The papermaking industry is a complex and energy-intensive industry, with significant water and heat consumption associated with its production processes. From raw material processing to pulp production, to paper forming and drying, each step requires significant energy support, with heat being particularly crucial.

So, a question worth pondering is, "Can a paper mill operate without boilers?" The answer is clearly no. Boilers play an indispensable role in many aspects of papermaking.

The key point of this article is that for a paper mill, boilers are more than just a simple heat source; they are the power system for the entire production process, maintaining stable and efficient operation.

Steam boilers play a critical role in the pulping process. High-temperature steam effectively softens wood chips and plant fibers, breaking down the interconnected structures between the fibers, thereby facilitating fiber separation and laying a good foundation for subsequent pulp preparation. By optimizing the steam temperature profile, fiber separation efficiency can be significantly improved, chemical usage can be reduced, and production costs can be lowered. A stable steam supply is crucial for improving pulp quality. If the steam supply is unstable, fluctuating temperatures and pressures will lead to uneven fiber processing, directly impacting paper properties such as strength and density. Furthermore, steam fluctuations can increase equipment wear, shorten the life of cooking equipment, and increase maintenance costs. Furthermore, an unstable steam supply can extend cooking time and reduce production efficiency.

Furthermore, cooking uniformity is closely related to the temperature and pressure control of boiler steam. Precisely controlling steam temperature and pressure ensures uniform heating of raw materials during the cooking process, resulting in more stable and reliable pulp quality. Modern industrial boilers are typically equipped with advanced automatic control systems that monitor and adjust steam parameters in real time. These controls allow for flexible adjustment of steam temperature and pressure based on the requirements of different raw materials and production processes, ensuring an efficient and stable pulping process. Furthermore, recycling steam condensate can further improve energy efficiency, reduce energy costs, and achieve green and sustainable development.

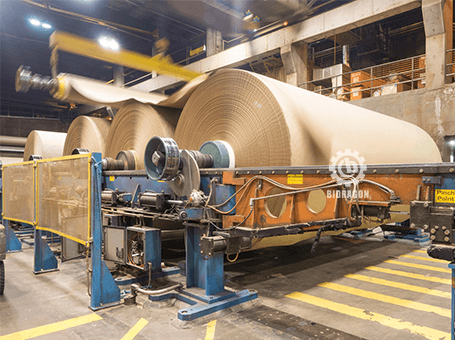

Paper drying is one of the largest energy-consuming steps in the papermaking process, and steam-heated drums are the key to achieving this. This makes the drying process the boiler's primary focus. Steam from the boiler passes through the heating drum, transferring heat to the wet paper web and evaporating moisture. During this process, a stable steam supply ensures uniform drying of the paper web, avoiding areas of excessive dryness or wetness, which directly impacts the paper's strength and appearance. To further improve drying efficiency and paper quality, modern pulp and paper mills often utilize a multi-stage drying process. In the initial stage, high-temperature steam rapidly evaporates a large amount of moisture from the wet paper web's surface; in the subsequent stage, residual heat is used for gentle drying, ensuring that the paper fibers are fully shrunk and set.

In addition, an intelligent control system monitors steam pressure, temperature, and paper moisture content in real time, dynamically adjusting boiler output power. This reduces energy waste while precisely controlling paper weight, flatness, and other parameters, ensuring that the final paper meets the stringent requirements of various applications.

Notably, the use of new insulation materials in steam pipes and heating drums effectively reduces heat loss during transmission, further improving energy efficiency. Some paper mills have also introduced heat pump technology to recycle waste heat generated during the drying process, converting it into low-temperature heat for preheating. To address the unique drying temperature and humidity requirements of different paper grades, the drying system customizes a unique drying curve based on the paper's raw material mix and production process. In the production of some high-end specialty papers, specialized processes such as nitrogen-filled drying are also employed. This creates an oxygen-free environment to prevent oxidation and discoloration during the drying process, ensuring the highest quality standards.

In addition to providing heat, the steam generated by boilers serves as a power source for various production equipment within the paper mill, such as turbines, pumps, and agitators. These devices play a vital role in raw material transportation, pulp mixing, and wastewater treatment, and a stable steam supply ensures their normal operation. The reeling and calendering processes of the paper machine require extremely stable power. The high-pressure steam output of the boiler can precisely match these operational requirements, ensuring the smoothness and finish of the paper.

In some locations where there is no external power grid or the external power supply is unstable, the boiler can also support waste heat power generation within the mill. Through related equipment, steam heat is converted into electricity, meeting part of the factory's electricity needs and improving energy self-sufficiency. Especially during peak electricity demand periods, when the external power grid is unable to meet the simultaneous operation of high-power equipment, the boiler-driven power generation system can quickly intervene to ensure the continuous operation of key equipment such as paper machines and pulpers.

Furthermore, the cogeneration model implemented by the boiler allows waste heat generated during power generation to be reused for heating and other processes within production, significantly improving energy utilization and reducing energy costs. For example, the low-pressure steam generated after power generation can be directly used in the washing process after pulp cooking or provide a gentle heat source for the drying cylinders in the paper drying section. This cascaded energy utilization approach makes the boiler the power center of the entire papermaking process.

The performance of boilers in paper mills is directly related to production efficiency, cost, environmental protection, and stability, and therefore has many key performance requirements, which form the core of this article.

Fuel costs account for a significant proportion of a paper mill's total operating costs, and boiler efficiency directly impacts fuel consumption, which in turn significantly impacts profit margins. High-efficiency boilers can produce sufficient steam while consuming less fuel, thereby reducing energy consumption and effectively controlling costs.

Modern industrial boilers utilize a variety of advanced technologies to improve efficiency. For example, condensing boilers recover latent heat from flue gases, improving energy efficiency; and waste heat recovery technologies recycle heat from high-temperature flue gases and wastewater, further improving overall boiler efficiency.

Papermaking is a continuous process with closely interconnected links. Even minor fluctuations in steam supply can lead to substandard product quality and, in severe cases, even production halts, resulting in significant economic losses.

Thus, boilers must possess stable output, placing extremely high demands on their control systems. Precision control systems monitor steam parameters such as temperature and pressure in real time and rapidly adjust them based on production needs, ensuring stable and accurate steam output and smooth, continuous production.

With growing environmental awareness and increasingly stringent environmental regulations, paper mill boiler emissions must meet local standards for pollutants such as NOx, SOx, and particulate matter.

To meet these requirements, industrial boilers employ a variety of advanced environmental technologies. Low-NOx combustion technology optimizes the combustion process to reduce nitrogen oxides; selective catalytic reduction (SCR) effectively treats generated nitrogen oxides; and desulfurization technology reduces sulfur dioxide content in flue gas, thereby improving boiler environmental compliance.

At the same time, corporate ESG (Environmental, Social, and Corporate Governance) responsibilities are driving the adoption of clean boiler technologies, prompting paper mills to prioritize environmental protection while pursuing economic benefits.

In the papermaking industry, alkali recovery boilers play a unique and important role. It excels in recovering chemicals such as NaOH and sulfide. By burning black liquor generated during the pulping process, it not only recovers heat energy for steam generation, but also recovers chemicals for reuse in the pulping process. Specifically, the black liquor is incinerated at high temperatures within the boiler, converting organic matter into heat to drive the steam system while inorganic matter is concentrated in a molten state. Subsequent processes such as dissolution and filtration allow key chemicals such as sodium hydroxide and sodium sulfide to be precisely separated from the combustion products.

This synergistic effect achieves a closed-loop chemical utilization cycle, significantly reducing chemical consumption and lowering production costs. It also reduces environmental pollution caused by chemical emissions, achieving dual benefits for both environmental protection and cost control. Furthermore, the efficient operation of the alkali recovery boiler significantly improves resource utilization for papermaking enterprises. The steam generated not only meets the power needs within the plant, but any excess can even be supplied externally, further enhancing the company's economic benefits and truly establishing a green, circular production model.

In addition to their primary role in production, industrial boilers also perform a variety of auxiliary functions. High-temperature steam can effectively clean and sterilize production equipment, removing dirt and microorganisms from its surfaces.

Maintaining equipment sterile and free of scale reduces equipment failures, improves production efficiency, and prevents microorganisms and dirt from negatively impacting paper quality.

In addition, steam can control humidity and temperature within the plant, providing a stable environment for paper production and further enhancing product stability.

In summary, industrial boilers play a comprehensive and critical role in paper mills. They not only provide essential heat for pulping and drying processes, but also serve as the power source for various production equipment. They also play an important role in process control, chemical recovery, and assisting in cleaning and disinfection.

Therefore, boiler selection, routine maintenance, and technical upgrades are crucial for paper mills. Selecting an efficient, stable, and environmentally friendly boiler can help paper mills achieve high-quality production, reduce energy consumption, and minimize environmental pollution, making it a key step towards sustainable development. Boilers are the irreplaceable "heart" of a paper mill, maintaining the smooth operation and development of the entire production system.