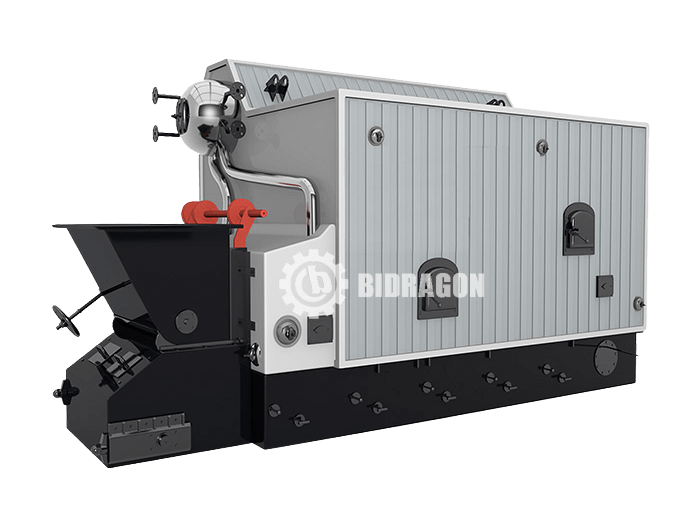

A solid fuel steam boiler is a thermal energy device that uses solid fuels (such as coal, wood, biomass, etc.) as its energy source. By burning these fuels to generate heat, it heats water to boiling and produces steam. Its core function is to convert the chemical energy of solid fuels into the thermal energy of steam, providing power for subsequent industrial production or energy supply.

During operation, pretreated solid fuel is fed into the boiler combustion chamber, where it undergoes complete combustion to release heat. This heat transfers to the boiler's heat transfer surfaces, causing the water within them to absorb heat and gradually increase in temperature, ultimately transforming into saturated steam or superheated steam.

Within the contemporary industrial energy landscape, solid fuel steam boilers hold significant importance: From a cost-efficiency perspective, solid fuels generally cost less than natural gas, oil, and other fuels, effectively reducing corporate operating expenses. Regarding energy security, they can leverage locally abundant solid fuel resources, reducing dependence on imported energy. In terms of sustainability, the use of fuels like biomass and solid waste enables resource recycling, aligning with green development trends. Currently, they are widely deployed across critical industrial sectors including power generation, textiles, chemicals, and food processing.

First, solid fuel is conveyed into the boiler's fuel hopper via feeding equipment, then uniformly delivered into the combustion chamber by the feeder. Subsequently, the fuel is ignited by the ignition device. Within the combustion chamber, the fuel mixes with an appropriate amount of air, undergoing complete combustion reactions that release substantial heat. The resulting high-temperature flue gas then flows through the boiler's heat transfer surfaces (such as water walls and convection tubes), transferring heat to the water within these surfaces via conduction and convection. As the water absorbs heat, its temperature gradually rises. Upon reaching the boiling point, it transforms into saturated steam. If steam with higher parameters is required, the saturated steam continues through a superheater, absorbing additional heat to become superheated steam. Finally, the generated steam is transported via steam pipes to the user end. After completing heat transfer, the high-temperature flue gas enters purification equipment like dust collectors and desulfurization systems through the flue system. Once treated to meet standards, it is discharged through the stack. The ash and slag produced by combustion are removed from the boiler via ash removal devices.

Furnace and Combustion Chamber: The core area for solid fuel combustion, providing ample space for fuel burning while ensuring efficient heat transfer to the heat transfer surfaces.

Drum (Water Drum): Stores boiler water and separates steam from water to ensure steam quality. It also regulates boiler water quality and maintains normal water level.

Heat Transfer Surfaces: Including water walls, convection tubes, and superheaters, these are critical components for heat transfer. They are responsible for transferring the heat released from fuel combustion to the water inside the boiler, converting it into steam.

Flue System: Comprising flue ducts, dust collectors, desulfurization equipment, induced draft fans, and chimneys, it guides high-temperature flue gas flow, purifies emissions to reduce pollutant discharge, and ultimately discharges compliant flue gas into the atmosphere.

Fuel Supply: Precisely controls fuel feed rates via feeding devices according to boiler load demands, ensuring stable and uniform fuel entry into the combustion chamber. This prevents combustion instability and reduced thermal efficiency caused by excessive or insufficient fuel supply.

Air Control: The blower delivers appropriate air volumes (including primary and secondary air) into the combustion chamber. Primary air primarily carries fuel into the chamber and provides initial combustion air, while secondary air supplements combustion air to promote complete fuel combustion. Simultaneously, the induced draft fan regulates flue gas flow velocity by adjusting flue gas pressure, ensuring stable combustion processes.

Ash Removal: Ash and slag generated during combustion can accumulate on heat transfer surfaces or within the combustion chamber, impairing heat transfer efficiency and potentially creating safety hazards. Ash removal systems must periodically clear deposits from heat transfer surfaces and combustion chambers to ensure efficient and safe boiler operation.

Fuel Supply and Ignition: Solid fuel is delivered to the combustion chamber via the feeding system. The ignition device activates, igniting the fuel and initiating the combustion process.

Heat Transfer to Water: High-temperature flue gas released from fuel combustion contacts the heat transfer surfaces. Through heat transfer, thermal energy is transferred to the water within these surfaces, gradually raising its temperature.

Steam Generation and Collection: Water absorbs heat until it reaches boiling point and converts to steam. Steam undergoes steam-water separation within the drum, where separated steam is collected and piped to the user end.

Flue Gas Discharge and Ash Removal: Low-temperature flue gas, having completed heat transfer, is discharged after purification through the flue system. Combustion ash is removed from the boiler via ash removal devices to maintain internal cleanliness.

The fixed grate boiler features a stationary grate in the furnace. Solid fuel is manually or mechanically placed on the fixed grate for combustion, and the ash generated after combustion is manually cleaned regularly. It has a simple structure, low manufacturing cost, and is suitable for small-scale steam demand scenarios with low fuel consumption.

This type employs a moving chain grate to transport solid fuel. Fuel is evenly spread on the chain grate at the front end. As the chain moves slowly, the fuel sequentially undergoes drying, ignition, combustion, and burnout processes. Ash is automatically discharged at the tail end of the grate. It enables continuous fuel feeding and ash discharge, featuring stable combustion and high thermal efficiency, making it suitable for medium to large-scale industrial steam production.

The reciprocating grate boiler employs a grate composed of multiple reciprocating fire bars. Through the alternating movement of these fire bars, fuel is continuously turned and pushed forward, promoting complete combustion and uniform heat release. It demonstrates excellent adaptability to diverse solid fuels, particularly those with high moisture content or poor combustibility, and is widely employed in industrial settings with variable fuel quality.

In a fluidized bed boiler, the furnace is filled with a specific quantity of inert particles (such as quartz sand). When high-speed air is blown into the furnace from the bottom, the inert particles and solid fuel are in a fluidized state, similar to a boiling liquid. The fuel burns fully in the fluidized layer, and the heat transfer efficiency is extremely high. It can burn a variety of low-calorific-value solid fuels (such as coal gangue, biomass waste) and has strong environmental protection performance, which is widely used in large-scale industrial projects.

Utilizing coal (such as anthracite, bituminous coal, lignite, etc.) as the primary fuel, it features high thermal efficiency and stable output, capable of meeting the substantial steam demands of large-scale industrial production. Consequently, it is extensively applied in heavy industries like power generation, metallurgy, and chemical manufacturing. However, its combustion process may generate significant pollutants such as dust and sulfur dioxide, necessitating comprehensive environmental treatment equipment.

Utilizing biomass fuels (such as straw, wood chips, rice husks, palm shells, etc.), these fuels are renewable energy sources. Their carbon dioxide emissions after combustion are significantly lower than fossil fuels, effectively reducing greenhouse gas emissions and meeting environmental requirements. They are suitable for regions rich in biomass resources, such as small and medium-sized industrial enterprises in agricultural and forestry production areas, as well as projects with stringent environmental requirements.

Utilizing municipal solid waste or industrial solid waste (e.g., waste paper, plastics, rubber, industrial residues) as fuel, these boilers achieve waste reduction and harmless treatment while converting waste energy into steam, enabling resource recycling. Commonly deployed in municipal waste treatment plants and industrial waste processing centers, they address waste disposal challenges while providing clean energy.

Capable of flexibly switching or blending multiple solid fuels (e.g., coal and biomass, biomass and solid waste). It adjusts fuel ratios or switches fuel types based on market prices, supply conditions, and boiler load requirements, thereby optimizing operating costs and enhancing operational stability and flexibility. Suitable for industrial enterprises with unstable fuel supply or pursuing cost optimization.

Procurement costs for solid fuels (such as coal, biomass, and solid waste) are generally lower than those for fuels like natural gas and petroleum. Certain solid wastes can be obtained at low cost or even free of charge. Additionally, boilers exhibit high fuel consumption efficiency during operation, effectively controlling energy expenditures and significantly reducing long-term operational costs for enterprises.

Compatible with diverse solid fuels including coal, wood, straw, rice husks, palm shells, and solid waste. Businesses can flexibly select or switch fuel types based on market availability, price fluctuations, and production needs, mitigating operational risks from single-fuel shortages or price spikes.

In off-grid or rural areas where natural gas pipelines and electricity supply may be unstable or unavailable, solid fuel steam boilers operate independently of stable gas pipelines or high-capacity power grids. They reliably generate steam using locally accessible solid fuels to meet demands for agricultural processing, small-scale industrial production, and residential heating, ensuring high operational reliability.

When using renewable fuels like biomass, the carbon dioxide absorbed during fuel growth largely balances that released during combustion, achieving near-zero or low carbon emissions. This approach reduces reliance on fossil fuels, lowers overall carbon emissions, and helps businesses minimize their carbon footprint—aligning with environmental policies and green development requirements.

The boiler body is typically constructed from high-quality steel with a robust structural design capable of withstanding harsh operating conditions like high temperatures and pressures. Furthermore, solid fuel combustion causes relatively low corrosion to internal components. With proper routine maintenance, the boiler's service life can typically reach 15-20 years or longer, providing enterprises with long-term, stable energy support.

In power generation, high-temperature, high-pressure steam from solid fuel steam boilers drives turbine rotation, which in turn powers generators to supply electricity to the grid. In cogeneration systems, steam first generates electricity, while the resulting low-temperature steam or hot water is utilized for industrial heating, residential heating, and other applications. This achieves cascading energy utilization, enhancing overall energy efficiency. Such systems are widely deployed in thermal power plants and industrial park heat centers.

Textile Industry: Steam is used in processes like dyeing, setting, and drying textile fibers, requiring stable low-to-medium pressure steam to ensure uniform fabric quality.

Food Industry: Steam is employed in cooking, sterilization, and drying during food processing—such as canning, dairy production, and grain processing—demanding high-purity steam with controllable temperatures.

Paper Industry: Massive steam volumes are required for pulp cooking and paper drying. Boilers must deliver continuous, stable steam supply to maintain uninterrupted paper production.

Chemical Industry: Steam powers heating for chemical reactions, preheating raw materials, and separating/purifying products. Certain chemical processes impose strict pressure and temperature requirements on steam. In fertilizer manufacturing (e.g., nitrogen and phosphate fertilizers), steam facilitates raw material decomposition and synthesis reactions. Solid-fuel steam boilers deliver sufficient thermal energy to meet large-scale fertilizer production demands.

Wood Drying: Steam heats air, which removes moisture from wood while controlling drying speed and intensity. This prevents warping and cracking, ensuring wood processing quality.

Palm Oil Processing: Steam is used for palm fruit steaming, crude oil refining after pressing, and other processes. A stable steam supply is essential to enhance palm oil extraction rates and quality.

Sugar Production: Extensive steam is required for juice extraction, evaporation, and crystallization of sugarcane or sugar beets. Boiler-generated steam provides thermal energy for sugar extraction and purification.

During municipal waste treatment, garbage is fed into solid fuel steam boilers for combustion. The generated steam can be utilized for power generation or heating, achieving waste reduction and energy recovery. Such projects address urban waste accumulation while providing clean energy to cities, aligning with environmental protection and resource recycling principles. They are commonly found in waste-to-energy plants within large and medium-sized cities.

Select a site with level terrain, good ventilation, and distance from flammable or explosive materials. Ensure sufficient operational space and maintenance access for future equipment servicing and personnel operations. The boiler foundation must be designed based on the boiler model, weight, and local geological conditions. Constructed using poured concrete, it must ensure sufficient strength to withstand the boiler's operational weight and vibrations, preventing displacement or tilting during operation.

Fuel storage areas must be rainproof, moisture-proof, and fireproof. Different types of solid fuels should be stored separately to avoid cross-contamination or chemical reactions. Storage capacity should be rationally planned based on boiler fuel consumption and supply cycles to ensure stable fuel availability. The fuel processing system must include crushing, screening, and conveying equipment to prepare solid fuels to the particle size and form required for boiler combustion. This includes breaking large coal chunks into smaller pieces and removing impurities from biomass fuels to ensure uniform and stable fuel feeding into the combustion chamber.

Local installation teams possess deep familiarity with regional climate conditions, geological features, regulatory frameworks, and industrial environments. This enables them to optimize installation plans based on actual conditions and enhance installation efficiency. Furthermore, local teams facilitate smoother communication during the installation process, allowing for prompt resolution of any issues that arise. Additionally, professional installation teams bring extensive experience and specialized technical expertise. They strictly adhere to boiler installation specifications and safety standards, ensuring high-quality installation and preventing safety hazards or operational inefficiencies caused by improper installation.

Cleaning Heat Transfer Surfaces: Regularly remove ash and slag deposits from heat transfer surfaces (e.g., water walls, convection tubes, superheaters). Accumulated ash and slag impede heat transfer, reduce boiler thermal efficiency, and may cause overheating damage to heat transfer surfaces in severe cases.

Ash Removal: Promptly clear ash and slag from the combustion chamber and flue passages to prevent accumulation that could impair combustion conditions and flue gas flow. This also prevents flue blockages that could trigger safety incidents.

Airflow and Water Level Inspection: Regularly inspect the operational status of forced draft fans and induced draft fans to ensure unobstructed air supply and flue gas exhaust, maintaining proper negative pressure in the combustion chamber. Simultaneously, closely monitor drum water levels to keep them within normal ranges, preventing steam carryover due to excessively high water levels or dry firing accidents caused by excessively low water levels.

Conduct periodic non-destructive testing on the boiler body and pressure-bearing components (e.g., drums, water walls, convection tubes) to detect cracks, corrosion, deformation, or other defects, ensuring their safety and reliability. Calibrate safety accessories like safety valves, pressure gauges, and water level indicators to ensure their responsiveness and accuracy, enabling timely activation during abnormal boiler operation to safeguard safety. Simultaneously, inspect auxiliary equipment such as fuel supply systems, dust removal and desulfurization units, and control systems. Promptly replace aged or damaged components to ensure stable operation of the entire boiler system.

Gas-fired boilers utilize fuels like natural gas or liquefied petroleum gas (LPG). They produce fewer pollutants (e.g., dust, sulfur dioxide) during combustion, offer high combustion efficiency, and feature high automation for convenient operation and rapid startup. However, gas prices typically exceed those of solid fuels, and reliable pipeline supply is essential. In regions with limited gas availability or high gas costs, operational expenses can be significant.

Oil-fired boilers utilize liquid fuels like diesel or heavy oil. Fuel transportation and storage are relatively convenient, combustion is stable, and output adjustment is flexible, making them suitable for areas without gas supply or with unstable gas supply. However, oil prices are significantly influenced by international oil prices, fluctuate frequently, and result in higher long-term operating costs. Additionally, oil combustion produces nitrogen oxides and particulate matter, creating significant environmental emission pressures. Comprehensive oil storage and fire prevention facilities are also required.

Electric boilers utilize electricity as their energy source, heating water into steam via electric heating elements. They offer advantages such as simple structure, compact size, easy installation, high automation, and zero pollutant emissions. They are suitable for areas with stringent environmental requirements, ample power supply, and low electricity rates, or for small-scale steam demand scenarios. However, electric boilers consume substantial electricity during operation. In industrial high-load steam demand scenarios, electricity costs become prohibitively high, resulting in significantly higher operating expenses compared to solid fuel boilers. Additionally, they are highly dependent on stable power supply and cannot operate during power outages.

Solid fuel boilers use a variety of solid fuels as their energy source. They offer low fuel costs and a wide range of fuel sources, unconstrained by gas or electricity supply, resulting in significant operating cost advantages. They also offer high fuel flexibility, allowing for the selection of fuels based on practical needs, making them suitable for a wide range of industrial scenarios. However, the combustion process may produce certain pollutants, requiring environmental treatment equipment. Furthermore, their level of automation is lower than that of gas and electric boilers, leading to a higher level of daily maintenance.

Comparison Summary Table

|

Boiler Type |

Advantages |

Disadvantages |

|

Solid Fuel Boiler |

Low fuel cost, fuel flexibility, stable supply |

Requires environmental treatment, low automation, high maintenance |

|

Gas Boiler |

Clean and eco-friendly, high combustion efficiency, high automation |

High fuel cost, reliance on gas pipelines |

|

Oil Boiler |

Convenient fuel transport, flexible output adjustment |

Cost influenced by oil prices, emission pressure |

|

Electric Boiler |

Zero pollutant emissions, easy installation, high automation |

High cost under heavy load, reliance on power supply |

Solid fuel steam boilers hold a significant position in the industrial energy sector of developing countries due to their low cost and stable fuel supply. Simultaneously, biomass and solid waste energy boilers continue to expand their market applications as they align with renewable energy trends. Technologically, their deep integration with “solid fuel + gas/electricity” hybrid systems and intelligent control systems enables dynamic energy allocation and automated parameter optimization, significantly enhancing operational efficiency and reducing manual risks.

Against the backdrop of a global energy transition toward sustainability and decentralization, solid fuel steam boilers leverage renewable fuels and local resources to meet environmental standards while reducing dependence on centralized energy sources. Looking ahead, technological advancements in efficient combustion and emissions control will further solidify their role as green, reliable core components of industrial energy systems, becoming essential elements in new industrial frameworks.