In today's heating and industrial sectors, natural gas burners have become indispensable core equipment due to their significant advantages in efficiency, cost-effectiveness, and environmental friendliness. Whether providing a warm and comfortable living environment for homes or providing continuous and stable heat support for industrial production, natural gas burners play a vital role.

A natural gas burner is a specially designed device that mixes natural gas with the required combustion air and burns it, producing a stable and controllable flame to provide the necessary heat or energy for various systems. Its design is primarily focused on achieving efficient natural gas combustion to meet heating needs in diverse scenarios.

While the basic operating principles of natural gas burners are similar to those of burners using other gaseous fuels, such as liquefied petroleum gas (LPG), they are tailored to the unique physical and chemical properties of natural gas. Natural gas has specific characteristics such as calorific value and combustion rate. Natural gas burners are optimized in terms of structural design and air-fuel ratio control to ensure full combustion and optimal efficiency.

After receiving gas from the natural gas pipeline, a natural gas burner precisely regulates the gas pressure through a pressure regulator. This step is crucial. Only by ensuring that the gas enters the burner at the appropriate pressure can we ensure stable combustion and avoid pressure fluctuations that can affect combustion.

The fan or blower in the burner is responsible for providing combustion air and precisely controlling the air-gas mixture ratio. The proper air-fuel ratio directly determines the efficiency and cleanliness of combustion. An inappropriate mixture can result in incomplete combustion, wasting fuel and increasing pollutant emissions.

The thoroughly mixed air and gas are delivered to the combustion chamber. The combustion chamber is constructed of high-temperature resistant materials with good thermal insulation properties, providing a suitable space and environment for gas combustion. Within the combustion chamber, the gas and air undergo a vigorous chemical reaction, generating a large amount of heat energy and forming a stable flame.

The ignition system is a key component for initiating the combustion process. It generates ignition energy through methods such as an electric spark or a hot surface, igniting the air-fuel mixture. At the same time, the ignition system must ensure that the flame burns continuously and stably, guaranteeing the safety and continuity of the combustion process.

The high-temperature flue gases generated by combustion are directed to the heat exchanger, where the heat in the flue gases is transferred to the water or air flowing through the heat exchanger through heat conduction and convection. This heated water or air is then transported through the heating system to various locations where heat is needed, achieving efficient utilization of the heat energy.

The exhaust gases generated during the combustion process are discharged through a chimney or exhaust system. To reduce environmental pollution, these exhaust gases are filtered and purified before discharge to remove harmful substances and ensure they meet environmental emission standards.

One of the most prominent features of natural gas burners is their ability to precisely control the fuel-air mixture. This precise adjustment of the air-fuel ratio ensures full combustion of natural gas, significantly improving energy efficiency and reducing fuel consumption. It also effectively reduces emissions of pollutants such as carbon monoxide (CO) and nitrogen oxides (NOx), complying with environmental protection requirements.

To ensure safety during use, natural gas burners are equipped with a series of advanced safety systems. These include flame sensors that monitor the flame status in real time and immediately issue signals if they detect abnormal flame extinguishing. Gas pressure sensors monitor changes in gas pressure to ensure a stable gas supply. These safety devices automatically shut off the gas supply upon detecting a fault, preventing accidents such as gas leaks and explosions.

Many natural gas burners feature continuous capacity adjustment (modulation) systems, allowing users to flexibly adjust heat output between minimum and maximum capacity based on actual heat demand. This feature not only improves temperature control accuracy and ensures more stable temperatures in indoor or production environments, but also significantly saves fuel and reduces energy costs.

Because natural gas burners utilize an optimized combustion design that ensures complete combustion of natural gas, pollutant emissions are relatively low. This makes natural gas burners environmentally friendly heating and cooling equipment, helping to reduce environmental damage and meet increasingly stringent environmental regulations.

Natural gas burners have a wide range of applications. In residential applications, they can be used for home heating and domestic hot water supply; in industrial applications, they can be used in various industrial furnaces, boilers, power generation equipment, and heating processes in production processes. Their strong adaptability stems from their ability to precisely adjust heat output to meet diverse heat requirements in different scenarios.

Natural gas burners must be installed by authorized professional service providers. These professionals possess extensive experience and expertise, ensuring that the burner installation process complies with relevant technical specifications and safety standards, and that the burner is properly commissioned and tested to ensure its subsequent safe and stable operation.

When selecting a natural gas burner, ensure that its model matches the capacity of the heating system. Over-capacity burners waste energy, while under-capacity burners cannot meet heating needs, impacting system operation. Therefore, accurately matching the model is essential for ensuring efficient burner operation.

The burner must be accurately connected to the heating system's combustion chamber. The size and shape of the combustion chamber must be compatible with the burner, and sufficient air intake and proper exhaust venting must be ensured to ensure smooth combustion.

Electrical connections must strictly comply with the burner's technical specifications and local electrical regulations. Ensure proper grounding and installation of appropriate fuses during connection to prevent electrical short circuits, leakage, and other accidents, ensuring the safety of equipment and personnel.

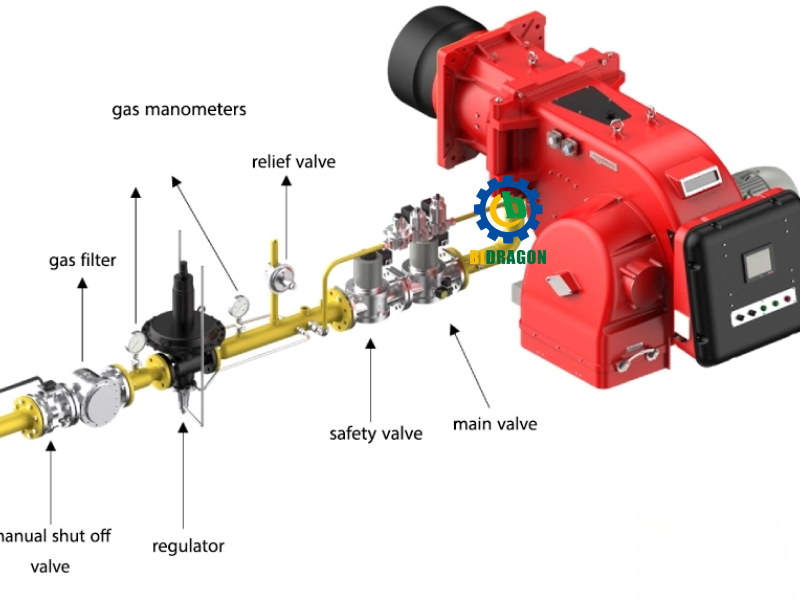

The gas connection must comply with the burner's technical requirements and local gas regulations. Safety control components such as gas valves, gas filters, gas pressure regulators, and gas pressure switches must be installed in the gas connection line to ensure a safe and stable gas supply.

Depending on the burner type, the air-fuel mixture ratio must be properly adjusted. Single-stage, two-stage, or modulating adjustment methods can be used. A proper air-fuel mixture ratio ensures efficient and clean combustion, improving burner performance.

The initial startup of the burner must be performed by a professional staff member of an authorized service agency. During the initial startup, the burner's ignition system, flame detection system, safety system, and various combustion parameters must be thoroughly tested to ensure proper and safe operation.

The primary function of the fuel supply system is to provide the burner with a continuous, stable, and clean supply of natural gas. This system includes components such as the gas valve, gas filter, and gas pressure regulator. The gas valve controls the flow of gas, the gas filter removes impurities from the gas, and the gas pressure regulator ensures that the gas enters the burner at the appropriate pressure.

The combustion chamber is where the gas and air mix and the combustion reaction occurs. Its design is carefully optimized to ensure complete combustion of the gas, maximize heat transfer efficiency, and minimize heat loss and pollutant emissions. The combustion chamber material has excellent high-temperature resistance to withstand the high temperatures encountered during the combustion process.

Both residential and industrial natural gas burners require an ignition system to initiate the combustion process. Common ignition methods include spark ignition, pilot burner ignition, and hot surface ignition. These ignition methods provide sufficient energy to ignite the air-fuel mixture and initiate the combustion process.

Modern natural gas burners are equipped with advanced control systems that precisely modulate heat output, ensuring the burner operates at optimal conditions and improving energy efficiency. At the same time, safety features such as flame monitoring systems and pressure sensors monitor burner operating parameters in real time. Once an abnormality is detected, appropriate protective measures can be immediately implemented to prevent accidents.

Selecting a natural gas burner that matches the capacity of your heating system and properly adjusting it ensures that the burner always operates at optimal performance. Proper parameter settings improve combustion efficiency, reduce fuel waste, and thus lower energy costs.

Proper selection and adjustment, combined with regular maintenance, can effectively prevent safety risks caused by burner failure. Improper burner selection or improper adjustment can lead to gas leaks and incomplete combustion, seriously threatening the safety of personnel and equipment.

Properly selected and adjusted natural gas burners are more likely to meet environmental regulations for pollutant emissions. With growing environmental awareness, complying with regulatory requirements not only avoids penalties for violations but also fosters a positive environmental image, especially in the industrial sector.

When a natural gas burner is appropriately modeled and properly adjusted, the wear and stress on the equipment during operation are significantly reduced, thereby extending its service life. This not only reduces the frequency of equipment replacement but also reduces maintenance costs, saving users money.

In the civilian sector, natural gas burners are primarily used for home heating and domestic hot water supply. They provide a stable and comfortable warm environment while meeting the daily hot water needs of family members, improving the quality of family life.

In the industrial sector, natural gas burners have a wide range of applications. They can be used in industrial furnaces for heating and smelting metals; in boilers to generate steam to power industrial production; in kilns for firing materials such as ceramics and cement; to provide heat energy for waste incineration; and in power plants to generate electricity. They provide reliable thermal energy for various industrial processes.

As a key component in heating and industrial systems, natural gas burners play an irreplaceable role in meeting people's heat needs with their high efficiency, safety, and environmental friendliness. Their advantages are evident in their clear and easy-to-understand operating principles, precise control, and high safety standards. Professional installation, proper model selection, and regular adjustments are crucial to ensuring optimal performance, safety, and regulatory compliance. Whether in residential or industrial applications, natural gas burners will continue to provide stable and reliable heating for our daily lives.

If you're considering installing or upgrading a natural gas burner, it's wise to consult a professional to select the right model and ensure proper installation.