In modern manufacturing, energy efficiency has become a core issue for corporate sustainable development. With the continued growth of global energy demand and rising fuel prices, the manufacturing industry faces increasingly severe cost pressures. At the same time, the sustainable development challenges posed by climate change are prompting countries and industries to impose stricter requirements on carbon emissions and energy waste. Against this backdrop, reducing energy consumption, lowering operating costs, and achieving environmental compliance have become critical issues facing the manufacturing industry. Waste heat boilers, as a device that efficiently recovers waste heat from industrial production processes, are becoming a key solution to these challenges, bridging the gap between energy utilization and sustainable development in the manufacturing industry.

A waste heat boiler is essentially a heat recovery device that utilizes waste heat generated during industrial production, such as high-temperature flue gases and waste heat fluids, to generate steam or hot water. Its core concept is "recycling," converting waste heat that would otherwise be directly discharged into the environment, causing energy waste and heat pollution, into a reusable energy form. Compared to traditional boilers, the core difference lies in how they obtain their heat source: traditional boilers require specialized fuels to generate heat, which in turn generates steam or hot water. Waste heat boilers, on the other hand, do not consume significant amounts of additional fuel and rely primarily on naturally occurring waste heat from industrial processes. They may only require a small amount of supplemental fuel when waste heat is insufficient.

In industrial applications, waste heat boilers have a wide range of applications, covering multiple key manufacturing sectors. In the steel industry, they can recover heat from high-temperature flue gases emitted by equipment such as blast furnaces and converters; in the cement industry, they can recover waste heat from cement kiln calcination; and in the chemical industry, they can recover waste heat from equipment such as reactors and cracking furnaces. Furthermore, waste heat boilers play a vital role in energy recovery in industries such as glass manufacturing, non-ferrous metal smelting, and power generation, making them a crucial piece of equipment for improving energy efficiency across various sectors.

Manufacturing is a major energy consumer. Certain energy-intensive industries, such as steel, cement, and chemicals, have extremely high energy intensities. Their production processes require significant amounts of energy to maintain high temperatures and high pressures, and energy costs contribute significantly to a company's total operating costs. However, these industries are plagued by serious energy waste: large amounts of high-temperature waste heat, such as heat carried by flue gases and wastewater, are discharged without being recovered. This not only significantly wastes energy resources but also further increases operating costs. For example, in the steel industry, high-temperature flue gases generated during blast furnace smelting can reach temperatures exceeding 1000°C. Without recovery, this heat is completely lost, increasing the environmental heat dissipation burden.

In addition to energy waste and cost pressures, the manufacturing industry also faces increasingly stringent environmental regulations and compliance pressures. To combat climate change, countries around the world have introduced stricter carbon emission limits and environmental standards, requiring companies to reduce pollutant and greenhouse gas emissions. For high-energy-consuming manufacturing companies, failure to meet these regulatory requirements could lead to risks such as fines, production suspensions, and even impacts on market access and brand image. This makes energy management and environmental compliance essential for survival and development.

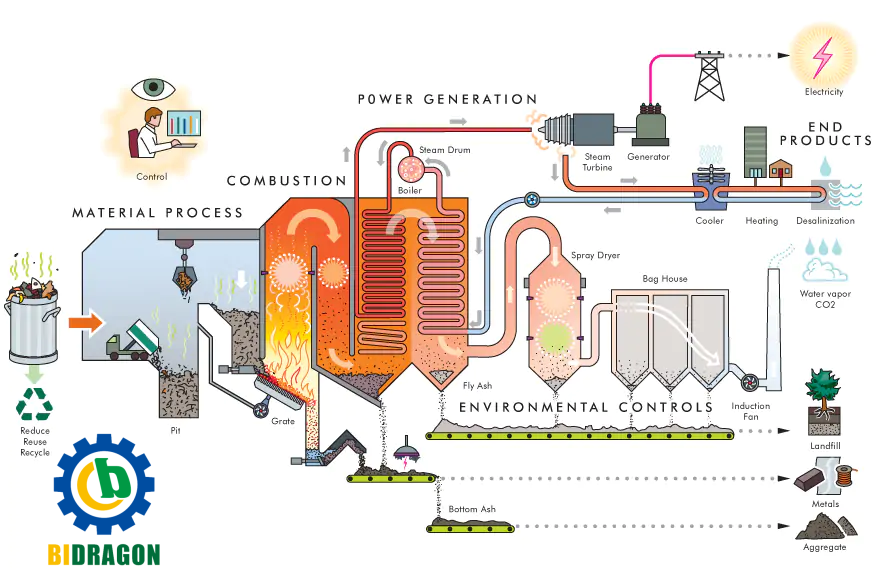

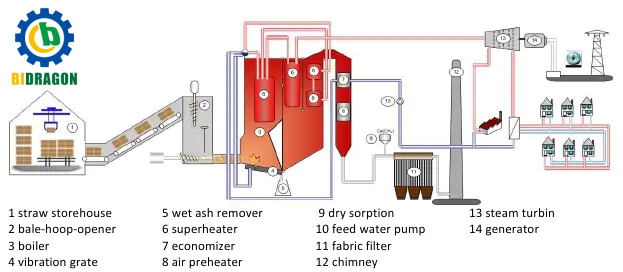

The operating principle of a waste heat boiler revolves around the core principle of "waste heat recovery - energy conversion - efficiency improvement." Through a series of sophisticated technical processes, it achieves efficient utilization of industrial waste heat. The specific process can be divided into the following key links:

The first step in the operation of a waste heat boiler is to efficiently capture the high-temperature waste gases generated during industrial production. When production equipment in industries such as steel, cement, and chemicals operates, it continuously emits flue gases containing large amounts of waste heat. These flue gases typically have temperatures between 300°C and 1200°C, making them a significant source of waste heat. A waste heat boiler uses a specially designed flue gas collection system to direct this high-temperature flue gas into the heat exchange channels within the boiler. During this process, to ensure efficient waste heat capture, the system monitors and controls the flue gas flow and temperature in real time. It also optimizes flue gas design to minimize heat loss during flue gas transmission, ensuring that as much high-temperature flue gas as possible enters the heat exchange process.

When the high-temperature flue gas enters the waste heat boiler (HRSG), the core energy conversion process begins. The HRSG houses numerous heat exchange tube bundles, each containing water or other heat transfer media. As the high-temperature flue gas flows through the tube bundles, it transfers heat to the media within the bundles through heat conduction and convection. With the continuous input of heat, the water within the bundles gradually heats to its boiling point, converting it into saturated steam. If higher steam parameters are required, the system can further heat the saturated steam to superheated steam. This generated steam can be used directly in industrial processes, such as driving production equipment and providing process heating, or it can be fed to a steam turbine, which then drives a generator, ultimately converting the waste heat into directly usable electricity, achieving cascaded energy utilization.

Through the aforementioned waste heat recovery and energy conversion process, waste heat boilers can significantly reduce an enterprise's reliance on external fuels, thereby reducing fuel consumption. In manufacturing enterprises without waste heat boilers, production steam and electricity are entirely dependent on traditional boilers or purchased electricity, consuming significant amounts of fuels such as coal and natural gas. However, with waste heat boilers, enterprises can utilize recovered waste heat to independently generate some or all of their steam and electricity needs, requiring traditional boilers to supplement the supply only when waste heat is insufficient. This "waste heat-primary, fuel-supplemented" energy supply model can significantly reduce external fuel consumption. Industry data shows that enterprises that effectively utilize waste heat boilers can reduce fuel consumption by 15% to 30%, directly reducing their energy costs.

In the energy optimization system for manufacturing processes, waste heat boilers are deeply integrated into the production chain, forming a complete energy optimization solution from heat recovery circuit construction, supply and demand balancing, process integration, to continuous efficiency improvement. Waste heat boilers (WHRGs) create a precise heat recovery loop, breaking the traditional "one-way energy consumption and loss" model and establishing a closed-loop energy system. High-temperature waste heat from production equipment is captured by flue gas collection devices and transferred to the boiler's internal heat exchanger in the core heat exchange area, converting waste heat into usable thermal energy. After cooling, the waste heat is pre-treated and used in auxiliary production processes or to preheat fuel and air, completing a closed-loop cycle of "waste heat capture - heat conversion - secondary utilization."

WHRGs utilize intelligent control systems that integrate with production processes to dynamically adjust energy output, precisely matching recovered heat to process requirements. For example, in chemical production, heat exchange efficiency is adjusted based on the temperature requirements of the reactor at different stages. Thermal storage devices achieve "peak-to-valley" balance, avoiding energy waste caused by supply-demand mismatches.

Integrating steam or hot water generated by WHRGs with auxiliary production equipment such as pumps and fans reduces reliance on external energy sources. For example, the food processing industry uses waste heat steam to drive steam turbines, powering pumps and fans. The papermaking industry uses waste heat hot water for pulp preheating and drying, reducing external energy purchases and transmission losses.

Waste heat boilers, serving as the "energy hub," optimize energy allocation in production processes. Companies can use their operational data to identify opportunities for improvement, such as adjusting core equipment parameters and retrofitting auxiliary equipment. These opportunities can be leveraged through intelligent energy management systems to monitor energy consumption in real time. Through a cycle of "application - data feedback - optimization - reapplication," they can drive a continuous reduction in the energy intensity of production lines.

Waste heat boilers offer multifaceted advantages to manufacturing companies. The first is reduced economic costs. By recycling waste heat to generate steam or electricity, companies can significantly reduce their reliance on external fuel and electricity, directly lowering energy costs. Furthermore, because waste heat boilers primarily rely on waste heat, their fuel consumption in daily operations is significantly lower than that of traditional boilers, further reducing operating costs and providing strong support for increasing profit margins.

Secondly, waste heat boilers can significantly improve a company's overall energy efficiency. Traditional manufacturing often suffers from low primary energy efficiency and significant waste heat. However, waste heat boilers, by recovering and utilizing waste heat for secondary use, create an energy cycle encompassing "production energy - waste heat recovery - secondary energy use." This extends the company's energy utilization chain, converting previously wasted waste heat into effective energy, thereby improving overall energy efficiency and reducing idle and wasted energy resources.

Environmentally, the use of waste heat boilers can effectively reduce pollutant and greenhouse gas emissions. Reduced fuel consumption reduces emissions of pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, as well as greenhouse gas emissions such as carbon dioxide. This helps companies mitigate their environmental impact and better address the challenges of global climate change.

In addition, the use of waste heat boilers can enhance a company's market competitiveness and regulatory compliance. In a market environment characterized by rising energy costs and increasingly stringent environmental regulations, companies equipped with waste heat boilers can gain an advantage in market competition with lower operating costs and better environmental performance. At the same time, their achievements in energy conservation and emission reduction can also help companies easily meet the requirements of various environmental regulations, avoid compliance risks, and even enhance their social image, thus helping them expand their market and attract cooperation.

Integrating waste heat boilers into manufacturing systems requires different strategies depending on whether the company is building a new plant or renovating an existing one, carefully considering key factors such as design, compatibility, and installation.

For existing plant renovations, the core focus is on refurbishing the waste heat boiler. Before renovation, companies should conduct a comprehensive investigation and assessment of the waste heat characteristics of existing production equipment, including temperature, flow rate, composition, energy requirements, steam pressure, temperature, power requirements, and plant layout, to identify the potential and limitations of waste heat recovery. Based on this, a targeted renovation plan should be designed. For example, if the existing flue cannot meet the flue gas transportation needs of the waste heat boiler, the flue should be extended or modified. If the existing energy pipeline network cannot accommodate the steam generated by the waste heat boiler, the steam pipeline network design should be optimized. During the renovation process, the continuity of existing production should be fully considered, and key construction should be carried out during the off-season or equipment maintenance period to minimize the impact on normal production.

In terms of design and engineering, it is important to focus on the synergy between the waste heat boiler and the existing production system. The design must ensure that waste heat capture by the HRSG does not disrupt the normal operation of existing production equipment. Furthermore, the steam or electricity generated by the HRSG can be precisely matched to the needs of the production system, avoiding energy waste or insufficient supply. Furthermore, the safety and stability of the equipment must be considered. For example, a comprehensive flue gas purification system should be designed to reduce dust wear on the HRSG, and pressure and temperature control systems should be designed to prevent overpressure and overtemperature operation, ensuring the long-term stable operation of the integrated system.

Compatibility is another key consideration during the integration process. The HRSG must be compatible with existing production equipment, energy management systems, and control systems. At the equipment level, the HRSG's interfaces must be compatible with those of existing equipment to avoid connection failures. At the control system level, the HRSG's operating data must be connected to the factory's central control system to achieve coordinated control of the HRSG and production equipment. For example, if changes in production equipment load cause fluctuations in waste heat parameters, the control system can automatically adjust the HRSG's operating status to ensure a stable energy supply.

To minimize production downtime during installation, companies must develop a detailed installation plan and contingency plan. Before installation, the necessary equipment, components, and tools were prepared in advance, and the timelines and responsibilities for each construction phase were clearly defined. During installation, a modular construction approach was adopted, with some equipment prefabricated in the factory and then assembled on-site, shortening on-site construction time. Furthermore, close collaboration with the production department was carried out to rationally schedule construction times, prioritizing off-peak production periods or periods of equipment downtime. If production interruptions were necessary, a temporary energy supply plan was developed in advance to ensure that critical production processes were not affected, minimizing the impact of the installation process on business operations.

Waste heat boilers offer significant advantages in helping manufacturing companies meet environmental regulations and achieve sustainable development, manifesting themselves in multiple ways. First, they can help companies meet increasingly stringent emission standards. With the continuous evolution of global environmental regulations, countries are imposing lower limits on pollutant emissions from industrial enterprises. By reducing fuel consumption, waste heat boilers directly reduce the amount of pollutants generated during fuel combustion, enabling companies to easily meet or even fall below regulatory requirements, avoiding the risk of fines or production suspensions due to excessive emissions.

Waste heat boilers also make significant contributions to greenhouse gas emissions reduction. Fuel combustion is a major source of carbon dioxide emissions in industrial enterprises. Waste heat boilers (HRSGs) can significantly reduce CO2 emissions by recovering waste heat and replacing some of the fuel consumed. For example, if a chemical company consuming 100,000 tons of natural gas annually can reduce its natural gas consumption by 20% after installing HRSGs, it can reduce CO2 emissions by approximately 44,000 tons annually (calculated based on the CO2 emission coefficient for natural gas combustion). This emission reduction not only helps companies fulfill their social responsibility to address global climate change but also creates potential revenue in the carbon trading market, creating additional economic value for the company.

HRSGs also play a key role in corporate sustainability strategies, particularly in their corporate social responsibility (CSR) and environmental, social, and governance (ESG) practices. Investors, customers, and the public are increasingly concerned about a company's environmental performance, and a company's ESG rating has become a significant factor influencing its market image and investment appeal. The use of HRSGs can enhance a company's ESG performance in areas such as energy efficiency and emissions reduction, helping it establish a "green manufacturing" brand image and strengthen investor and customer trust. It can also meet employees' demands for a sustainable work environment, fostering a sense of belonging and enhancing corporate cohesion. Furthermore, many countries and regions have introduced a series of incentive policies to encourage businesses to adopt energy-saving and emission-reduction technologies. The use of waste heat boilers provides businesses with opportunities to capitalize on these policies. For example, some countries offer tax exemptions, financial subsidies, or priority support in energy supply and project approvals to businesses that employ waste heat recovery technology. In some regions, businesses can also receive additional financial rewards through participation in renewable energy certificate trading and energy-saving benefit sharing mechanisms. These incentives not only reduce the initial costs and operational burdens of implementing waste heat boilers, but also further enhance the economic feasibility of waste heat boiler applications, encouraging greater adoption of this technology.

In summary, waste heat boilers, as highly efficient energy recovery equipment, play an irreplaceable role in addressing energy efficiency challenges in modern manufacturing. From a core value perspective, by capturing waste heat from industrial processes and converting it into usable steam or electricity, they not only significantly reduce fuel consumption and operating costs, but also improve overall energy efficiency while reducing pollutant and greenhouse gas emissions, helping businesses achieve a win-win situation both economically and environmentally.