Boilers play an indispensable and central role in numerous industrial processes. Like the "heart" of the industrial system, they generate heat energy from fuel combustion, heating water into steam or hot water. This provides a continuous source of power and energy for numerous sectors, including power generation, chemical engineering, metallurgy, and heating. They are crucial equipment for ensuring stable industrial operations.

However, over long-term operation, boilers are prone to ash buildup on their heating surfaces. Fly ash produced by fuel combustion gradually adheres to heating surfaces such as the furnace, superheater, economizer, and air preheater. If not promptly addressed, this problem can lead to a series of serious hazards, not only affecting the boiler's normal operating efficiency but also creating safety hazards and increasing operating costs.

To effectively address ash buildup, boiler soot blowers (soot blowers) have emerged. As crucial auxiliary equipment, they can effectively remove ash from heating surfaces, becoming a key solution to the problem of boiler ash buildup.

Soot buildup significantly impacts boiler efficiency. Ash accumulation acts like a thick layer of insulation covering the boiler's heating surfaces, severely hindering heat transfer. Heat energy that could otherwise be efficiently transferred to the working fluid is lost due to ash accumulation, preventing the boiler from fully utilizing the heat generated by fuel combustion. To achieve the desired output parameters, the boiler must consume more fuel, resulting in a significant increase in fuel consumption and a significant decrease in operating efficiency.

Ash accumulation not only affects efficiency but also poses serious safety risks. Ash accumulation often contains incompletely burned combustibles, which, under high temperatures, can reignite and easily cause furnace fires. Ash accumulation is a particularly prominent problem in certain types of boilers, such as black liquor recovery boilers. Ash accumulation from black liquor combustion is highly viscous and flammable. Excessive ash accumulation, under the right conditions, can cause a violent explosion, posing a significant threat to equipment and personnel safety.

Long-term ash accumulation can lead to overheating of boiler tubes. Because ash accumulation hinders heat transfer, heat from the tube surface cannot be removed promptly, causing the temperature to continue to rise. Excessively high temperatures significantly reduce the strength of the furnace tube metal, degrading material properties and making it prone to deformation, bulging, and even rupture. This not only affects the normal operation of the boiler but also significantly shortens its service life and increases equipment replacement costs.

To remove ash deposits and repair damaged equipment, the boiler must be shut down. During this downtime, industrial production processes are interrupted, preventing normal production, resulting in direct production losses. Furthermore, cleaning ash deposits and repairing equipment requires significant manpower, material resources, and time, further increasing operating costs. Frequent downtime also impacts production plans and delivery cycles, negatively impacting the company's economic performance and market reputation.

A boiler soot blower is a specialized auxiliary device designed for boilers. Its core function is to remove impurities such as fly ash and slag from the boiler's heating surfaces, ensuring their cleanliness.

It primarily operates by using a medium such as high-pressure steam, compressed air, or water, sprayed at high speed through a specific nozzle to flush the boiler's heating surface. The high-speed flow of the medium creates a powerful impact force, dislodging and removing accumulated soot from the heating surface, thereby restoring its heat transfer performance.

The main functions of a boiler soot blower are crucial. First, it effectively improves the heat transfer efficiency of the heating surface, reduces heat loss, and lowers fuel consumption. Second, by removing soot deposits, it avoids safety hazards such as fire and explosion caused by soot accumulation, ensuring safe and stable boiler operation. Furthermore, it reduces corrosion and damage to equipment caused by soot accumulation, extending the boiler's service life.

Wall-type soot blowers have a relatively simple structure. Their design features a nozzle that can be extended into a specific area within the boiler. They are typically installed on the walls of heating surfaces such as the boiler furnace water walls and superheaters, allowing them to directly blow soot from heating surfaces close to the furnace wall.

This type of soot blower is particularly suitable for use in localized high-temperature areas of the boiler, such as furnace corners, where soot accumulation and high temperatures are common. In terms of advantages, wall-mounted soot blowers offer a simple structure, low manufacturing costs, and are relatively easy to install and maintain. However, they also have limitations. Due to the limited reach of their nozzles, the sootblowing coverage area is small, effectively cleaning only localized areas and ineffectively cleaning large heating surfaces.

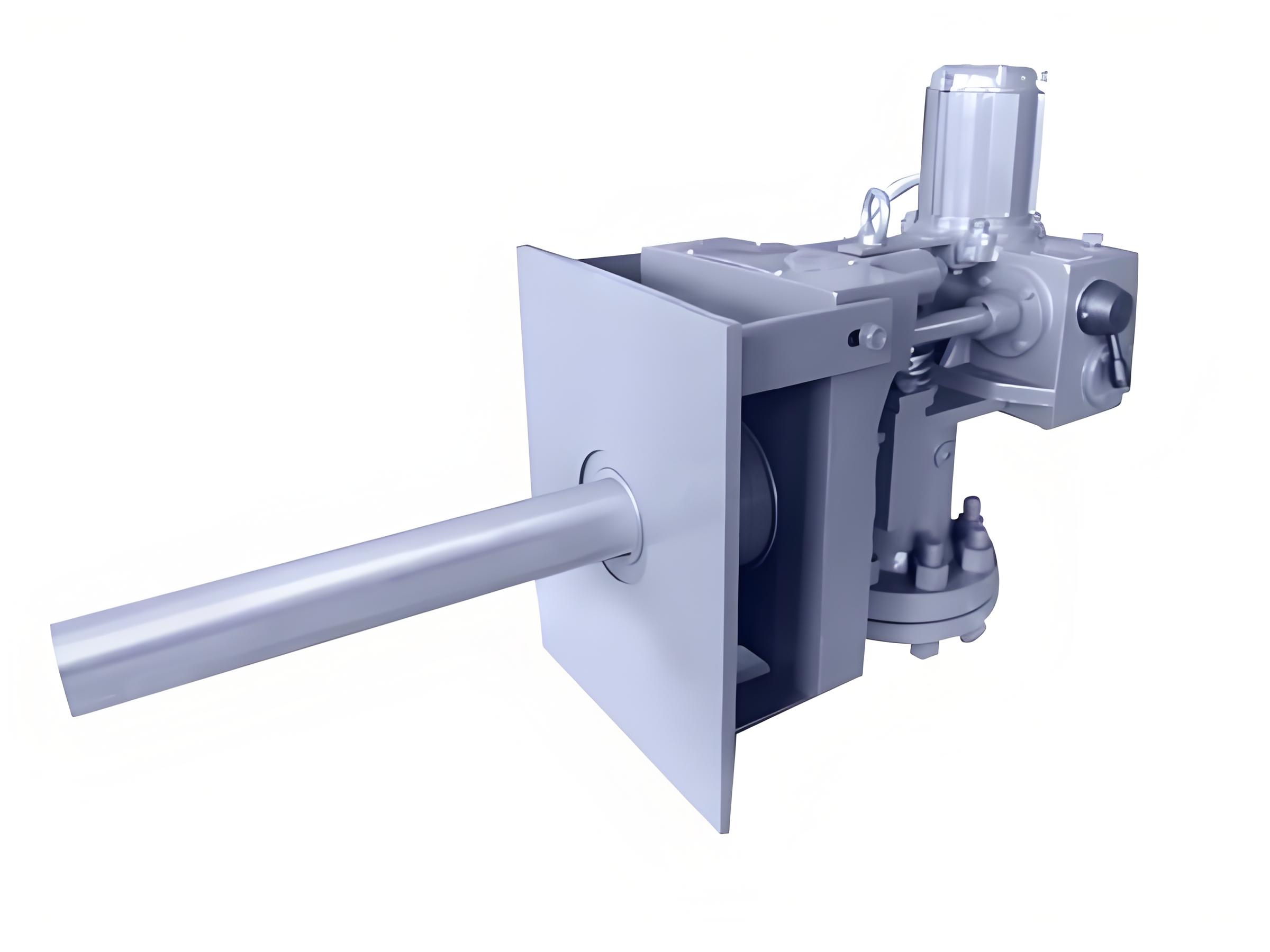

The long retractable soot blower is equipped with a long, retractable barrel. During operation, the barrel can penetrate deep into the boiler interior and rotate 360°, allowing the rotating nozzle to comprehensively clean the heating surfaces.

This design allows it to cover a large area, making it particularly effective for cleaning soot deposits on large heating surfaces within the boiler, such as superheaters and reheaters. It is also suitable for operating in high-temperature environments.

However, this type of sootblower is relatively expensive due to its complex structure, involving precision mechanical components such as telescopic and rotating components. However, in terms of cleaning effectiveness, it performs best among all sootblower types, effectively removing soot deposits from large areas.

An air preheater soot blower is a specialized soot-blowing device designed specifically for air preheaters. During operation, condensed water in the flue gas combines with dust to form scale on the low-temperature side of the air preheater, affecting the heat exchange efficiency and proper operation of the air preheater.

Air preheater soot blowers can effectively address this problem. They are primarily available in two types: telescopic and swing-arm. Telescopic soot blowers use a retractable barrel to penetrate deep into the air preheater to blow soot; swing-arm soot blowers use the swinging arm to drive the nozzle to clean the heating surface.

A rotary soot blower is fixedly installed inside the boiler. Its characteristic structure is that it is equipped with multiple nozzles, which rotate during operation to blow soot from the heating surface.

Due to its structural design and temperature resistance limitations, it is not suitable for use in the high-temperature areas of the boiler. Instead, it is more suitable for relatively low-temperature heating surfaces such as economizers and air preheaters. This sootblower has a compact structure and occupies a small space inside the boiler. It can achieve effective sootblowing operations in a limited space, saving installation space inside the boiler.

To provide a clearer comparison of the characteristics of various soot blowers, their advantages and disadvantages are presented in the table below:

|

SootBlowerType |

Advantages |

Disadvantages |

|

Rotary |

Space-saving, compact structure, requires minimal installation space; easy maintenance, relatively simple mechanical structure, low daily maintenance workload |

Limited cleaning range; due to fixed installation and restricted rotation angle, it cannot comprehensively clean large heating surfaces |

|

Retractable |

Wide coverage, designed to retract and rotate, enabling cleaning of large heating surfaces; effective cleaning, capable of removing various types of ash deposits |

Complex installation, involves precise retraction and rotation mechanisms, making installation difficult; high cost, both in manufacturing and installation |

|

Wall / Fixed |

Suitable for local high-temperature points, can adapt to localized ash cleaning in high-temperature environments; low cost, inexpensive to manufacture and maintain |

Limited coverage, can only clean localized areas near the installation point, unable to meet large-scale cleaning requirements |

Boiler soot blowers effectively prevent a decrease in boiler thermal efficiency by promptly removing soot accumulation from heating surfaces. Maintaining a clean heating surface ensures efficient heat transfer to the working fluid, thereby reducing fuel waste, achieving fuel savings, and improving boiler operating efficiency.

Soot accumulation can lead to overheating and corrosion of furnace tubes and heating surfaces. Regular cleaning of soot blowers prevents these problems. Soot blowers protect the tubes and heating surfaces from damage, reducing equipment failures and damage caused by soot accumulation, thereby extending the overall service life of boiler equipment and reducing the frequency and cost of equipment replacement.

Soot blowers promptly remove combustibles from accumulated soot, preventing them from igniting at high temperatures and causing furnace fires. They also prevent pressure abnormalities caused by excessive soot accumulation, fundamentally reducing explosion hazards and ensuring safe and stable boiler operation and the personal safety of operators.

Regularly using soot blowers to clean accumulated soot can reduce the need for large-scale cleaning operations due to severe soot accumulation, minimizing production losses caused by downtime. It also reduces the workload and cost of manual soot cleaning, lowering the frequency and expense of equipment maintenance, and ultimately lowering your company's operating costs.

Selecting the right boiler soot blower requires comprehensive consideration of several key factors to ensure it meets the actual operating requirements of your boiler.

First, boiler type and structure. Different types of boilers, such as power plant boilers, industrial boilers, and waste heat boilers, have significantly different internal structures and heating surface arrangements, necessitating different soot blower types. The selection should be based on the specific boiler type and structural characteristics.

Second, the location of the soot to be cleaned. Different boiler areas, such as the furnace, air preheater, economizer, and superheater, experience varying characteristics and levels of soot accumulation, placing varying demands on the soot blower. For example, if the furnace temperature is high and the soot deposits are thick, a sootblower that can withstand high temperatures and has strong cleaning capabilities is needed. Meanwhile, a dedicated sootblower is needed to handle the low-temperature fouling problem at the air preheater.

The temperature environment is also a key consideration. Different sootblowers have their applicable temperature ranges. You need to select a sootblower that can operate stably within these temperature ranges, based on the actual temperature conditions of each part of the boiler, to ensure its service life and performance.

Space and installation conditions are also important considerations. Internal boiler space is limited, and different types of sootblower require different installation space requirements. Consider factors such as internal boiler space and accessibility to the installation location to select a sootblower with appropriate dimensions and installation method.

Finally, budget and maintenance costs are important. Different types of sootblower vary in purchase, installation, and ongoing maintenance costs. Companies should choose a cost-effective sootblower that meets their specific needs and budget, while also considering long-term maintenance costs.

Based on these factors, it is recommended that companies work with a professional boiler sootblower manufacturer when selecting a sootblower. Professional manufacturers can provide customized solutions based on the specific parameters, operating conditions, and actual needs of your boiler, helping you select the most suitable sootblower.

Boiler sootblowers play a vital role in boiler operation. They not only effectively remove soot deposits from heating surfaces, improving heat transfer efficiency and reducing energy consumption, but also ensure safe and stable operation, reduce safety incidents, and extend the service life of boiler equipment. They are key equipment for improving boiler efficiency, ensuring safety, and extending boiler life.

Choosing the right sootblower is of great significance to your business. The right sootblower can maximize its soot removal effectiveness, bringing long-term energy savings, reducing fuel consumption and operating costs, while also minimizing equipment failures and downtime, improving production efficiency, and ultimately creating significant economic benefits for your business.

If your business is struggling with boiler soot accumulation or needs to select the right sootblower for your boiler, contact a professional boiler and sootblower supplier immediately. They have extensive experience and expertise, and can provide customized solutions to help you achieve efficient, safe, and economical boiler operation.