Rubber manufacturing is a systematic process that requires extremely stringent temperature and humidity control. From the pretreatment of rubber raw materials to the molding of the final product, every step depends on a continuous and stable supply of heat and steam. The production of tires, rubber hoses, and rubber seals requires a specific temperature environment to fuse the raw materials, optimize the molecular structure, and solidify the product's performance. Boilers are the core equipment that provides these critical energy sources.

In rubber processing plants, boilers play an irreplaceable role. They are not only a source of heat and steam but also directly impact the continuity of the production process. A boiler failure or unstable steam supply can bring the entire production line to a standstill, resulting in significant economic losses. Furthermore, selecting the right boiler can fundamentally improve production efficiency: stable steam output reduces waiting time in the production process and increases productivity per unit time; precise temperature control ensures consistent quality across batches and reduces defective product rates; and boilers that meet environmental standards can reduce pollutant emissions, helping companies meet increasingly stringent environmental regulations and enhance their green competitiveness.

Heat is a catalyst in many key steps of rubber processing. During the rubber mixing process, heat is required to fully blend the rubber raw materials with various additives (such as vulcanizers and fillers). Insufficient or uneven temperature distribution will result in incomplete mixing of the raw materials, directly affecting the strength and elasticity of the subsequent product. During the vulcanization process, heat is crucial for cross-linking rubber molecules. Only at a specific temperature can rubber molecules form a stable three-dimensional network structure, imparting excellent elasticity, wear resistance, and aging resistance to the product. During the drying process, heat is used to remove excess moisture from the semi-finished rubber product, preventing residual moisture from causing defects such as bubbles and cracks.

There are significant differences between direct heating and steam heating. Direct heating typically involves direct contact with the material through electric heating tubes or flames. While this method heats up quickly, it can easily lead to localized overheating, causing the rubber raw material to burn or deteriorate in performance, and making temperature uniformity difficult to control. Steam heating, on the other hand, releases heat through the steam's phase change, resulting in gentler and more uniform heat transfer. This ensures consistent temperature across the material, and offers a wide temperature adjustment range, allowing for precise control based on the needs of different processing steps. From a long-term production perspective, steam heating offers advantages in terms of efficiency and product quality.

A stable steam supply is a "double guarantee" for rubber production efficiency and quality. During the vulcanization process, steam heats the vulcanizer or autoclave, providing a constant temperature environment for the rubber. Fluctuations in steam pressure or temperature can lead to under- or over-vulcanization. The former results in poor product elasticity and deformation, while the latter results in hardness and increased brittleness. Only a continuous and stable steam supply can ensure consistent vulcanization results for each batch, avoid rework and waste caused by quality issues, and indirectly improve production efficiency.

Steam quality is closely linked to the performance of the final rubber product. High-quality steam (low water content, high purity) enables more uniform heat transfer, ensuring sufficient and even cross-linking of rubber molecules. This in turn improves product elasticity – enabling rubber products to quickly return to their original shape after being subjected to stress. It also enhances durability – extending the product's resistance to aging and wear during use. It also improves appearance – reducing surface defects (such as spots and inconsistent textures) caused by uneven temperatures, thereby enhancing the product's market competitiveness.

As an efficient and flexible energy carrier, steam plays an irreplaceable role in multiple production processes in rubber plants. Specific application scenarios are shown in the table below:

|

Process Step |

Steam Usage Method |

Application Purpose / Advantages |

|

Rubber Mixing |

Preheating rubber mixture |

Reduces viscosity of raw rubber, promotes uniform mixing with additives, enhances mixture consistency, and lays a solid foundation for subsequent processing. |

|

Vulcanization |

Heating vulcanization presses and autoclaves |

Provides stable temperature conditions for rubber molecular cross-linking, ensures thorough and uniform vulcanization, and imparts desired physical properties (e.g., elasticity, strength). |

|

Drying Treatment |

Heating dry air or drying chambers |

Rapidly removes moisture from rubber semi-finished products, prevents defects like bubbles, delamination, or cracking in subsequent processing, and ensures structural stability of the product. |

|

Mold Heating |

Direct or indirect steam injection |

Maintains consistent mold temperature, prevents dimensional deviations or surface irregularities in finished rubber products, and improves molding precision. |

|

Plant Utilities |

Providing steam or hot water |

Used for cleaning workshop equipment (high-temperature steam efficiently removes oil stains), preheating raw materials (reduces subsequent heating energy consumption), and space heating in workshops during winter, improving the production environment. |

Steam heating has become the preferred heating method for rubber production due to its unique advantages: First, steam offers high heat transfer efficiency. Steam releases a large amount of latent heat during its phase change, rapidly transferring heat to the material. Furthermore, it offers precise temperature control, allowing the temperature to be adjusted to a specific range (typically between 100-200°C) based on the requirements of different processing steps, meeting the diverse needs of rubber processing. Second, steam heating is highly compatible, allowing the system to flexibly adapt to both intermittent production (such as small-batch custom rubber products) and continuous production (such as large-scale tire manufacturing), eliminating the need for major equipment adjustments. Finally, steam heating enables efficient energy utilization. Waste steam generated during production can be reused through waste heat recovery systems (such as preheating cold water and heating workshops), reducing energy waste and lowering energy costs for the company.

Different boiler types vary in fuel, efficiency, and environmental performance. Rubber companies need to select the appropriate boiler type based on their production needs, regional resource conditions, and environmental requirements. The details are as follows:

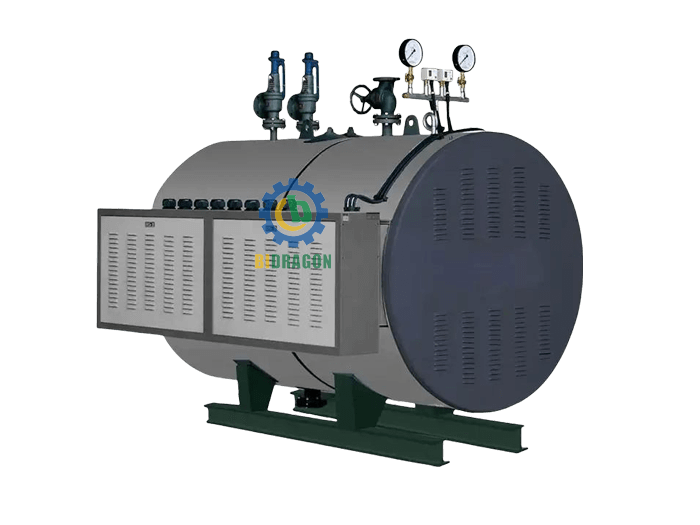

Common models include the WNS series (horizontal internal combustion oil-fired gas boilers) and the SZS series (double-drum vertical oil-fired gas boilers). The core advantage of these boilers lies in their high combustion efficiency—they utilize advanced burners to ensure complete fuel combustion, typically achieving thermal efficiencies exceeding 90%. They also offer low emissions, with minimal nitrogen oxide (NOx) emissions during combustion, meeting current mainstream environmental standards. Furthermore, gas-fired boilers offer a high degree of automation, enabling one-touch start and stop, and automatic steam pressure and temperature adjustment, reducing manual operation costs. Because they rely on natural gas, gas-fired steam boilers are particularly suitable for modern rubber plants located in industrial areas with well-established natural gas pipeline networks.

Mainstream models include the DZL series (single-drum vertical biomass boiler), the SZL series (double-drum vertical biomass boiler), and the DZH series (single-drum horizontal biomass boiler). These boilers use biomass fuels (such as rice husks, wood chips, palm shells, and straw) as a renewable energy source, offering significant environmental advantages. Carbon dioxide emitted during combustion is absorbed by plant photosynthesis, completing the carbon cycle and reducing the company's carbon footprint. Furthermore, biomass fuel is generally cheaper than natural gas and coal, helping companies control their long-term fuel costs. However, biomass boilers require higher fuel stability and are more suitable for rubber plants located in areas rich in agricultural and forestry resources (such as rice-producing areas and areas with concentrated timber processing).

Coal-fired steam boilers are a traditional type of boiler. Their greatest advantage lies in their economic efficiency. Coal fuel is relatively inexpensive and its supply is stable, reducing initial fuel costs for enterprises. Furthermore, coal-fired boilers offer high steam output capacity, providing continuous, stable, high-pressure steam to meet the needs of large-scale rubber production (such as tire manufacturing). However, these boilers also have significant drawbacks: the combustion process generates significant amounts of pollutants such as dust and sulfur dioxide, requiring comprehensive dust removal and desulfurization equipment to comply with local environmental regulations. Furthermore, routine maintenance is arduous, requiring regular furnace cleaning and replacement of components such as grates, increasing operational costs. Currently, coal-fired steam boilers are still used in rubber plants in coal-rich regions (such as some northern industrial areas).

Electric steam boilers are characterized by their compact structure, small footprint, and the absence of fuel storage space, making them easy to install and commission. Furthermore, they emit no waste gas or waste residue during operation, achieving "zero pollution at the point of use" and meeting stringent environmental requirements (such as small rubber plants near urban areas). Electric steam boilers are also simple to operate, with intelligent control systems allowing for precise adjustment of steam parameters and low maintenance costs. However, due to their reliance on electricity, their operating costs are significantly affected by electricity prices, and their steam production capacity is relatively limited. They are therefore more suitable for small-scale production and testing needs in small rubber workshops (such as rubber seal manufacturers) or rubber product R&D institutions.

|

Rubber Plant Type |

Recommended Boiler Type |

Typical Capacity |

Fuel Type |

Core Advantages |

|

Tire Factory |

WNS Gas Steam Boiler |

6-10 tons |

Natural Gas |

Clean and pollution-free, meeting environmental requirements for mass production; high automation enables precise control of steam pressure and temperature, satisfying the strict demands of key processes like tire vulcanization. |

|

Hose Factory |

DZL Biomass Steam Boiler |

4-8 tons |

Biomass Fuel |

Low energy cost, suitable for the medium-scale steam demand of hose production; stable steam output ensures uniformity in the hose vulcanization process, guaranteeing stable product performance. |

|

Rubber Shoe Factory |

DZL Coal-Fired Steam Boiler |

2-6 tons |

Coal |

Low initial investment cost, meeting the small-scale steam demand for rubber shoe production; fuel supply is easily accessible, suitable for small and medium-sized shoe factories sensitive to cost control. |

|

Conveyor Belt Factory |

WNS Gas Steam Boiler |

6-10 tons |

Natural Gas |

Stable steam pressure with minimal temperature fluctuation, ensuring dimensional accuracy and surface quality during conveyor belt vulcanization; high operational reliability reduces production line downtime caused by boiler failures. |

Rubber plants vary in production scale, product requirements, and energy requirements. Therefore, the corresponding boiler configurations must be tailored to the specific conditions. Specific recommendations are as follows:

When selecting a steam boiler, rubber companies must comprehensively evaluate multiple factors to ensure a sound and rational selection:

Different processing stages have different steam requirements. For example, the vulcanization stage typically requires higher steam pressure (0.8-1.2 MPa), while the drying stage requires a relatively lower pressure (0.4-0.6 MPa). Companies should determine the rated capacity of the boiler based on the total steam consumption of the production line (calculated based on the number of equipment and production cycle) to avoid production constraints due to insufficient capacity or energy waste due to excessive capacity.

Local fuel availability directly impacts boiler operating costs and stability. If local natural gas supply is sufficient and reasonably priced, gas-fired boilers are preferred. If biomass resources are abundant, biomass boilers are a better choice. Furthermore, local environmental policies must be strictly adhered to. For example, in areas with stringent environmental requirements, coal-fired boilers without efficient dust removal and desulfurization equipment should be avoided to avoid penalties for substandard emissions.

A boiler's thermal efficiency directly determines energy utilization. High-efficiency boilers can significantly reduce long-term operating costs. Highly automated boilers reduce manual operations and the risk of failures caused by human error. Boilers with low maintenance requirements (such as gas-fired boilers) can reduce downtime and improve equipment utilization.

Boiler failures are inevitable during long-term operation. A comprehensive local after-sales service network ensures rapid response and repair, minimizing production line downtime. Furthermore, readily available spare parts reduce maintenance costs and ensure long-term stable operation.

Steam boilers are the indispensable energy heart of the rubber production process. Their stable operation is the foundation for continuous production and high-quality products. Selecting the right steam boiler type not only improves energy efficiency and reduces production and environmental costs, but also enables precise temperature and steam control to consistently deliver high-quality rubber products, giving companies a competitive advantage in the market.

Therefore, rubber companies need to combine their actual needs, scientifically select and reasonably configure boilers, so that boilers become the core driving force for production development.