An industrial steam boiler is a device that converts energy in the form of fuel or electricity into heat energy for heating water to produce steam. It transmits and converts heat through a complex system to provide a continuous and stable heat source for industrial production. As a pressure vessel, industrial steam boilers must strictly follow a series of safety standards and specifications during the design, manufacture and operation process to ensure its safe and stable operation.

An industrial steam boiler is a pressure vessel that produces steam by heating water to boiling by burning fuel (such as natural gas, fuel oil, coal, etc.) or using electricity. The basic principle is to use the heat energy or electricity generated by fuel combustion to transfer heat to water through a heat exchanger, so that the temperature of the water rises and is eventually converted into steam.

In a steam boiler, the process of heat transfer from a heat source to water involves a complex heat exchange mechanism. Taking a fuel-burning boiler as an example, the fuel burns in the combustion chamber and releases a large amount of heat energy, which is transferred to the boiler water through the heating surface of the boiler (such as furnace tubes, water-cooled walls, etc.). The design and material selection of the heating surface directly affect the heat transfer efficiency. Efficient heat exchange can maximize the use of the heat generated by the fuel and increase steam production.

In the manufacturing industry, steam boilers are widely used in food processing, pharmaceutical, textile and other industries for cooking, drying, sterilization and other processes of materials; in the chemical industry, steam provides the necessary heat and pressure conditions for chemical reactions; in the power industry, steam drives the turbine to rotate and generate electricity. Different industries have different requirements for steam pressure, temperature and quality, which also determines that the selection and design of boilers need to be customized according to specific application scenarios.

Due to the high temperature and high pressure steam inside the boiler, once an accident occurs, the consequences are disastrous. Therefore, all countries have formulated strict regulations and standards to regulate the design, manufacture, installation, inspection and operation of boilers. These regulations cover many aspects such as material selection, strength calculation, safety accessories configuration, regular inspection, etc. of the boiler to ensure the safe operation of the boiler throughout its life cycle.

Heat source (fuel/electricity)

Depending on the type, the heat source of industrial steam boilers can be divided into fuel combustion and electricity. Boilers that use fuel as a heat source, common fuels include natural gas, fuel oil, coal and biomass. Under the action of the burner, the fuel is fully mixed with the air and then burned to release heat energy; while electric boilers convert electrical energy into heat energy through resistance wire or electromagnetic induction.

Water heating

The water in the boiler enters the boiler body through the water feed pump, absorbs heat under the action of the heating surface, and the temperature gradually rises. In order to ensure uniform heating of the water and good heat exchange effect, a reasonable water circulation system is usually set inside the boiler to keep the water flowing in the boiler to avoid local overheating.

Steam generation

When the water is heated to the boiling point, it will continue to absorb heat and be converted into steam. In this process, the state of the water changes, the volume expands rapidly, and steam with a certain pressure and temperature is formed. The quality of steam (such as dryness, pressure, temperature, etc.) directly affects its application effect in industrial production.

Steam distribution

The generated steam is transported to various steam-using equipment through steam pipes. During the transportation process, the steam needs to be properly reduced, regulated and metered to meet the requirements of different equipment for steam parameters. At the same time, in order to reduce the heat loss of steam during transportation, the steam pipe is usually insulated.

The burner is a key device for fuel combustion. It is responsible for fuel transportation, air ratio and ignition control, which directly affects combustion efficiency and pollutant emissions; the control system monitors the operating parameters of the boiler in real time (such as pressure, temperature, water level, etc.), and automatically adjusts the operating status of equipment such as burners and feed water pumps according to the set values to ensure safe and stable operation of the boiler; the condensate recovery system collects the condensate discharged from the steam-using equipment, and returns it to the boiler as feed water after treatment, thereby improving the utilization rate of water resources and energy efficiency.

Calcium and magnesium ions in water are prone to scale formation under high temperature and high pressure, which adheres to the heating surface of the boiler, reduces the heat transfer efficiency, and even causes overheating and damage to the heating surface. Therefore, industrial steam boilers usually need to use softened water or reverse osmosis water as feed water. Softened water removes calcium and magnesium ions from the water through ion exchange resin, while reverse osmosis water filters out most of the impurities and ions in the water through a semipermeable membrane, ensuring that the water quality entering the boiler meets the requirements and extending the service life of the boiler.

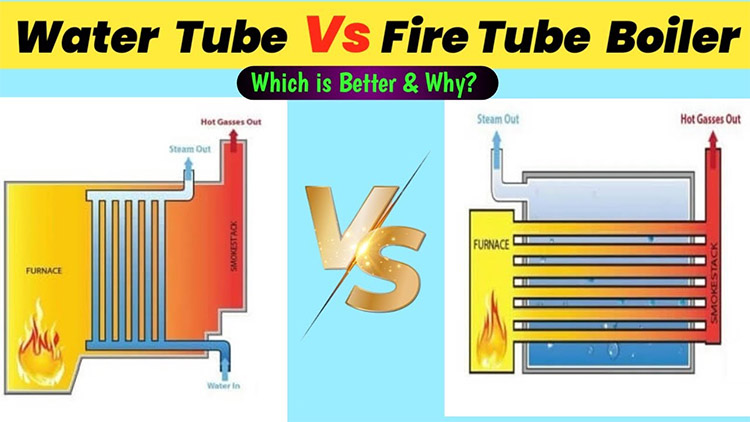

Fire tube boilers have the characteristics of low maintenance cost, wide application, and high efficiency. In this boiler, high-temperature flue gas flows in the tube and water absorbs heat outside the tube. It has a simple structure and is easy to operate. It is suitable for industries with relatively low requirements for steam pressure and output, such as food processing, pharmaceuticals, and heating.

Water tube boilers can withstand high pressures and have high thermal efficiency, making them suitable for large factories. In water tube boilers, water flows in the tube and high-temperature flue gas flushes outside the tube. This structure is conducive to improving heat exchange efficiency and steam output. It is commonly used in industries such as electricity, chemical industry, and papermaking that require a large amount of high-temperature and high-pressure steam.

Electric boilers have the advantages of being clean, compact, and zero-emission. It does not require the burning of fuel and does not have the problem of exhaust gas emissions. It is very suitable for installation in cities, indoors, and areas with high environmental requirements. In addition, electric boilers start quickly and are flexible to adjust, which can meet some production needs that require a high response speed for steam supply.

Biomass boilers use renewable biomass fuels (such as wood waste, crop straw, etc.) as energy, and are environmentally friendly and energy-saving. It is widely used in agriculture, rural industries, and enterprises that focus on sustainable development. It can not only reduce the energy costs of enterprises, but also reduce dependence on fossil energy and realize the resource utilization of waste.

There are obvious differences in design, material selection and application scenarios between high-pressure boilers and low-pressure boilers. High-pressure boilers require high-strength materials and complex structural designs to withstand higher pressures. They are usually used in fields such as power generation and large-scale chemical industry that require high steam parameters; while low-pressure boilers have relatively simple structures and low costs, and are suitable for heating, small-scale processing, and other occasions where steam pressure is not required. When choosing, enterprises need to comprehensively consider factors such as steam pressure, temperature, and output according to their own production needs.

Modular and combined boilers are flexible, scalable, and easy to maintain. They can adjust the capacity of the boiler by increasing or decreasing the number of modules according to the production scale and steam demand of the enterprise. This design concept adapts to the ever-changing production needs of modern manufacturing and provides enterprises with smarter and more efficient steam solutions.

Fuel types used

Common fuels for industrial steam boilers include natural gas, oil, coal and biomass. Natural gas has the advantages of cleanliness, high combustion efficiency and convenient operation, and is one of the most widely used fuels at present; petroleum fuels (such as diesel and heavy oil) have high calorific value, but the price is relatively high, and certain pollutants will be produced after combustion; coal is a traditional fuel with low price, but a large amount of dust, sulfur dioxide and nitrogen oxides will be produced during combustion, which will put great pressure on the environment; biomass fuels are widely available and renewable, and the pollutants emitted by combustion are relatively few, which meets environmental protection requirements.

Environmental and economic considerations for each fuel

Different fuels have significant differences in environmental impact and economic cost. From an environmental perspective, natural gas combustion produces the least pollutants, followed by biomass fuels, and coal has the most serious pollutant emissions; from an economic cost perspective, coal prices are relatively low, but with the increase in environmental protection requirements, its environmental protection management costs continue to increase; natural gas and petroleum fuels are relatively expensive, but considering their combustion efficiency and environmental advantages, their comprehensive costs are also competitive in some areas with strict environmental requirements. When choosing fuel, companies need to consider local fuel supply, environmental protection policies, and economic costs.

The role of combustion

Combustion is the key process of converting fuel chemical energy into thermal energy. In order to achieve efficient combustion, it is necessary to ensure that the fuel and air are fully mixed and provide appropriate combustion temperature and time. Reasonable combustion organization can make the fuel burn completely, maximize the release of heat, improve the thermal efficiency of the boiler, and reduce pollutant emissions.

The importance of fuel-to-air ratio

The ratio of fuel to air (i.e., air-fuel ratio) directly affects combustion efficiency and pollutant emissions. When the air-fuel ratio is too low, the fuel cannot be fully burned, which will lead to the production of incomplete combustion products (such as carbon monoxide, hydrocarbons, etc.), reduce thermal efficiency and increase fuel consumption; when the air-fuel ratio is too high, too much air will take away a lot of heat, which will also reduce thermal efficiency and increase the generation of nitrogen oxides. Therefore, accurate control of the air-fuel ratio is the key to improving combustion efficiency and reducing emissions.

Complete combustion and incomplete combustion

Complete combustion can convert all chemical energy in the fuel into thermal energy, reduce pollutant emissions and reduce fuel costs; while incomplete combustion will not only cause fuel waste, but also produce a large amount of harmful gases and particulate matter, increasing the environmental protection cost of enterprises. It is an important way to improve boiler performance to achieve complete combustion of fuel by optimizing combustion equipment and control technology.

Real-time control technology in modern boiler systems

Modern industrial steam boilers widely use advanced real-time control technologies, such as combustion optimization technology based on sensors and automatic control systems. These systems monitor the operating parameters of the boiler in real time (such as temperature, pressure, oxygen content, etc.), automatically adjust the fuel supply and air flow, realize dynamic optimization of the combustion process, and ensure that the boiler operates in an efficient, stable and environmentally friendly state.

How burners manage fuel delivery, airflow and ignition

Industrial burners are the core components of boilers to achieve efficient combustion. Through precise design and control, it achieves accurate fuel metering and delivery, reasonably adjusts air flow, ensures uniform mixing of fuel and air, and achieves stable ignition through reliable ignition devices. Different types of burners are suitable for different fuels and boiler conditions, and enterprises need to choose the right burner according to actual needs.

Adaptation of burners to fuel types and pressure requirements

In order to adapt to different fuel types and pressure requirements, the structure and performance of the burner need to be adjusted accordingly. For example, for natural gas burners, it is necessary to design suitable gas nozzles and air conditioning devices according to the pressure and composition of natural gas; for oil burners, it is necessary to consider factors such as the viscosity and atomization effect of the fuel. Through the optimization design and adjustment of the burner, the adaptability of the burner to different fuels and working conditions can be improved to ensure the stability and efficiency of combustion.

Economizer

Economizer is a heat exchange device installed in the flue at the tail end of the boiler. It uses the high-temperature flue gas discharged from the boiler to heat the boiler feed water, recover part of the heat in the flue gas, and improve the thermal efficiency of the boiler. By using an economizer, not only can fuel consumption be reduced, but also the flue gas emission temperature can be reduced, and thermal pollution to the environment can be reduced.

Deaerator

Dissolved oxygen in water can cause serious corrosion to the metal parts of the boiler and shorten the service life of the boiler. The deaerator removes dissolved oxygen in the feed water by heating or chemical methods to protect the heating surface and pipelines of the boiler from corrosion. Common deoxygenation methods include thermal deoxygenation and chemical deoxygenation. Enterprises can choose the appropriate deoxygenation method according to actual conditions.

Drainage system

During the operation of the boiler, impurities and salts in the water are continuously concentrated, and regular drainage is required to maintain stable water quality and pressure. The drainage system discharges high-concentration impurities and salts in the boiler water by controlling the drainage volume and drainage time, preventing scaling and corrosion, and ensuring the safe and stable operation of the boiler. At the same time, reasonable sewage discharge operation can also improve steam quality and reduce the impact on steam-using equipment.

Preventing scaling and corrosion

Scaling and corrosion are the main factors affecting the heat transfer efficiency and service life of boilers. By strictly treating the boiler feed water and removing harmful substances such as calcium, magnesium ions, and dissolved oxygen in the water, scaling and corrosion can be effectively prevented. In addition, suitable water treatment agents can be added to the boiler water to further inhibit the development of scaling and corrosion.

Impact on energy efficiency and boiler life

Good water treatment and heat transfer optimization measures can significantly improve the energy efficiency of the boiler and reduce operating costs. Reducing scaling can improve heat transfer efficiency and reduce fuel consumption; preventing corrosion can extend the service life of the boiler and reduce equipment maintenance and replacement costs. Therefore, paying attention to water treatment and heat transfer optimization is the key to ensuring the long-term and efficient operation of the boiler.

Chemical dosing and filtration solutions

Chemical dosing is a common method of preventing scaling and corrosion by adding chemical agents such as scale inhibitors and corrosion inhibitors to boiler water. At the same time, using appropriate filtering equipment (such as mechanical filters, activated carbon filters, etc.) to pre-treat boiler feed water can further remove impurities such as suspended matter and colloids in the water and improve water quality. Enterprises need to reasonably select chemical dosing and filtration solutions based on the actual operation of the boiler to ensure the water treatment effect.

When selecting an industrial boiler, the first thing to do is to accurately calculate the required amount of steam based on the company's production process requirements. If the boiler capacity is too large, it will cause idle equipment and energy waste; if the capacity is too small, it will not be able to meet production needs and affect production efficiency. Therefore, it is necessary to comprehensively consider factors such as steam consumption, steam consumption time and steam parameters in each link of the production process to select a boiler with appropriate capacity.

Different production processes have different requirements for steam pressure. When selecting a boiler, it is necessary to clarify the steam pressure range required in the production process to ensure that the boiler can provide steam pressure that meets the process requirements. At the same time, it is also necessary to consider the pressure loss of steam during transportation and reasonably select the rated pressure of the boiler.

The availability and cost of fuel are important factors affecting the economic efficiency of boiler operation. Enterprises should give priority to fuels with abundant local resources and reasonable prices. At the same time, it is also necessary to consider the stability of fuel supply and transportation costs to ensure that the boiler can operate continuously and stably.

Energy efficiency is an important indicator for measuring boiler performance. When selecting a boiler, you should pay attention to its thermal efficiency and fuel-to-steam ratio. Choosing a boiler with high energy efficiency can reduce operating costs and energy consumption. In addition, the energy efficiency of boilers can be further improved by adopting advanced combustion technology, waste heat recovery devices and other measures.

With increasingly stringent environmental protection requirements, enterprises must ensure that the equipment meets local emission standards and environmental regulations when selecting boilers. Different regions have different requirements for boiler pollutant emission limits (such as sulfur dioxide, nitrogen oxides, particulate matter, etc.). Enterprises need to choose boilers that can meet these requirements and equip them with corresponding environmental protection equipment (such as desulfurization, denitrification, dust removal devices, etc.).

Considering the future development of the enterprise and changes in production processes, choosing boilers with modularity and scalability can provide enterprises with greater flexibility. Modular boilers can increase or decrease the number of modules at any time according to the needs of the enterprise and adjust the capacity of the boiler; the scalable boiler design also facilitates enterprises to upgrade and transform equipment in the future to meet changing production needs.

The pressure vessel is the core component of the steam boiler, which bears high-temperature and high-pressure steam. The design and manufacture of pressure vessels must strictly follow relevant standards and specifications to ensure their strength, sealing and safety. When choosing a boiler, you need to pay attention to the material quality, manufacturing process and inspection certificate of the pressure vessel to ensure that it meets the requirements of use.

The burner system is responsible for the combustion process of the fuel, and its performance directly affects the combustion efficiency and pollutant emissions of the boiler. An efficient burner system should have accurate fuel metering, reasonable air ratio and stable ignition function, and be able to adapt to different types of fuels and boiler conditions.

The control system is the guarantee for the safe and stable operation of the boiler. It monitors the operating parameters of the boiler (such as pressure, temperature, water level, flue gas composition, etc.) in real time through sensors, and automatically adjusts the operating status of equipment such as burners, feed water pumps, and drain valves according to the set values to achieve automatic control of the boiler. Modern boiler control systems also have functions such as fault diagnosis, alarm and remote monitoring, which improves the operating safety and management efficiency of the boiler.

The heating surface is a key component for the boiler to achieve heat exchange. It transfers the heat from the heat source to water to convert it into steam. The design and material selection of the heating surface have an important impact on the heat transfer efficiency and boiler performance. Common forms of heating surfaces include furnace tubes, water-cooled walls, superheaters, etc. Their structures and layouts need to be optimized according to the type and operating requirements of the boiler.

The water treatment and water supply system provides the boiler with water supply that meets the water quality requirements to ensure the safe and stable operation of the boiler. The water treatment system removes impurities and harmful substances in the water through softening, filtration, deoxygenation and other processes; the water supply system transports the treated water to the boiler and automatically adjusts the water supply according to the water level changes of the boiler.

The exhaust system discharges the flue gas generated by boiler combustion, while controlling the exhaust gas temperature and emission concentration; the sewage system regularly discharges high-concentration impurities and salts in the boiler water to maintain stable water quality and pressure. Reasonable design and operation of the exhaust and sewage system is crucial to ensure the thermal efficiency, safety and environmental protection performance of the boiler.

Additional equipment to improve safety and efficiency

Economizer, deaerator, feed water tank: recover waste heat, remove dissolved oxygen, store feed water, and improve boiler efficiency and safety.

Heat recovery system: further recover waste heat in the steam system for preheating air or heating other media to improve energy utilization.

Monitoring sensors and intelligent automation control: real-time monitoring of boiler operating parameters, automatic control and fault warning, ensuring safe operation of the boiler and improving management efficiency.

Industrial steam boilers are not only simple heating equipment, but also a key system to promote industrial production efficiency and productivity. Choosing a suitable boiler requires comprehensive consideration of technical requirements, energy goals and operational safety. Through reasonable selection and scientific maintenance, steam boilers can effectively reduce enterprise operating costs, reduce pollutant emissions, and provide strong support for the long-term sustainable development of industrial enterprises.