In power plants and various industrial production scenarios, boilers, as core thermal power equipment, perform the critical function of converting the chemical energy of fuel into heat, generating steam to drive the operation of the units. Their stable and safe operation is directly related to the efficiency and safety of the entire production system and is a crucial cornerstone for ensuring production continuity and personnel safety.

Boiler hydrostatic testing, as a core safety verification step before boiler commissioning and after regular maintenance, plays an irreplaceable role. By injecting water under a certain pressure into the boiler's pressure-bearing components, it verifies their structural strength and tightness. It is a key method for identifying potential equipment hazards and ensuring safe boiler operation.

This article comprehensively focuses on boiler hydrostatic testing, systematically explaining its importance, specific requirements, test scope, preliminary preparation, detailed operating procedures, acceptance criteria, and safety precautions, providing professional and comprehensive operational and theoretical reference for relevant engineers and technicians.

Boiler hydraulic pressure testing is the first line of defense for ensuring safe and stable boiler operation. Its importance lies in the following aspects:

During boiler operation, internal pressure-bearing components must endure high temperatures and high pressures for extended periods. By simulating or even exceeding normal operating pressures, hydraulic pressure testing effectively verifies the sufficient structural strength of core pressure-bearing components such as the steam drum, water walls, and superheater, ensuring they will not deform, rupture, or suffer serious problems under rated operating pressures and potential overpressure conditions.

Welds and flange joints are vulnerable points in boiler steam-water systems that are prone to leakage. During a hydraulic pressure test, water pressure can be used to visually detect leaks in these areas. Promptly identifying and addressing leaks can prevent energy waste, equipment damage, and even safety incidents caused by steam or high-temperature water leaks during operation.

During the manufacturing, transportation, and installation of boilers, hidden defects such as cracks, pinholes, incomplete welds, and misaligned edges may occur due to improper workmanship and operational errors. These defects are difficult to detect during routine inspections, but they become apparent through leakage and deformation under the pressure of a hydrostatic test, providing an opportunity to proactively address them and ensure the inherent safety of the equipment.

If a boiler is put into operation with potential defects, the continued high temperature and high pressure can rapidly expand, leading to serious accidents such as pipe bursts and explosions. These can not only cause expensive equipment damage but also pose a serious threat to the lives of on-site operators. Hydrostatic testing reduces operational risks at the source by proactively identifying potential hazards, effectively ensuring personnel safety and stable equipment operation.

According to the "Regulations on the Supervision of Boiler Vessels in the Power Industry" and other relevant regulations and standards, boiler hydrostatic testing is a mandatory safety inspection item. Whether newly installed or commissioned, a boiler must complete and pass a hydraulic pressure test in accordance with regulations before it can be put into service. This requirement is both essential for ensuring equipment safety and a fundamental prerequisite for compliance with production regulations.

Boiler hydraulic pressure tests are primarily categorized into the following two types based on the test pressure:

Rated Working Pressure Test

This test, conducted at the rated working pressure of the boiler, is primarily used for routine inspections to verify the boiler's tightness and structural stability under normal operating pressure. It is typically performed after minor or emergency repairs, or before re-ignition after a boiler has been shut down for more than 30 days.

Overpressure Test

The overpressure test pressure is higher than the rated working pressure of the boiler. The overpressure test pressure for the boiler proper (including the superheater) is 1.25 times the rated working pressure of the drum, and the overpressure test pressure for the reheater is 1.5 times the rated working pressure at the reheater inlet. This test is intended to more rigorously verify the strength of pressure components and identify potential structural defects.

Circumstances Requiring an Overpressure Hydrostatic Test

Before the start of trial operation for a newly installed boiler;

After major modifications (such as replacement of the steam drum or water-wall tube assembly) or replacement of pressure-bearing components of the boiler;

Operating boilers should undergo an overhaul every six years.

Circumstances Requiring a Working Pressure Hydrostatic Test

Generally, a hydrostatic test is required after major or minor overhauls or emergency repairs, or after the boiler has been overhauled.

A hydrostatic test must be performed before ignition for boilers that have been idle for more than 30 days.

Reheater system hydrostatic tests are not routinely conducted. In special circumstances, they must be proposed by the technical department and approved by the chief engineer.

Compliance with Regulations and Standards: Boiler hydrostatic tests must be conducted strictly in accordance with the relevant provisions of the "Regulations for the Supervision of Boiler Vessels in the Power Industry" to ensure that the test process and results meet industry safety standards.

Test Plan Approval: Before conducting a hydrostatic test, a detailed test plan and safety measures must be developed. The plan must be approved by the company's chief engineer before implementation. Unified Command and Dedicated Personnel: The test operation is under the unified command of the Operation Supervisor, who will clearly designate at least two individuals to control pressure and monitor pressure gauges to ensure compliance and safety.

The boiler hydraulic pressure test covers the main equipment and piping in the steam-water system, specifically divided into the following sections:

This includes the feedwater piping, economizer, steam drum, downcomer, water wall, superheater, main steam piping, as well as the headers and associated piping connecting these components. This circuit is the core pathway for generating and transporting main steam in the boiler and is the focus of the hydraulic pressure test inspection.

This covers the cold reheat piping (the piping from the turbine's high-pressure cylinder exhaust to the reheater), the reheater, the hot reheat piping (the piping from the reheater outlet to the turbine's intermediate-pressure cylinder), associated headers, and connecting piping. The tightness and strength of the reheater system directly impact the unit's thermal efficiency and is therefore a crucial component of the test.

All exhaust pipes, drain pipes, instrument pipes, and chemical dosing pipes connected to the boiler's steam-water system must be hydrostatically tested up to the secondary valves on these pipes to ensure the tightness of the branch pipe connections to the main system.

The drum water level gauge and safety valve are only tested at the rated working pressure and not at the overpressure test. This is because the design pressure of the water level gauge and safety valve is typically matched to the rated working pressure of the boiler. Overpressure testing may damage their internal structure and affect their proper function.

Adequate pre-test and preparation are crucial to ensuring a smooth hydrostatic test. Specific tasks are as follows:

Confirm that all steam-water system maintenance work related to the boiler hydrostatic test has been completed, the work permit has been issued, and no personnel are working in the furnace, tail flue, or other confined spaces to avoid safety accidents during the test.

Clearly define the division of responsibilities among test participants and ensure that relevant personnel, such as those responsible for operations, maintenance, and chemistry, are in place and familiar with the test plan and emergency procedures.

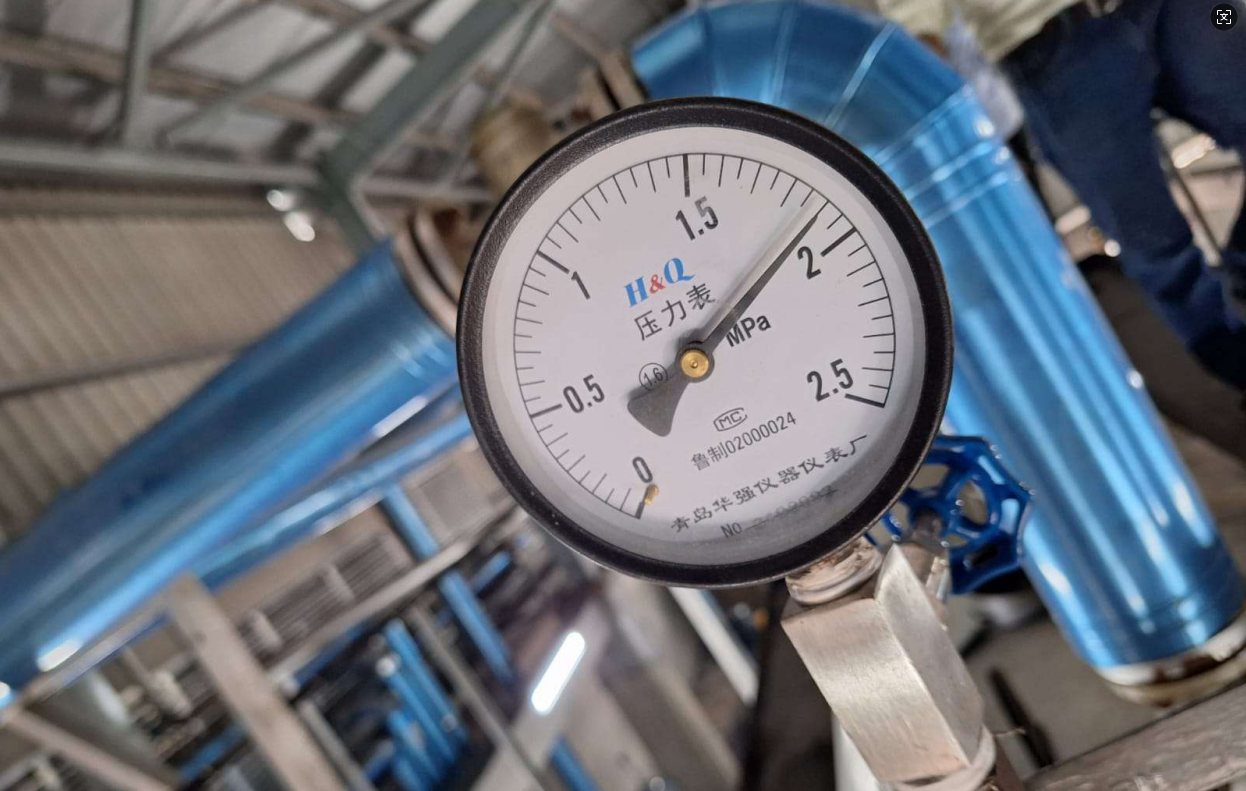

Install standard pressure gauges at the drum and reheater inlets. The pressure gauges must meet a Class 0.5 accuracy rating or higher, with a range of no less than 40 MPa. A minimum of two gauges should be installed to ensure accurate pressure monitoring.

All pressure gauges in use (including those located on-site and in the central control room, and superheater outlet pressure gauges, etc.) should be calibrated. Thermal engineers should ensure that the readings of the central control room pressure gauges are consistent with those of the local standard pressure gauges.

Ensure smooth communication between the on-site test site and the central control room. Equip reliable communication tools (such as walkie-talkies) to facilitate command and information feedback during the test.

Connect the drum emergency drain valve to the power supply and check its open and close function. Ensure the drain pipe is clear. Prepare for potential accidents during the pressure increase process and clearly define emergency procedures for overpressure and other emergencies.

Implement reliable isolation measures, such as closing the main steam valve and reheat steam valve on the turbine side and opening relevant drain valves, to prevent water from entering the turbine during the hydrostatic test, potentially causing serious consequences such as damage to turbine blades.

The water used for the hydrostatic test must be refined demineralized water. The water quality must meet the test plan requirements, and the water temperature must be controlled between 30–50°C. The appropriate water temperature avoids excessive thermal stress in boiler pressure components due to large temperature differences and prevents impurities in the water from clogging pipes and affecting test results.

Completely check the correct position of all relevant valves to ensure that the isolation and conduction of the test system meet the plan requirements. Set the superheater solenoid pressure relief valve control switch to the closed position.

Contact maintenance personnel to temporarily secure all constant force hangers on the main steam and reheat steam lines and the spring hangers in the top stop with latches or spacers (remove after the test) to prevent the hangers from overloading and failing due to the test pressure.

After completing pre-test inspections and preparations, report to the test leader and shift supervisor. After obtaining the shift supervisor's approval, start the feedwater pump and begin water filling. The water filling process must strictly follow the instructions in the start-up preparations.

When the water level reaches the visible level in the steam drum (usually -100mm), stop filling. Then, open the superheater's secondary desuperheating water electric shutoff valve and adjust the secondary desuperheating water regulating valve to reverse the flow of water back into the boiler.

During the water filling process, proceed slowly while simultaneously opening the air valves in various locations on the boiler to ensure sufficient air is exhausted from the system. If water continuously overflows from each air valve, close each air valve in the order indicated by the water flow and suspend water filling.

After receiving the pressure increase command, slowly increase the pressure by operating the secondary desuperheating water regulating valve. The initial pressure increase rate should not exceed 0.3 MPa/min. When the pressure reaches 10 MPa, reduce the pressure increase rate to no more than 0.2 MPa/min to avoid excessive shock to pressure-bearing components caused by excessive pressure increase.

When the pressure reaches approximately 10% of the safety valve's minimum set pressure (drum pressure approximately 2 MPa, reheater pressure approximately 0.43 MPa), pause the pressure increase, verify the consistency of the primary and secondary drum pressure gauges, and conduct a preliminary system inspection. Pressure increase may only be continued if no leakage or other abnormalities are found.

When the pressure continues to increase to approximately 80% of the safety valve's minimum set pressure (drum pressure approximately 15.8 MPa, reheater pressure approximately 3.5 MPa), pause the pressure increase again and maintain the pressure stable. Notify maintenance personnel to install a hold-down device on the safety valve to prevent malfunction before the overpressure test.

Maintaining Pressure at Operating Pressure

When the pressure reaches the rated operating pressure of the boiler, close the water inlet valve and maintain the pressure for 5 minutes. Record the pressure drop during this period. Then, slightly open the water inlet valve to maintain a stable operating pressure. Organize personnel to conduct a comprehensive inspection of the boiler's pressure-bearing components, welds, flange connections, and other areas to check for leaks.

Maintaining and Reducing Pressure During Overpressure Test

If an overpressure test is necessary, after the operating pressure has been verified to be normal, first disconnect the drum water level gauge and slowly increase the pressure to the overpressure test pressure. Once the specified pressure is reached, maintain the pressure for 5 minutes. Then, close the water inlet valve, open the economizer inlet header drain valve, and slowly reduce the pressure at a rate of 0.2-0.3 MPa per minute.

When the pressure drops to the rated operating pressure, close the drain valve to stop the pressure reduction. Record the pressure drop over 5 minutes. Then, slightly open the water inlet valve to maintain the operating pressure. Perform a second comprehensive system inspection.

After the hydrostatic test, use the system drain valve or cascade regulating valve to release the pressure. Control the release rate to 0.2-0.3 MPa/min to avoid excessively rapid release, which could lead to negative pressure or water shock in the system.

When the drum pressure drops to 15.8 MPa and the reheater pressure drops to 3.5 MPa, release the pressure relief device on the safety valve and continue to slowly reduce the pressure.

When the system pressure drops to 0.2 MPa, open all air valves to release the pressure. After the pressure drops to 0 MPa, open all drain valves to drain the water and restore the drum water level gauge.

If the boiler is to be put into operation immediately after the hydrostatic test and the water quality meets the requirements, the water level can be lowered to the ignition level, and the superheater, main steam piping, and reheater must be drained. If the boiler is not to be put into operation immediately, drain all water from the system and refill it with water before subsequent commissioning.

A boiler's hydrostatic test must meet the following criteria to be considered qualified:

During the rated operating pressure maintenance period, the pressure drop in the boiler body shall not exceed 0.1 MPa/min, and the pressure drop in the reheat system shall not exceed 0.05 MPa/min, indicating good system tightness.

Carefully inspect all pressure-bearing components of the boiler, including metal walls, welds, and flange connections, for any signs of leakage, such as water droplets or mist, and for any visible leakage.

After the test, inspect the boiler's pressure-bearing components (such as the steam drum, header, and water-wall tubes) for any obvious residual deformation by observing expansion indicators and other methods to ensure that their structural strength meets operational requirements.

The hydrostatic test shall be presided over by the maintenance manager, with participation from both operation and maintenance personnel, ensuring clear responsibilities. In the event of an abnormal situation or malfunction, the operation personnel must promptly address the situation in strict accordance with procedures and relevant regulations.

Strictly adhere to the "low pressure first, high pressure later" testing principle. Conduct the hydrostatic test on the reheater system first, and only after passing the test on the boiler body and superheater system. Gradually increase the pressure to minimize risk.

Before and after filling the boiler with water, record the expansion indicator readings to analyze whether the expansion of the boiler's pressure-bearing components is normal to avoid excessive stress caused by uneven expansion.

Adjust the water inlet evenly and slowly, and avoid abrupt opening and closing of valves to prevent sudden changes in water flow velocity that could cause water shock and damage piping and equipment.

During the test, ensure that all boiler metal and water temperatures are at least 21°C, with the water temperature maintained between 30°C and 50°C to prevent cracks in components caused by large temperature differences.

The boiler water inflow rate should be kept constant and should be maintained at a moderate rate. The water inflow time should be no less than 4 hours in winter and no less than 2-3 hours in other seasons. When the inlet water temperature approaches the drum wall temperature, the water inflow rate may be increased appropriately.

During the overpressure test, system inspections are strictly prohibited, and all personnel must stay away from pressure-bearing components. Inspections may only be conducted near the equipment after the pressure has dropped to the rated operating pressure.

The hydrostatic test pressure should be based on the reading of a precision pressure gauge located on-site at the drum or reheater inlet to ensure accurate pressure monitoring and prevent overpressure.

The water used in the hydrostatic test is highly alkaline. When discharging the test water, operators must take protective measures (such as wearing protective gloves and goggles) and properly dispose of the discharged water to avoid environmental contamination.

A dedicated person should maintain detailed records throughout the test, including test time, pressure values at each stage, pressure changes, any issues discovered during the inspection, and any corrective measures. This will provide a basis for subsequent equipment operation and maintenance. Before increasing the pressure, it's important to anticipate potential accidents. If an emergency situation, such as a feedwater pump or throttle valve failure, leads to overpressure, pressure relief measures should be implemented sequentially, including opening the superheater header drain valve, the drum emergency drain valve, the continuous or fixed drain valves, and emergency stopping the feedwater pump.

Boiler hydraulic pressure testing, a critical step in ensuring safe boiler operation, is not only a core means of verifying the structural strength and tightness of the equipment but also a necessary measure for identifying potential defects, mitigating operational risks, and meeting regulatory standards. Its strict implementation directly determines the boiler's ability to achieve long-term, stable, and safe operation, and is crucial for ensuring the continuity of power plant and industrial production and the safety of personnel.

To maximize the effectiveness of hydraulic pressure testing, relevant companies and technicians must strictly follow test requirements, step-by-step procedures, and safety regulations to ensure a standardized test process and reliable results. At the same time, it is recommended to combine water pressure testing with regular inspection and scientific operation and maintenance of boilers. Through daily status monitoring and maintenance, equipment problems can be discovered and handled in a timely manner to maximize the service life of boiler equipment and lay a solid foundation for the efficient and safe operation of the production system.