Industrial boilers, as critical power equipment in industrial production, are subject to long-term, harsh operating environments characterized by high temperatures and high pressures, and are also subject to continuous corrosion from media such as flue gas and water vapor. Under these operating conditions, various damages inevitably occur to boiler tubes, and tube damage is one of the main causes of boiler failure. These failures not only disrupt normal industrial production and cause economic losses, but can also lead to safety incidents and threaten personnel safety.

Retubing, a crucial boiler maintenance technique, effectively resolves tube damage, extends the boiler's service life, and restores its original performance. Therefore, it is essential for industrial boiler maintenance.

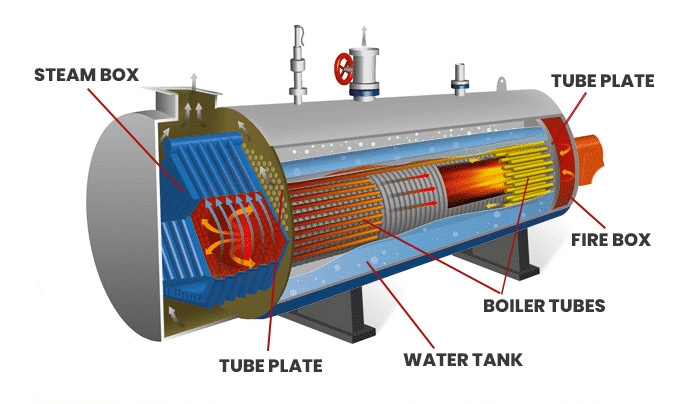

Boiler retubing involves a comprehensive inspection of the boiler's internal heating surface tubes, including the flue and water tubes, removing damaged tubes and replacing them with new ones. This process requires specialized technology and equipment to ensure safe and efficient operation of the retubated boiler.

The primary purpose of retubing is to restore heat transfer efficiency. Damaged tubes can reduce heat transfer performance due to corrosion and scaling, affecting the boiler's thermal efficiency. Replacing new tubes can effectively improve this situation. Secondly, replacing tubes can extend equipment life by preventing further failures of other components caused by tube damage, thereby extending the service life of the entire boiler system. Finally, and most importantly, replacing tubes improves safety, eliminating potential safety hazards associated with tube damage and ensuring safe boiler operation.

The core concept of boiler tube replacement is to fundamentally address tube damage issues by replacing new tubes, combined with optimized water treatment processes, to restore boiler performance to near-new condition. New tubes offer excellent heat transfer performance and structural strength, while optimized water treatment reduces corrosion, scaling, and other damage to the tubes, thereby maintaining efficient and safe boiler operation.

From a cost perspective, tube replacement is relatively inexpensive. Replacing an entire boiler requires a significant investment in new equipment, installation, and commissioning, while tube replacement only involves the cost of tubes, related accessories, and labor, making it a more economical option for many companies.

In terms of time, tube replacement typically takes less time. Replacing an entire boiler requires a complex process, including equipment procurement, removal of old equipment, and installation of new equipment. This process is time-consuming and can significantly impact production. However, tube replacement can be completed in a shorter timeframe, enabling faster boiler operation and minimizing production interruptions.

From a feasibility analysis, tube replacement is a viable maintenance option for some relatively recent boilers whose other components are in good condition. However, if the boiler is severely aged and multiple components are experiencing serious failures, replacing the entire boiler may be a more appropriate option. However, in most cases, tube replacement offers significant cost and time savings for the company while maintaining boiler performance, making it more feasible.

Corrosion is a common cause of boiler tube damage. The main causes include the erosion of tube metal by substances such as dissolved oxygen and carbon dioxide in water, as well as acidic condensate. Dissolved oxygen reacts with metal, gradually damaging the tube surface. Carbon dioxide dissolves in water to form carbonic acid, lowering the water's pH and exacerbating corrosion. Acidic condensate directly chemically corrodes the tube. Corrosion manifests itself in various forms on tubes. Common forms include pitting, which creates pits on the tube surface; perforation, which, when corrosion reaches a certain level, can corrode through the tube, creating holes; and cracking, which weakens the metal and causes cracks under stress.

Scaling is primarily caused by the deposition of minerals such as calcium, magnesium, and silicon in hard water on the inner walls of tubes. When the boiler is running, the water heats up, reducing the solubility of these minerals. These minerals gradually precipitate and adhere to the inner walls of the tubes, forming scale.

Scaling is extremely harmful. First, it reduces heat transfer efficiency. Scale has a much lower thermal conductivity than metal, hindering heat transfer, reducing boiler efficiency and increasing fuel consumption. Second, scaling can cause metal overheating. Because heat cannot be transferred away quickly, the tube wall temperature rises, exceeding the metal's tolerance and weakening its strength. In severe cases, it can cause tube ruptures and serious safety incidents. 3.3 Caustic Embrittlement

Caustic embrittlement is typically caused by improper water treatment, resulting in high concentrations of alkali in boiler water. This alkali corrodes metals, causing them to become brittle. Under high temperature and high pressure, embrittled metals are prone to cracking, compromising the structural strength of the tubes.

The primary hazard of alkali embrittlement is tube cracking. Once cracks develop, they can cause leaks and other problems, seriously threatening the safe operation of the boiler.

The hydrostatic test is an important means of verifying the structural strength of boiler tubes. If a boiler tube fails the hydrostatic test, it indicates that its structural strength is insufficient to withstand the pressures of normal operation and requires immediate attention. Otherwise, serious safety hazards such as explosions may occur during operation.

Before tube replacement, a comprehensive inspection and diagnosis of the boiler tubes is required. First, perform a visual inspection to observe the tube surface for obvious signs of damage, such as corrosion, scaling, deformation, and cracks. Nondestructive testing (NDT) techniques, such as ultrasonic testing, radiographic testing, and magnetic particle testing, are then used to thoroughly inspect the interior and surface of the tubes for defects, determining the location, extent, and cause of damage, providing an accurate basis for subsequent tube replacement.

Based on the inspection and diagnosis results, tubes that are aged, corroded, or severely scaled are removed using specialized tools. During the removal process, care must be taken to avoid damage to other boiler components and to ensure safe removal. Removed old tubes must be properly disposed of to prevent environmental pollution.

New tubes must be custom-made according to boiler specifications, ensuring that their dimensions, materials, and other parameters match the boiler's requirements. Before installing the new tubes, the tube plates must be cleaned and repaired to remove dirt and corrosion products, and to repair any defects to ensure a secure connection between the new tubes and the tube plates. Tubeline installation primarily involves expansion and welding. For some specialized tubes, such as stay tubes, sealing welding is also required. Expansion mechanically creates a tight connection between the tube and the tube sheet, ensuring sealing and heat transfer. Welding, on the other hand, uses high temperatures to weld the tube and tube sheet together, further enhancing the strength and sealing of the connection.

After the tube replacement is complete, rigorous testing and certification are required. Initially, phased inspections are conducted, including visual inspections and non-destructive testing (NDT), to verify the installation quality of the new tubes and the sealing of the connections. A final hydrostatic test, typically at 1.5 times the design pressure, is then conducted to verify the structural strength and sealing performance of the tubes.

After all tests pass, relevant quality and safety documentation must be completed, including tube replacement process records, inspection reports, and certifications. These documents are crucial for the legal and safe operation of the boiler.

By replacing damaged tubes, problems such as reduced heat transfer efficiency caused by tube problems are eliminated, allowing the boiler to return to optimal operating efficiency and ensuring the steam or hot water supply required for industrial production.

Because the boiler's operating efficiency is restored, fuel consumption is reduced for the same amount of heat generated, thereby reducing the company's fuel costs. Furthermore, tube replacement reduces the failure rate of the boiler, reducing repair costs and downtime losses, further reducing operating costs.

Tube replacement eliminates safety hazards caused by tube damage, such as bursts and leaks, allowing the boiler to operate safely, ensuring production safety and the safety of personnel.

With the continuous updating of environmental protection and safety regulations, the operating requirements for industrial boilers are becoming increasingly stringent. Tube replacement can ensure that the boiler's performance and safety indicators meet the latest regulations and industry standards, avoiding penalties for non-compliance.

By replacing tubes, boiler service life is extended, allowing companies to postpone the need to replace the entire boiler, thereby deferring significant capital expenditures, saving the company money, and improving capital efficiency.

Steam boilers are critical power equipment in the manufacturing industry. After long-term, high-intensity operation, their tubes are susceptible to various damages. After years of operation, a steam boiler at an automobile manufacturer experienced decreased heat transfer efficiency and increased energy consumption. Inspection revealed severe scaling and corrosion in the tubes. A tube replacement overhaul replaced all damaged tubes and optimized the water treatment system. This significantly improved boiler efficiency, reduced fuel consumption by 15%, and significantly reduced operating costs.

The high-pressure section of a power plant boiler operates in an extremely harsh environment, subject to the dual effects of high temperature and high pressure. This makes the tubes susceptible to fatigue damage and corrosion. During an inspection, multiple cracks were discovered in the high-pressure section tubes of a boiler at a thermal power plant. If not addressed promptly, this could lead to a serious safety incident. The power plant used tube replacement technology to replace all damaged tubes in the high-pressure section. Testing confirmed that the boiler's safety performance was ensured, operating stably, and power generation efficiency was improved.

The water used in chemical industry boilers often contains high levels of corrosive substances, which can lead to frequent corrosion of tubes. Due to water quality issues, a chemical company's boilers suffered severe corrosion, requiring extensive maintenance every six months. To address this issue, the company replaced the boiler tubes with more corrosion-resistant tube materials and fully upgraded the water treatment system. After the replacement, the corrosion rate significantly slowed, extending the maintenance cycle to over two years, significantly reducing maintenance costs and production interruption time.

Boilers in the food processing industry require large quantities of steam for processes such as sterilization and cooking. Minerals in the water can easily form scale in the tubes. Severe scaling in the boilers of a food processing plant resulted in uneven heating, affecting product quality and significantly increasing energy consumption. By replacing the existing tubes, the scale in the existing tubes was removed and replaced with new ones. This restored the boiler's heating performance, improved product quality stability, and reduced fuel consumption by 10%.

The quality of boiler feedwater directly affects the lifespan of the tubes. Establishing a comprehensive feedwater treatment system is key to preventing tube damage. This system should include water softening, deaeration, and desalination processes to reduce the levels of calcium, magnesium, oxygen, and other substances in the water, thereby minimizing scaling and corrosion. Feedwater treatment equipment should also be regularly maintained and inspected to ensure proper operation and that feedwater quality meets boiler operating requirements.

Regular inspection and nondestructive testing of boiler tubes can promptly identify potential defects and enable appropriate remedial measures to prevent further defects. The inspection frequency should be appropriately determined based on the operating conditions and age of the boiler. Generally, a comprehensive inspection should be conducted at least once a year. For boilers operating in harsh environments, the inspection frequency should be shortened.

Boilers are also susceptible to corrosion and other damage during shutdown and standby periods. Therefore, proper management of shutdown and standby conditions is essential. Before shutdown, drain the boiler and dry it. During standby, regularly inspect and maintain the boiler to keep the interior dry and clean to prevent tube corrosion.

During boiler operation, the proper use of compliant chemicals can effectively prevent tube corrosion and scaling. Anticorrosion agents form a protective film on the tube surface, preventing contact between corrosive media and the metal. Descaling agents dissolve scale within the tube, keeping the inner wall clean. However, when using chemicals, strictly follow relevant regulations and instructions to avoid damage to the tubes caused by improper use.

Tube replacement is a cost-effective and core strategy for industrial boiler maintenance. It can effectively resolve tube damage, restore boiler performance, extend its service life, reduce operating costs, and improve safety. Achieving stable, safe, and energy-efficient operation of industrial boilers requires a seamless integration of regular inspections, scientific tube replacement, and water quality management. Regular inspections can identify problems promptly, scientific tube replacements can resolve them, and water quality management can prevent them. Only by properly managing these three aspects can we ensure the long-term effectiveness of industrial boilers and provide reliable power for industrial production.