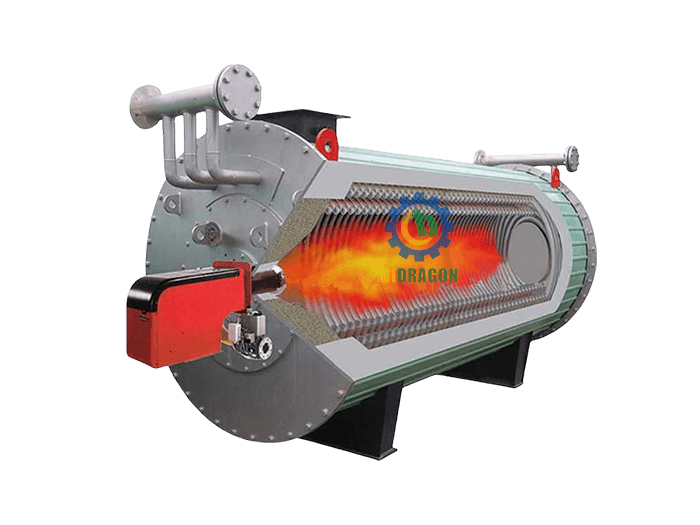

A thermal oil boiler, also often called a heat transfer medium or organic heat carrier boiler, is an industrial heating device that uses thermal oil as a heat transfer medium. It generates heat through fuel combustion or electrical energy conversion, and then uses a circulation system to stably transfer heat to the equipment requiring it. Its core function is to replace traditional steam boilers, solving the heat transfer and temperature control needs in high-temperature heating scenarios. It is widely used in various industries, including chemical, textile, printing and dyeing, plastics, rubber, food processing, wood processing, and building materials.

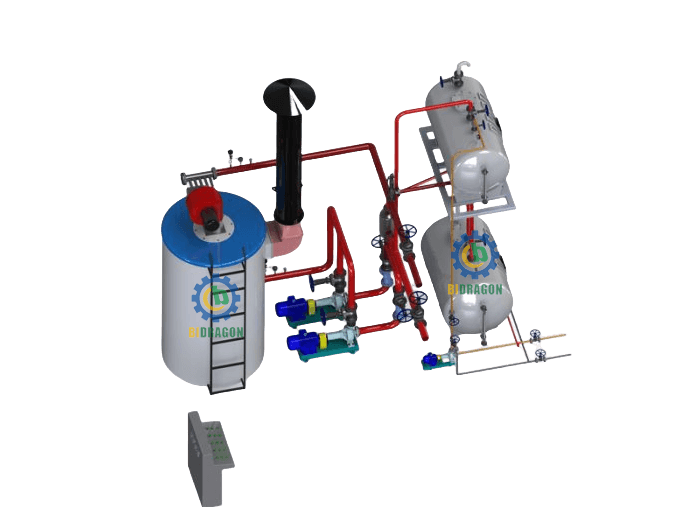

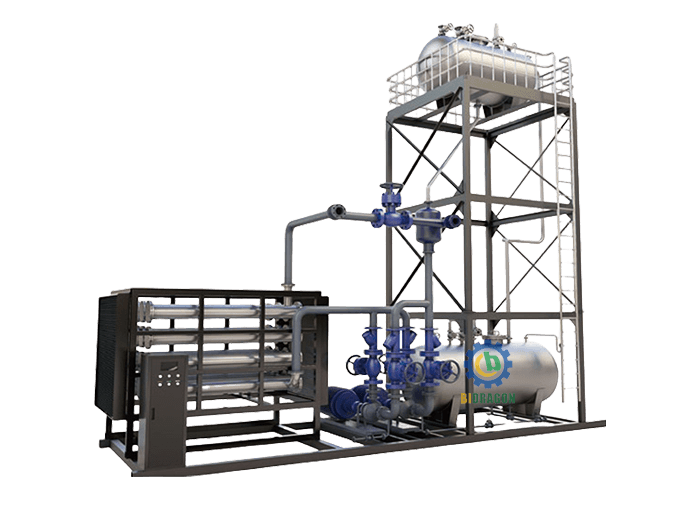

In terms of its operating principle, the operation process of a thermal oil boiler is clear and efficient. First, fuel (such as natural gas, diesel, or biomass pellets) burns in the furnace, or electric heating elements generate heat. The heat generated is directly transferred to the thermal oil in the boiler. Subsequently, driven by a circulation pump, the heated thermal oil continuously flows through a pre-configured pipeline system, delivering heat to heat-requiring equipment on the production line, such as reactors, dryers, molding machines, and molds. After the thermal oil has completed the heat transfer, its temperature drops and it is returned to the boiler through the return line for reheating. This creates a closed-loop cycle of "heating - heat transfer - return flow - reheating," ensuring a continuous supply of heat and efficient utilization.

Compared to traditional heating equipment, thermal oil boilers offer significant advantages, which is a key reason for their widespread popularity in the industrial sector. First, thermal oil boasts high temperature and low pressure. It can reach temperatures exceeding 300°C at ambient pressure (the specific temperature depends on the type and quality of the oil), eliminating the need for high pressures like steam boilers. This significantly reduces operational safety risks and the complex safety measures required for high-pressure equipment. Secondly, it offers precise temperature control. Thermal oil exhibits strong thermal stability, resulting in minimal temperature fluctuations during circulation. Combined with a precise temperature control system, it can maintain the temperature of heat-demanding equipment within a ±1°C range, meeting the stringent temperature requirements of production environments such as fine chemicals and food processing. Furthermore, it boasts high thermal efficiency. Thermal oil's high specific heat capacity and high heat transfer coefficient minimize heat loss during heat transfer. Unlike steam boilers, the equipment does not require regular condensate discharge, eliminating heat loss through condensate removal. Its thermal efficiency is typically 10%-20% higher than that of traditional steam boilers. Furthermore, thermal oil boilers offer simplified system maintenance, a long service life for the thermal oil (high-quality oil can provide 3-5 years of continuous use), and the equipment avoids the scaling issues associated with steam boilers, reducing the maintenance workload and costs associated with regular descaling.

Thermal oil heaters can be categorized into various types based on their heating methods. Common types include oil-fired, gas-fired, electric-heated, and biomass-fired. Oil-fired and gas-fired thermal oil heaters are suitable for medium- to large-scale factories with ample fuel supplies and high heating demands. Electric-heated thermal oil heaters, due to their lack of open flames, pollution-free operation, and higher temperature control precision, are suitable for laboratories or small production lines with strict environmental requirements and relatively low heating capacity. Biomass-fired thermal oil heaters, fueled by renewable biomass such as straw and sawdust, align with green environmental trends and are increasingly used in regions prioritizing sustainable development.

In practical applications, the selection of a thermal oil heater should be carefully considered based on specific production requirements, fuel costs, and environmental standards. To ensure long-term stable operation, the thermal oil should be regularly inspected and replaced, and components such as the circulation piping and temperature control system should be maintained to avoid safety hazards and reduced heating efficiency caused by thermal oil aging, pipe blockages, or temperature control failure.

With their core advantages of high temperature, low pressure, precise temperature control, and high thermal efficiency, thermal oil heaters meet the needs of many industries for stable and efficient heating. They are widely used in industrial production and processing scenarios. The following describes their main applicable industries and specific application scenarios:

The chemical and petrochemical industries are one of the core application areas for thermal oil heaters. A large number of production processes in this industry require continuous and precise high-temperature heating, and the characteristics of thermal oil heaters perfectly match these requirements. In actual production, they are often used to heat reactors for resin synthesis (such as epoxy resin and phenolic resin). Stable heat transfer ensures uniform polymerization reactions and prevents temperature fluctuations that affect product viscosity and performance. They are also used in the refining of lubricants, thermal oils, and other oil products. Precise temperature control enables distillation, fractionation, and purification. Furthermore, in the production of chemical fiber raw materials (such as caprolactam and polyester chips), thermal oil heaters provide constant heat for raw material preheating and chemical reactions, ensuring the quality of raw materials for subsequent spinning.

The molding and processing stages of the plastics and rubber industry are highly temperature-sensitive. Thermal oil heaters can provide a stable heat source for various equipment, improving product quality. In the plastics industry, they are commonly used to heat plastic extruders and injection molding machines. By uniformly heating the barrel and mold, they ensure that the plastic particles are fully melted and flow, avoiding carbonization caused by localized overheating or incomplete molding caused by underheating. In the production of plastic film, pipes, and sheets, they also provide heat for drawing and shaping equipment to ensure uniform product thickness and a smooth appearance. In the rubber industry, they are primarily used to heat rubber vulcanizers. By precisely controlling the vulcanization temperature and time, they ensure that the rubber raw materials are fully cross-linked and cured, improving the elasticity and wear resistance of rubber products (such as tires, seals, and hoses).

The dyeing, finishing, and shaping processes in the textile and printing and dyeing industries require extremely high temperature stability. Thermal oil heaters can meet the processing requirements of different fabrics, improving dyeing uniformity and fabric texture. In the dyeing and printing process, it is commonly used to heat dyeing and printing machines. By maintaining a constant temperature, it ensures that the dye is fully dissolved and evenly adheres to the fabric fibers, preventing color variations caused by temperature differences. In the textile setting process, it provides a heat source for heat setting machines. Through precise temperature control, fabrics (such as cotton, chemical fibers, and blended fabrics) are evenly set at high temperatures, minimizing shrinkage after subsequent washing while enhancing the fabric's crispness and gloss. Furthermore, in non-woven fabric production, it is also used to heat non-woven hot rolling mills, achieving thermal bonding and forming of the fibers.

The food processing industry places strict demands on the safety and temperature control accuracy of heating equipment. Thermal oil furnaces are essential heating equipment due to their lack of open flames, precise temperature control, and lack of direct contact with food. In the baking industry, thermal oil heaters are commonly used to heat tunnel ovens in biscuit and bread production lines. By evenly distributing heat, they ensure a uniform surface color and thoroughly cooked interior, preventing burnt areas. In candy and chocolate production, they provide stable heat to sugar boilers and chocolate melting vats, controlling the melting and cooking temperatures of the sugar, ensuring a soft and glutinous texture for the candies and a smooth and smooth texture for the chocolate. Furthermore, in fruit and vegetable dehydration and meat processing (such as sausage drying), thermal oil heaters provide heat for drying equipment, enabling low-temperature, slow drying, preserving the nutrients and flavor of the food while preventing high temperatures from damaging its ingredients.

The drying and modification processes in the wood processing industry require gentle and continuous heating. Thermal oil heaters prevent cracking and deformation of the wood due to sudden temperature changes, thereby improving the quality of the wood processed. In the wood drying process, thermal oil furnaces are often used to heat wood kilns. By circulating hot air, they transfer heat and slowly reduce the wood's moisture content (from an initial 30%-50% to 10%-15%), ensuring even evaporation of moisture within the wood and reducing warping and cracking after drying. In wood modification (such as wood preservation and flame retardant treatment), thermal oil furnaces provide heat to the modification tanks, allowing preservatives and flame retardants to fully penetrate the wood, improving its corrosion and fire resistance and extending its service life. Furthermore, in the production of artificial boards (such as plywood and fiberboard), they are also used to heat hot presses, bonding wood chips and fibers through high temperature and high pressure to ensure the strength and smoothness of the boards.

The high-temperature firing and molding processes in the building materials industry require large amounts of stable heat. Thermal oil furnaces can adapt to the production needs of different building materials, reducing energy consumption while ensuring product quality. In tile and ceramic production, thermal oil heaters are often used in the preheating of ceramic bodies. By gradually heating the bodies, moisture is slowly released, preventing cracking caused by rapid evaporation during subsequent high-temperature firing. In gypsum board production, they provide heat to the gypsum drying line, quickly and evenly drying the gypsum core, shortening production cycles while ensuring thorough drying of the gypsum board, enhancing moisture resistance and strength. Furthermore, in the production of insulation materials (such as rock wool and glass wool), thermal oil heaters provide auxiliary heating for the raw material melting equipment, working in conjunction with the main heating system to fully melt the raw materials and ensure fiber fineness and thermal insulation performance.

The pharmaceutical and fine chemical industries place extremely high demands on production environment cleanliness and temperature accuracy. The pollution-free and precise temperature control characteristics of thermal oil heaters meet these stringent requirements. In the pharmaceutical industry, thermal oil heaters are commonly used to heat reactors for the synthesis of pharmaceuticals (such as antibiotics and vitamins). Precisely controlling reaction temperatures ensures selectivity and conversion rates during synthesis reactions, preventing byproducts from affecting drug purity. In traditional Chinese medicine extraction, thermal oil heaters provide stable heat to the extraction tanks, enabling gentle extraction of active ingredients and minimizing damage to these ingredients caused by high temperatures. In the fine chemical industry, thermal oil heaters are commonly used in the production of flavors and fragrances, as well as food additives. Constant heat is used to control reactions such as esterification and oxidation in raw materials, ensuring product aroma, purity, and stability, and meeting industry quality standards.

The drying and laminating processes in the papermaking and printing industries require uniform heating. Thermal oil heaters can improve paper drying efficiency and print quality. In the papermaking industry, thermal oil heaters are commonly used to heat paper dryers. By uniformly heating the drying drum, thermal oil heaters rapidly dry out moisture from the paper, ensuring smoothness and strength, and preventing wrinkles caused by uneven drying. In cardboard production, thermal oil heaters also provide heat to laminators, enabling bonding and drying of multiple layers of cardboard, increasing thickness and hardness. The printing industry is mainly used for lamination and hot stamping processes of printed materials. The thermal oil furnace provides stable heat to the heating rollers of the laminating machine and hot stamping machine to ensure that the film fits tightly to the paper, the hot stamping pattern is clear and firm, and the texture and wear resistance of the printed materials are improved.

In most industrial applications, the conventional operating temperature range for thermal oil boilers is between 100°C and 320°C. This range meets over 80% of industrial heating needs and features mature thermal oil types and high system operational safety.

The medium-low temperature range (100°C-200°C) is primarily used in food processing (such as candy boiling and baking and drying), wood drying, and textile printing and dyeing. Thermal oils in this temperature range are typically basic mineral-based products, offering good fluidity and low cost, meeting heating requirements with low temperature requirements. Medium- and high-temperature range (200°C-320°C): Widely used in chemical synthesis (such as resin polymerization and oil refining), plastic and rubber extrusion molding, and pharmaceutical reactor heating. This requires the use of thermally stable mineral-based refined or synthetic heat transfer fluids to ensure they are less susceptible to cracking and coking at higher temperatures. The system also requires precise temperature control to prevent temperature fluctuations from affecting production quality.

For some industries with higher temperature requirements (such as high-end chemicals and specialty materials processing), thermal oil furnaces can operate at temperatures between 320°C and 400°C. However, this range places extremely stringent requirements on the thermal oil and system design:

Heat Transfer Fluid Type: Synthetic thermal oil (such as biphenyl-biphenyl ether mixtures or alkylbenzenes) must be used. These fluids have high thermal decomposition temperatures and strong oxidation resistance, enabling long-term stable operation at high temperatures and preventing system blockages or safety hazards caused by oil degradation.

System Design: High-pressure sealing structures, high-temperature-resistant piping (such as stainless steel), and high-efficiency heat exchange components must be utilized. A comprehensive degassing system (to remove air from the system and prevent oil oxidation) and an over-temperature protection system must also be equipped to ensure safety and stability during high-temperature operation.

Typical Applications: These applications are often used in specialty resin synthesis, high-end film production, and auxiliary heating for metal heat treatment. Precise temperature control is required based on the specific process, with a temperature differential typically required to be within ±2°C.

In a limited number of scenarios, thermal oil heaters can also be used for low-temperature heating in the 50°C-100°C range. These are primarily suitable for temperature-sensitive processes requiring gentle heating.

Applications include cosmetic raw material mixing, ink preparation, and low-temperature drying of biological products. In this temperature range, thermal oil with good low-temperature fluidity is required to prevent solidification and pipe clogging at low temperatures. The system must also be equipped with a low-temperature circulation pump and precise low-temperature temperature control modules to ensure uniform heat transfer and prevent localized low temperatures that affect production efficiency.

Advantages: Compared to traditional electric or steam heating, thermal oil heaters offer higher temperature control accuracy (temperature differentials can be controlled to within ±1°C) and minimize heat loss, reducing energy costs. Key Factors Affecting the Operating Temperature Range

Thermal stability of thermal oil: This is the key factor in determining the upper temperature limit. The "maximum allowable operating temperature" of thermal oil (usually specified by the manufacturer) directly limits the operating temperature of the furnace. Exceeding this temperature will cause the oil to rapidly decompose and form carbon deposits, which not only affects heat transfer efficiency but may also cause pipe blockage or fire risks.

System Pressure: Thermal oil furnaces operate on the "high temperature, low pressure" principle. The lower the system pressure, the higher the allowable operating temperature (and vice versa). Conventional open systems operate at near-atmospheric pressure, with temperatures typically below 320°C. Closed high-pressure systems can slightly increase the temperature by increasing the pressure, but this must strictly match the pressure tolerance of the thermal oil.

Temperature Control and Safety Devices: A high-quality temperature control system (such as PLC intelligent temperature control and multi-point temperature monitoring) can precisely control the operating temperature to prevent overheating or temperature fluctuations. Furthermore, safety devices such as overtemperature alarms, pressure protection, and oil shut-off protection will indirectly influence the actual operating temperature range (requires safety redundancy to avoid reaching dangerous thresholds).

Key Technical Parameters to Consider When Selecting a Thermal Oil Boiler

When selecting a thermal oil boiler, the matching of technical parameters directly determines whether the equipment can meet production needs, ensure operational safety, and control energy costs. Focus on the following key parameters:

Rated Heat Power

This is a core indicator of the heating capacity of a thermal oil boiler, typically measured in kilowatts (kW) or megawatts (MW). The selection must be based on the total heat load of the production process. Calculate the total hourly heat consumption of all heating equipment (such as reactors, dryers, and heat exchangers), and allow for a 10%-20% margin to avoid shortening the equipment's lifespan due to long-term full-load operation. For example, heating a 10m³ reactor in the chemical industry typically requires a rated heat power of 200-300kW. If multiple devices are being heated simultaneously, the total heat load must be calculated before selecting a model.

Thermal Efficiency

This indicates the efficiency of a hot oil boiler in converting fuel (such as natural gas, diesel, or electricity) energy into heat for the thermal oil. This percentage directly impacts operating energy costs. Conventional oil/gas-fired thermal oil boilers typically have a thermal efficiency of 85%-92%, while high-efficiency condensing models can reach over 95%. Electric-heated thermal oil boilers have a thermal efficiency approaching 100% (but with higher operating costs). When selecting a thermal oil boiler, consider a comprehensive assessment of local fuel prices. For example, in areas with low natural gas prices, high-efficiency condensing gas-fired models are preferred, as they can significantly reduce energy costs in the long term.

Rated Operating Temperature

This indicates the upper limit of the stable operating temperature of the hot oil boiler design. This must match the required temperature of the production process and the maximum allowable operating temperature of the thermal oil. The rated operating temperature of the equipment must be 5-10°C higher than the required process temperature (to allow for safety margins) and must not exceed the maximum allowable temperature of the thermal oil used (otherwise, it may cause oil cracking and coking). For example, if the process requires heating at 280°C, a model with a rated operating temperature ≥ 290°C should be selected, along with a thermal oil with a maximum allowable temperature ≥ 300°C.

Working Pressure

Thermal oil boilers operate in a "high temperature, low pressure" mode, and their operating pressure is typically low (close to atmospheric pressure for open systems, and 0.3-1.0 MPa for closed systems). However, two key pressure indicators should be considered: the "design pressure" (the maximum pressure the equipment can withstand, which must be 1.2-1.5 times higher than the operating pressure for safety); and the "circulating system pressure" (provided by the circulating pump and ensuring smooth circulation of the thermal oil within the pipeline to avoid local overheating). The system pressure is typically required to be ≥ 0.2 MPa to prevent oil vaporization.

Compatible Heat Transfer Oil Types

Different models are designed to be compatible with different heat transfer oil types (e.g., mineral, synthetic, alkylbenzene, etc.). The choice should be based on the process temperature requirements: mineral-based heat transfer oil is suitable for medium- and low-temperature applications (≤250°C), while preformed heat transfer oil is suitable for high-temperature applications (≥250°C). Furthermore, the equipment's piping material and seal temperature resistance must be compatible with the heat transfer oil type. For example, synthetic heat transfer oil may corrode ordinary rubber seals, so oil- and high-temperature-resistant seals such as fluororubber should be selected.

Circulating Oil Volume

This refers to the amount of heat transfer oil passing through the furnace heating chamber per unit time, measured in cubic meters per hour (m³/h). It directly impacts heat transfer efficiency and temperature uniformity. The circulating oil volume must meet the requirement of a "thermal oil flow rate within the furnace tubes ≥ 1.5 m/s" (to avoid localized oil overheating and coking due to low flow rates). It must also match the flow rate of the circulating pump. For example, a model with a rated thermal power of 300 kW typically requires a circulating pump with a circulating oil flow rate of ≥ 15 m³/h to ensure timely heat transfer to the heat-consuming equipment.

Safety Protection Configuration

Safety parameters are crucial for model selection. Ensure the equipment is equipped with the following key protection devices:

Overtemperature Protection: Automatically shuts off the fuel supply or power supply when the thermal oil temperature exceeds the rated value.

Overpressure Protection: Automatically releases pressure and issues an alarm when system pressure exceeds a certain level.

Oil Cutoff Protection: Immediately stops heating if the circulating pump fails and the oil level is insufficient, preventing the furnace tubes from drying out.

Flame Failure Protection (Oil/Gas Models): Automatically closes the fuel valve if the flame fails, preventing gas leaks.

Temperature Control Precision

This refers to the control error of the thermal oil temperature by the equipment, measured in ±°C, which directly impacts product quality. Conventional industrial applications require a temperature control accuracy of ≤±2°C, while high-precision applications (such as pharmaceutical synthesis and electronic material processing) require ≤±1°C. Select a model equipped with a PLC intelligent temperature control system and multiple temperature monitoring sensors to ensure stable, unfluctuating temperatures.

Fuel Type

Thermal oil boilers can be fueled by gas (natural gas, liquefied petroleum gas), fuel oil (diesel, heavy oil), electric heating, and biomass. The choice should be based on the site's fuel supply. Where there is a stable natural gas supply, gas-fired models are preferred (clean and low operating costs). Where there is no gas supply but sufficient electricity, electric heating models are preferred (easy installation and precise temperature control). Where there is a large amount of industrial waste, biomass models can be considered (environmentally friendly and low cost). Also, pay attention to fuel consumption (e.g., natural gas consumption in m³/h for gas-fired models, which must match the on-site gas pipeline flow). Dimensions & Installation Requirements

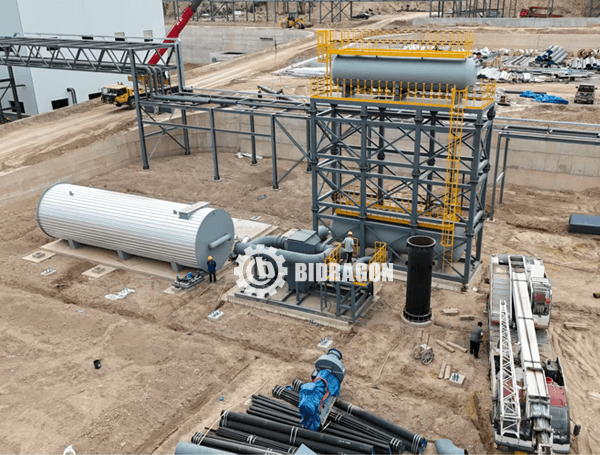

The equipment's length, width, and height dimensions must be determined based on the workshop space to avoid installation difficulties. Also, pay attention to installation-related parameters, such as the exhaust port diameter (which must match the exhaust duct to ensure smooth exhaust), power supply voltage (e.g., 380V/3Phase or 220V/1Phase, which must match the workshop power supply), and load-bearing requirements (the total weight of the equipment during operation; the workshop floor's load-bearing capacity must be confirmed).

Key Points for Daily Maintenance and Care of Thermal Oil Boilers

Daily maintenance and care of thermal oil boilers is crucial to ensuring safe and stable operation, extending service life, and reducing the risk of failure. This process should focus on four key areas: thermal oil management, component inspection, system cleaning, and safety device calibration. Specific key points are as follows:

Regular Monitoring and Management to Prevent Oil Deterioration

Thermal oil is the core medium for heat transfer, and its performance directly impacts the efficiency and safety of the equipment. The following maintenance items require special attention:

Regular Oil Quality Testing: Samples should be taken every 3-6 months to test key thermal oil properties, including acid value, viscosity, flash point, and carbon residue. An elevated acid value (typically exceeding 0.5 mgKOH/g) can corrode equipment piping, necessitating the timely addition of antioxidants or partial oil replacement. Abnormal viscosity changes (deviating by more than 20% from the initial value) may indicate oil cracking or contamination, requiring investigation into excessive heating temperatures. Excessive carbon residue (over 1.5%) can lead to coking of furnace tubes, necessitating shutdown, cleaning, or oil replacement. Oil Level Control and Refilling Rules: Check the thermal oil level in the expansion tank daily to ensure it is between the "minimum" and "maximum" marks. A low oil level can cause air to enter the circulation system, leading to localized overheating; a high oil level can cause overflow during heating. When refilling, use the same type and brand of thermal oil as the original oil (mixing different oil types can cause chemical reactions and degrade performance). After refilling, allow the unit to circulate for 30 minutes to ensure thorough mixing of the new and old oils.

Preventing Oil Contamination: When refueling, filter impurities through an oil filter to prevent dust, moisture, and metal debris from entering the system. Regularly check the seal of the breather valve on top of the expansion tank to prevent rainwater and impurities from entering. If a leak occurs in the system, clean the leak area after repair to prevent impurities from entering the tank with the refilled oil.

Daily Inspection and Regular Maintenance to Ensure Stable Operation

Heating System (Oil/Gas Burners, Electric Heating Tubes)

Oil/Gas Burners: Check the nozzles daily for blockage (if the flame is yellow and irregular, it may be due to nozzle coking). Disassemble and clean the nozzles weekly. Clean carbon deposits inside the burner monthly (excessive carbon deposits will reduce thermal efficiency). Check the gap between the ignition electrodes (usually 3-5mm; a larger gap can cause ignition failure). Check the gas valve train for tightness quarterly, grease the joints with soapy water, and replace the gaskets if bubbling occurs.

Electric Heating Tubes: Inspect the surface of the heating tubes daily for coking (coking can prevent heat transfer and burn the heater tubes). If coking is detected, shut down the unit and clean with a dedicated decoking agent. Test the insulation resistance of the heating tubes every three months (using a megohmmeter, the insulation resistance must be ≥1MΩ to prevent leakage). Replace damaged or deformed heating tubes immediately to prevent thermal oil from seeping into the circuit and causing a short circuit.

Circulation System (Circulation Pump, Pipes, Valves)

Circulation Pump: Check the pump's operating sound daily (normally, there should be no unusual noise. Any unusual noise may indicate bearing wear). Check the pump casing temperature (no more than 70°C; if the temperature is too high, check the lubricant). Check the pump seals weekly for leaks (if there is oil contamination on the shaft seal, replace the seal ring). Replace the circulation pump bearing lubricant every six months (use high-temperature-resistant 32# or 46# mechanical oil) and clean any impurities inside the pump.

Pipes and Valves: Check pipe connections and valve flanges daily for oil leaks (if leaks are detected, tighten the bolts or replace the gaskets). Open the drain valve on the pipe monthly, drain a small amount of thermal oil, and clean any sediment inside the pipe. Check the valve opening and closing motions quarterly. If the valve is stuck, remove the valve core, clean it with kerosene, and then apply high-temperature grease.

Furnace Tube Decoking: After a thermal oil boiler has been operating for one to two years, or if "the outlet oil temperature is normal but the heat-consuming equipment temperature is insufficient" or "the exhaust gas temperature is abnormally high (exceeding 250°C)" occurs, the furnace tubes must be shut down to clean the coke. This can be done by chemical decoking (injecting a special decoking agent, circulating the reaction, and then removing the residue) or mechanical decoking (using a high-pressure water gun or a special scraper, taking care to avoid scratching the inner tube walls). After decoking, flush the system with new thermal oil and refill it.

Heat Exchanger and Heat Dissipation Component Cleaning: If the equipment is equipped with an air heat exchanger (such as the waste heat recovery heat exchanger in a gas-fired model), clean the heat exchanger surface of dust and oil every two months (using compressed air or a neutral detergent). The exhaust duct should be inspected quarterly. If there is dust accumulation on the inner wall, clean it with a dust brush to ensure smooth exhaust. Excessive exhaust resistance can reduce thermal efficiency and increase energy consumption.

Safety devices are key to preventing accidents and must be rigorously calibrated periodically to ensure they are effective and sensitive:

Temperature Protection Devices: Simulate over-temperature scenarios monthly to test whether the over-temperature alarm triggers and the heating system automatically shuts down. Calibrate temperature sensors (such as thermocouples and RTDs) using a standard thermometer every six months to ensure a temperature display error of ≤±2°C.

Pressure Protection Devices: Check the safety valve seal weekly for integrity. Have the safety valve calibrated annually by a professional to ensure the opening pressure meets the design value, typically 1.2 times the operating pressure. Check the pressure gauge pointer monthly for zero readings and calibrate the pressure gauge every six months (with an error of within ±0.4%).

Oil and Flameout Protection: Test the circulation pump's "oil outage protection" function monthly by manually shutting off the circulation pump and observing whether the heating system immediately stops. For oil/gas models, test the "flameout protection" function every two weeks by manually shutting off the fuel supply during operation and observing whether the burner immediately shuts down and the gas valve is sealed to prevent gas leaks.

Daily Records and Ledgers: Establish a maintenance log to record equipment operating parameters (inlet and outlet oil temperatures, pressures, circulation pump current, and fuel consumption) daily. Monthly compile oil test reports and component maintenance status to facilitate tracking of equipment status and proactively detect abnormalities (such as sudden oil temperature rises or pressure fluctuations).

Post-Shutdown Maintenance: If the equipment is shut down for an extended period (more than one month), drain all thermal oil from the system into the oil storage tank and clean any impurities. Close all valves and apply anti-rust oil to pipes and valve joints. Regularly (every two weeks) start the circulation pump for 10 minutes to prevent bearing rust. When the ambient humidity is high, fill the expansion tank with nitrogen to prevent oil oxidation.

Operator Training: Maintenance personnel must be familiar with the equipment structure and safety procedures to avoid operating inappropriately (such as operating at excessive temperatures or starting the unit without checking the oil level). Regular emergency drills (such as handling oil leaks and overheating incidents) should be conducted to ensure timely response to emergencies.

Common Thermal Oil Boiler Operational Failures and Solutions

During thermal oil boiler operation, failures are often related to the thermal oil performance, circulation system, heating system, and safety devices. Failure to address these issues promptly can lead to decreased efficiency, equipment damage, and even accidents. The following are the symptoms, causes, and targeted solutions for common failures, helping to quickly troubleshoot and restore operations:

Common Symptoms

The circulating pump outlet pressure is too low (less than 80% of the design value), or the pressure gauge pointer fluctuates dramatically;

The temperature of the heat-consuming equipment remains low, while the outlet oil temperature of the thermal oil boiler has reached the set value;

The circulating pump is noisy and the pump body is hot (over 70°C).

Core Causes

Air in the system: Failure to completely remove air during thermal oil replenishment, or a low expansion tank oil level, allowing air to enter;

Circulating pump failure: Impeller wear, blockage, bearing damage, or motor phase loss;

Pipeline Blockage: Carbon residue and impurities from thermal oil degradation deposit in the pipeline or heat exchanger, reducing the flow area.

Solution

Clear the system of air: Turn off the heating system, turn on the circulation pump, and slowly open the "exhaust valve" on the pipe (operating from the highest position to the lowest position) until bubble-free thermal oil flows out of the exhaust valve, then close the exhaust valve. At the same time, replenish the thermal oil to the "highest" mark on the expansion tank to prevent further air intake.

Repairing the circulation pump: If the pump is noisy or overheating, first shut down the machine for inspection. Disassemble the pump body and clean any impeller debris and carbon residue. If the impeller is severely worn (deformed or chipped blades), replace it with a similar model. Check the motor wiring to rule out phase loss. If the bearings are worn, replace high-temperature bearings (such as type 6308) and add 32# mechanical oil.

Clearing pipe blockages: First, check the carbon residue in the thermal oil. If it exceeds 1.5%, partially replace the oil. Then, shut down the machine, disassemble the pipe valves and heat exchanger, and clean the impeller with a high-pressure water jet (control the pressure at Flushing internal deposits (0.8-1.2MPa) or using a dedicated pipe dredge. For stubborn blockages, inject a chemical cleaner (such as a neutral descaling agent), soak for 4-6 hours, then flush to ensure the pipes are unobstructed.

Common Symptoms

The temperature controller displays the oil temperature exceeding the set point (e.g., the designed maximum temperature is 300°C but the actual temperature reaches 320°C), triggering the over-temperature alarm.

The thermal oil becomes darker (black-brown) and has a pungent odor (gases produced by cracking).

The furnace tube surface becomes partially red (coking prevents heat transfer).

Core Causes

Circulation system failure: The circulation pump is stopped or the flow rate is insufficient, preventing the thermal oil from removing heat from the furnace tubes.

Heating system out of control: The burner (oil/gas) valve is stuck, causing continuous oil/gas supply.

The electric heating element thermostat is damaged and cannot be shut off.

The thermal oil deteriorates: The oil is operated at excessive temperatures for a long time, cracking to produce low-boiling products, lowering the flash point, and reducing heat dissipation efficiency.

Solution

Emergency Action: Immediately press the "Emergency Stop" button to shut off the power/fuel supply to the heating system. Keep the circulation pump running (if the pump is functioning properly) to allow the cool oil to continue removing heat from the furnace tubes to prevent burns. If the circulation pump fails, manually activate the backup pump.

Troubleshoot the heating system: For oil/gas models, disassemble the burner valve, clean any impurities from the valve core, and check that the solenoid valve closes properly. For electric models, replace the damaged thermostat and use a multimeter to check the heating tube wiring to ensure that the power is shut off in the event of an overheat.

Treating Deteriorated Oil: Take samples and test the thermal oil for acidity, flash point, and carbon residue. If the acidity is greater than 0.5 mgKOH/g or the flash point has dropped by more than 15% of its initial value, replace 50%-80% of the oil with new oil (retain some old oil to avoid compatibility issues). Before replacement, clean any carbon residue from the tank and pipes. Add the new oil and circulate for 30 minutes to ensure even mixing.

Common Symptoms

When the burner starts, there is no spark from the ignition electrode, or there is a spark but the fuel cannot be ignited.

During combustion, the flame fluctuates, is yellow (normally blue), and is accompanied by black smoke.

The burner frequently stalls, and the fault light illuminates.

Core Causes

Fuel supply issues: Low fuel tank level, clogged fuel pipe, or insufficient fuel pump pressure for oil-fired engines; low gas pressure (less than 0.02 MPa) or a clogged gas valve for gas-fired engines.

Ignition system failure: Excessive ignition electrode gap (over 5 mm) or carbon deposits, or aging of the high-voltage ignition wire.

Insufficient air supply: A malfunctioning fan results in insufficient air volume, or a clogged air filter prevents adequate fuel combustion.

Solution

Ensure fuel supply: For oil-fired engines, fill the tank with diesel fuel to 2/3 of its capacity. Remove the fuel line filter to clean impurities. Check the fuel pump pressure (normally 0.2-0.4 MPa). If pressure is insufficient, replace the fuel pump. For gas-fired engines, contact the gas supplier to adjust the pressure. Remove the gas valve core and clean it with kerosene to remove oil contamination.

Repair the ignition system: After powering off, sand the ignition electrode with fine sandpaper to remove carbon deposits and adjust the electrode gap to 3-5 mm. Replace aged high-voltage ignition wire (choose wire with a temperature resistance of 150°C or above).

Optimize air supply: Check the fan's operating status. If the fan is not rotating, replace the motor. Remove the air filter and use compressed air to remove dust (or replace the filter) to ensure smooth air circulation. If the flame remains yellow, increase the fan damper to increase air flow until the flame turns blue.

Common Symptoms

Oil stains appear on the ground around the equipment, and there is a slight burnt smell of thermal oil.

The oil level in the expansion tank drops rapidly, and continues to drop even after refilling.

In severe cases, the leaking thermal oil may smoke when exposed to high temperatures, or even cause a fire.

Core Causes

Seal aging: Gaskets (rings) in pipe flanges and valve stuffing boxes deteriorate due to long-term high-temperature conditions, losing their elasticity.

Component Damage: Pipeline welds crack due to vibration, valve core wear, and circulating pump shaft seal damage.

Installation Issues: Uneven tightening of flange bolts leads to unbalanced force on the sealing surface, resulting in gaps.

Solution

Emergency Action: If the leak is small, first close the valves near the leak (disconnect the oil supply in the area), then clean up the oil on the floor after shutting down the machine. If the leak is large and there is a risk of smoke, immediately shut down the machine and disconnect the power supply. Use a dry powder fire extinguisher (do not use water) to prevent fire, and evacuate personnel.

Replace Seals: Disassemble the flanges and valves at the leaking site, remove any worn gaskets (rings), and replace them with high-temperature-resistant seals (such as fluororubber gaskets or graphite packing, with a temperature resistance of 300°C or higher). Apply high-temperature sealant to the sealing surfaces during installation to enhance the seal.

Repair Damaged Components: Inspect pipe welds. If cracks are present, repair them with argon arc welding (after repairing, perform a pressure test at 1.5 times the operating pressure, maintaining pressure for 30 minutes without leakage). Replace valves with the same model if the valve core is worn. If the circulating pump shaft seal is damaged, replace the seal assembly. During installation, ensure that the sealing surfaces are aligned to prevent misalignment.

Common Symptoms

The oil temperature exceeds the set value, the overtemperature alarm does not sound, and the heating system continues to operate;

The system pressure exceeds the safety valve opening pressure (e.g., operating pressure 1.0 MPa, safety valve design opening pressure 1.2 MPa), and the safety valve does not trip;

The pressure gauge needle does not move, or the displayed value deviates significantly from the actual pressure (e.g., actual pressure 0.8 MPa, gauge indicates 0.5 MPa).

Core Causes

Temperature/Pressure Sensor Failure: The sensor (thermocouple, pressure transmitter) is aging, or the wiring is loose or damp;

Stuck Safety Valve: Impurities inside the safety valve or the spring is aging, preventing it from opening properly;

Damaged Pressure Gauge: The spring tube inside the gauge is deformed, or the needle is stuck, resulting in loss of measurement accuracy.

Solution

Sensor Repair: Disconnect the power supply and check that the sensor wiring is secure. Use a multimeter to test the signal output (for example, a thermocouple should normally output 4-20mA). If the sensor is aging, replace it with a similar model (e.g., a K-type thermocouple with a temperature resistance of ≥400°C). After installation, calibrate it with a standard thermometer/pressure gauge to ensure an error of ≤±2°C/±0.05MPa.

Safety Valve Verification: After shutting down, disassemble the safety valve and clean any impurities and carbon residue from the valve seat. Use dedicated calibration equipment to test the opening pressure. If the spring is aging, replace it. After passing the calibration, reseal the valve to ensure it will trip in the next overpressure event.

Pressure Gauge Replacement: Remove the damaged pressure gauge and replace it with a high-temperature-resistant pressure gauge with an accuracy grade of ≥1.6 (a range of 1.5-2 times the working pressure). During installation, ensure the connections are sealed. Open the valve and slowly increase the pressure to verify that the needle moves smoothly and without any sticking.