In the context of continuous innovation in energy production, the search for efficient, multi-functional and environmentally friendly power generation technology is the industry continues to explore the direction. Circulating Fluidized Bed (CFB) boilers, with their unique advantages, have become the leader in this exploration of energy technology.

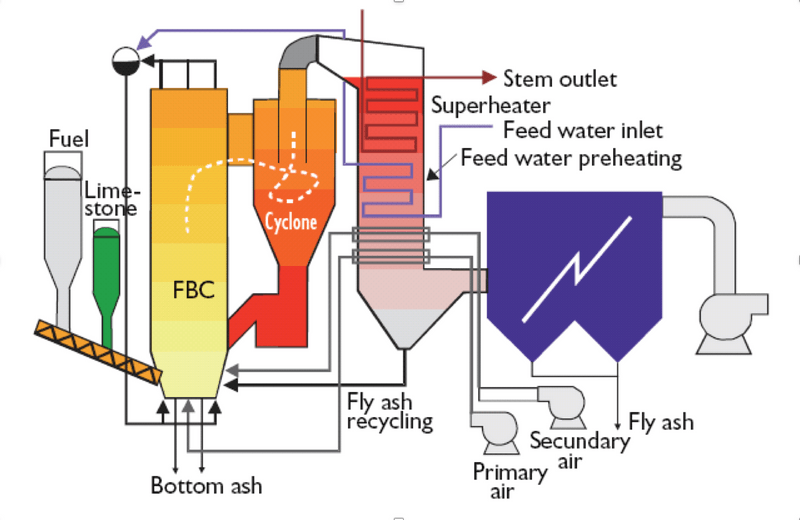

Circulating fluidized bed boiler is a kind of steam generating device that uses gas-solid fluidization technology to realize efficient combustion of fuel. During operation, the fuel and a large amount of inert bed material are held up by the high-speed gas flow in the furnace chamber, presenting a fluid-like fluidization state, so that the fuel and air are fully mixed and a violent combustion reaction occurs. At the same time, through the cyclone separator and other equipment to separate the solid particles in the high temperature flue gas, through the return device back to the bottom of the furnace chamber, to realize the cycle of combustion.

This unique design combines fluidized bed combustion technology, solid particle recovery and recycling technology, and a variety of auxiliary equipment to efficiently convert the chemical energy in the solid fuel into steam energy. Circulating fluidized bed boilers play a key role in meeting the world's growing energy demand. Their unique performance makes them the preferred choice for many industrial and power generation applications, especially under conditions that are difficult for conventional boilers to handle.

Inside the circulating fluidized bed boiler, a circulating fluidized bed of particles is maintained. This bed of pellets ensures uniform and efficient combustion of multiple fuels. The bed material is continuously circulated through a cyclone separator. This circulation process greatly improves combustion efficiency, making otherwise difficult-to-burn fuels a viable source of energy. The fluidized bed recirculation system gives the circulating fluidized bed boiler excellent fuel adaptability, enabling it to easily handle fuels of different compositions and qualities.

Based on the fluidized bed process, the circulating fluidized bed boiler achieves efficient combustion by ensuring complete fuel utilization. In large plants, circulating fluidized bed boilers are able to support supercritical steam conditions at temperatures up to 603°C and pressures up to 257 bar. This allows them to maximize energy output and demonstrate high efficiency in power generation.

Circulating fluidized bed boilers are designed for low-emission operation. Their environmental impact is minimized through advanced combustion control and optimized ash handling systems. By operating at lower combustion temperatures, the circulating fluidized bed boiler reduces the production of nitrogen oxides (NOx). At the same time, the addition of limestone enables direct desulfurization, effectively reducing sulfur dioxide (SOx) emissions. The design also ensures that carbon monoxide (CO) and total organic carbon (TOC) emissions, as well as the unburned carbon content of the ash slag, are maintained at low levels.

The circulating fluidized bed boiler is capable of burning a wide variety of fuels, covering fuels with different calorific values, types and characteristics. Moreover, it is highly resistant to fuel fluctuations and other disturbances, and remains a reliable choice when fuel quality is unstable.

By virtue of its near-complete combustion process, the circulating fluidized bed boiler produces emissions that are among the lowest in the industry. Its ability to control NOx, SOx, CO and TOC emissions makes it an environmentally friendly energy converter that can easily meet stringent environmental regulations.

The circulating fluidized bed boiler requires less excess air to operate, a feature that significantly improves its operating efficiency. In addition, it has a high burnout rate and excellent load-following capability, maintaining stable operation even under changing load conditions.

The reliable design of the circulating fluidized bed boiler ensures its high availability and long service life, reducing the need for frequent replacement and maintenance and, in the long run, lowering the cost of use and maintenance workload.

Circulating fluidized bed boilers are ideal for projects that require the use of multiple fuels, especially where the calorific value of the fuel varies greatly. It can flexibly adapt to the characteristics of different fuels to ensure a stable supply of energy.

In projects that have to use high sulfur coal, the circulating fluidized bed boiler can effectively manage sulfur emissions by adding limestone during the combustion process, solving the pollution problems caused by high sulfur coal combustion.

In areas, countries or regions with stringent emission requirements, circulating fluidized bed boilers can reduce SO2, NOx and CO emissions to extremely low levels by controlling combustion temperatures to 800 - 900°C and utilizing limestone to meet stringent environmental standards.

Although circulating fluidized bed boilers have a lower investment cost than pulverized coal (PC) boilers, they still have a higher investment cost compared to most other technologies. As a result, circulating fluidized bed boilers are more viable from an economic standpoint in high capacity applications. Especially in thermal power projects using supercritical steam parameters, it is the preferred choice for such projects due to its uniform heat distribution within the combustion chamber, especially at the location with the lowest water temperature (lower combustion chamber) where the heat flux is the highest, while other solid fuel combustion technologies are not suitable for large-capacity boilers and high-steam-parameter applications.

For application scenarios where efficiency is a priority, the design and operating characteristics of circulating fluidized bed boilers enable them to meet high standards of efficiency, making them a suitable option for projects pursuing efficient energy conversion.

Growing demand for large-scale energy generation across the globe, mainly due to increasing investments in upgrading industrial facilities in developing economies, has been a key driving force for the circulating fluidized bed boiler market. Favorable policies introduced by governments to support the production and use of clean energy are also fueling the growth of the circulating fluidized bed boiler market. The urgent need to reduce NOx and COx emissions globally has led to the increasing adoption of circulating fluidized bed boilers in numerous end-use industries. Moreover, growing oil and gas industry along with rapid urbanization, industrialization, and extensive R&D activities are also driving the growth of the circulating fluidized bed boiler market.

Higher maintenance cost of circulating fluidized bed boilers may deter some potential users. Decreasing availability of casting materials and gradual depletion of fossil fuels also pose a challenge to the market growth.

The amount of fuel required for combustion in circulating fluidized bed boilers is less as compared to the amount of high temperature materials used inside them, a feature that creates positive expectations for market growth. With continuous technological advancements and evolving industry needs, circulating fluidized bed boilers are expected to play a more significant role in the energy sector.

Circulating fluidized bed boilers occupy an important position in the field of energy production due to their unique working principle, significant advantages, wide range of application scenarios, and market prospects full of opportunities and challenges. As the global demand for efficient and clean energy continues to grow, circulating fluidized bed boilers, by virtue of their own characteristics, have the potential to become one of the key technologies to meet future energy needs. Whether you are in the energy industry or concerned about energy development, it is worthwhile to further explore circulating fluidized bed boilers in depth and consider applying this technology in appropriate projects.