Industrial burners are key components in thermal systems and energy production. Their core function is to convert a wide range of fuels, such as natural gas, fuel oil, and industrial waste gases, into heat energy through combustion. Widely used in refineries, chemical plants, power plants and centralized heating systems, this type of equipment is not only the “heart” of the heat supply, but also a direct influence on energy efficiency and operating costs.

Efficiency Driven: Efficient combustion maximizes heat output and avoids fuel waste;

Cost Control: Reduced energy consumption directly reduces operating expenses, with a typical 3% efficiency improvement resulting in annual six-figure cost savings;

Environmental Responsibility: Modern burners are designed with the core objective of reducing NOx, CO and other pollutant emissions, in line with global environmental standards.

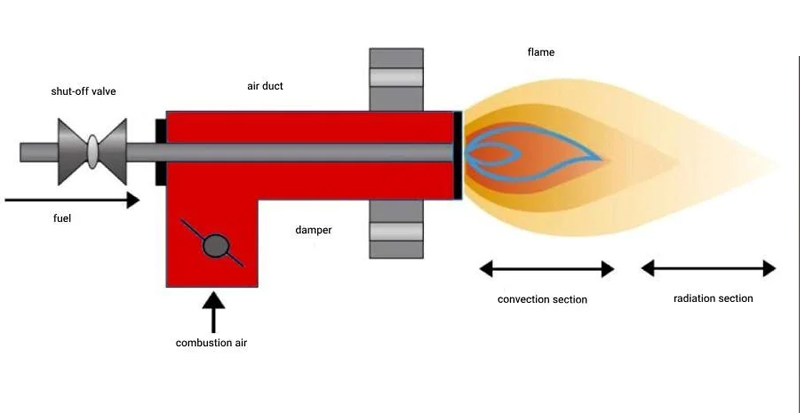

Air Supply System: The air required for combustion is delivered through fans and motors. Precise control of the air-fuel ratio is the basis for efficient combustion;

Fuel Injection: The gaseous fuel is fed directly into the combustion chamber in a gaseous state, while the liquid fuel (e.g. heavy oil) is atomized into fine droplets by pumps and nozzles;

Fuel-Air Mixing: Homogeneous mixing is accomplished in the combustion chamber - the gaseous fuel is mixed with the air through ducted nozzles, and the liquid fuel is atomized to achieve full contact;

Ignition And Combustion: the combustion process is initiated by an ignition electrode or pilot burner, which forms a stable flame and releases heat energy;

Intelligent Control: real-time monitoring of temperature, pressure and other parameters through sensors, automatically adjusting the operating status to ensure efficiency and safety;

Flue Gas Emission: The carbon dioxide, water vapor and other flue gases generated by combustion are discharged through the chimney or exhaust system.

Gas Fuel Chain: Contains filters, regulators, safety valves, pressure sensors, etc. to ensure a stable supply of gas;

Liquid Fuel Chain: consists of oil pumps, solenoid valves, fuel regulators, providing pressure guarantee for atomized combustion.

Gas Nozzle: precisely control the gas injection direction and mixing angle;

Liquid Nozzle: atomize the fuel into micron-sized droplets to expand the contact area with air.

Blower: Provides the forced air flow required for combustion, the power is customized according to the burner specifications;

Dampers: manually or automatically adjust the airflow to optimize the air-fuel ratio in real time;

Duct: in dual block burners, connects the fan to the burner body.

Pilot small flame: the”start key”for large burners, igniting before the main fuel to ensure safety;

Flame detection device: continuous monitoring of the flame status and immediate cut-off of the fuel supply in case of abnormality;

Emergency shutdown system: automatically triggered shutdown in case of pressure overrun or sensor failure to prevent the accident from expanding.

Gas burners: Fueled by natural gas, propane, hydrogen or industrial waste gas, low maintenance costs and high combustion efficiency;

Oil burners: for liquid fuels such as diesel, heavy oil, etc., flexible but need to pay attention to the atomization effect;

Dual-fuel burners: can be switched between gas and oil or used simultaneously to cope with fluctuations in fuel supply.

Diffusion burner: direct mixing of fuel and air at the combustion point, simple structure but sloppy flame control;

Pre-mixed burner: Fuel and air are pre-mixed before combustion to achieve flame uniformity and precise temperature control;

Low-NOx/Ultra-low-NOx burner: through staged combustion, flue gas recirculation (FGR) and other technologies, NOx emissions are controlled to below 30mg/m³ to meet the stringent environmental regulations.

Capacity and Turndown Ratio (Turndown Ratio) need to match the maximum heat load of the boiler (BTU/hr), too small will lead to insufficient output, while too large will lead to frequent startups and shutdowns;

High turndown ratios (e.g. 10:1) are suitable for scenarios with large load fluctuations (e.g. food processing), but need to balance stability and cost.

Single-fuel burners are less expensive, and dual-fuel designs can be used as a backup;

Liquid fuels require attention to atomization methods (e.g., pressure atomization, air atomization), which affect combustion completeness.

Clearly defined local NOx and CO emission limits (e.g. EU EN 15502);

Ultra-low-NOx burners can avoid environmental fines and equipment retrofit costs in the long term, although the initial investment is high.

Linkageless control and Oxygen Trim system for improved combustion accuracy;

Variable Frequency Drives (VFDs) reduce power consumption and enable dynamic load matching.

Initial investment is only 30% of the total cost and needs to be evaluated:

Annual fuel consumption (1% difference in efficiency can result in a difference of tens of thousands of cubic meters of gas per year);

Maintenance frequency (e.g. FGR system for low NOx burners needs to be cleaned regularly);

Upgrade potential (e.g. whether a future conversion to hydrogen is supported).

Refineries: Burners for heating furnaces to handle crude oil distillation, need to withstand high temperatures and frequent load adjustments;

Power plants: pulverized coal burners and gas turbine burners to drive steam generation, ultra-low nitrogen design as standard;

Coal chemical plants: gasifier burners convert coal into syngas, requiring high reliability and long life.

Metal smelting: blast furnace burners melt steel, glass kiln burners control the melting temperature;

Food processing: small burners for baking ovens and sterilization equipment, requiring temperature uniformity and hygienic design;

Automotive manufacturing: burners for drying ovens in coating lines, combined with exhaust gas incineration systems to realize VOCs treatment.

Waste incineration: multi-fuel burners for mixed waste, to cope with fluctuations in calorific value;

Ship power: Marine burners are adapted to heavy fuel oil to meet International Maritime Organization (IMO) emission requirements;

Building heating: burners for district heating stations, pursuing high load factors and seasonal adjustability.

Real-time optimization: monitoring of combustion parameters via PLC or cloud platform, automatic correction of air-fuel ratio;

Predictive maintenance: Sensor data combined with AI algorithms provide early warning of component failures (e.g., clogged nozzles);

Case: After upgrading the smart burner in a chemical company, energy consumption dropped by 12% and downtime was reduced by 80%.

Hydrogen combustion: some burners have realized 100% hydrogen doping, zero carbon emission;

Flue gas recirculation (FGR): part of the flue gas is sent back to the combustion chamber to lower the combustion temperature to inhibit NOx generation;

Electro-thermal coupling: Combined with heat pump technology, the combustion is assisted by electricity during low power hours to reduce fuel consumption.

Monthly Inspection: Clean the combustion head of carbon deposits, test the ignition electrode spacing;

Quarterly maintenance: calibration of pressure sensors, checking the sealing of the fuel manifold;

Annual overhaul: replacing worn parts (e.g. blower bearings) and fully commissioning the control system.

Pre-ignition purge: 5-10 minutes of forced ventilation before start-up to prevent deflagration;

Flame monitoring: each burner should be equipped with an independent flame detector (e.g. ultraviolet photosensitive tube);

Personnel training: operators need to master the emergency shutdown procedures and common troubleshooting (e.g., “no fire” when checking fuel pressure and ignition energy).

The selection of industrial burners is not a simple equipment purchase, but a systematic project involving energy strategy, environmental compliance and cost control. For retrofitting of existing equipment, it is recommended to prioritize the evaluation of

Combustion efficiency (determine the excess air factor through flue gas analysis);

Emission levels (whether they are facing upgrades to local environmental standards);

Operating hours (high load equipment is prioritized for retrofitting for quick cost recovery).

In the future, with the development of hydrogen economy and carbon capture technology, the burner will evolve to “zero carbon combustion”direction. Enterprises need to layout in advance, selecting products with fuel adaptability and technology upgrade potential, to reduce operating costs while laying the foundation for green transformation.