In industrial production systems, boilers, as core thermal energy conversion equipment, are widely used in key sectors such as power generation, chemical engineering, metallurgy, and textiles. They fulfill the crucial role of providing steam power or hot water for production processes. Their stable operation directly determines the efficiency and continuity of industrial production lines. However, when operating under high-temperature and high-pressure conditions, boilers are prone to safety incidents due to problems such as abnormal water levels and uncontrolled pressure. These can lead to equipment downtime at the very least, or even catastrophic consequences such as explosions and casualties. Therefore, comprehensive safety protection devices are an indispensable component of industrial boilers, and fusible plugs, as key components for preventing boiler overheating, play an irreplaceable role in this safety protection system.

A fusible plug is a passive safety device designed based on the principle of thermal sensing. Its core function is to release pressure and provide an alarm by melting its own melt when the internal temperature of the boiler exceeds a safety threshold, thereby preventing equipment damage or explosion due to overheating. Compared to the safety valve, another key safety device in boilers, the two have fundamentally different protection logics: A safety valve operates by sensing pressure changes. When the pressure inside the boiler exceeds the set value, the valve automatically opens to release pressure, and closes when the pressure returns, primarily addressing overpressure risks. Fusible plugs, on the other hand, operate by sensing temperature changes and only trigger when the equipment overheats (usually caused by low water levels), specifically addressing overheating risks. The two form a complementary safety protection system.

In the industrial sector, fusible plugs have a wide range of applications. In addition to core industrial steam boilers, they are also commonly used in compressed air storage tanks, hot oil heating systems, and low-pressure liquefied gas storage equipment. They play a critical safety role, particularly in temperature-sensitive industrial environments where open flames must be avoided.

The structural design of an industrial-grade fusible plug must balance high-temperature resistance, corrosion resistance, and precise triggering. Its core components are the outer shell material and the melt:

Outer shell material: Primarily made of brass, bronze, or gunmetal (a copper-zinc alloy). These metals offer excellent high-temperature resistance (capable of withstanding prolonged operating temperatures exceeding 200°C), resistance to water vapor corrosion, and high thermal conductivity, quickly transferring the internal boiler temperature to the melt, ensuring timely triggering.

Melt: As the core sensing element of the fusible plug, a low-melting-point metal with a stable melting point and good fluidity after melting is required. Common types include tin (melting point approximately 232°C, suitable for medium- and low-temperature industrial boilers), lead (melting point approximately 327°C), bismuth (melting point approximately 271°C), and cadmium (melting point approximately 321°C). In practice, alloys of two or more metals are often used to precisely match the safety temperature thresholds of different boilers. The melting point of the melt directly determines the safety protection mechanism of the fusible plug. When designing an industrial boiler, a melt with a melting point 50-100°C below the dangerous overheating temperature of the furnace is selected based on parameters such as the furnace material (for example, the safe temperature tolerance for carbon steel furnaces is approximately 400°C) and operating pressure. This ensures that the melt melts before the furnace reaches its critical overheating temperature, triggering protective action.

In the industrial boiler safety protection system, the fusible plug is the last active line of defense against the risk of furnace overheating due to low water levels. Its functions cover multiple dimensions, including risk monitoring, emergency response, and safety warnings. These functions can be categorized into the following six key aspects:

When the water level in an industrial boiler continues to drop due to feedwater pump failure, water level gauge malfunction, or operator error, the heating surfaces of the furnace (especially the furnace roof in fire-tube boilers) lose their water cooling protection and are directly exposed to the high-temperature furnace flames, causing the temperature to rapidly rise to over 400°C. At this point, if the safety valve fails to trigger due to pressure not exceeding the specified limit, the molten material in the fusible plug will rapidly melt upon reaching the set melting point, forming a pressure relief channel. High-temperature steam is ejected at high speed through the fusible plug hole, reducing internal boiler pressure and preventing explosion due to overheating. Furthermore, it dissipates a large amount of heat, slowing the rise in furnace temperature and buying valuable time for operators to respond to emergency situations. This serves as the "last barrier" to prevent explosions.

Low water level is one of the most common safety hazards in industrial boilers, and fusible plugs serve as a precise sensor for monitoring this risk. It is typically installed 5-10mm below the water level at the boiler's top (near the "minimum safe water level").

When the water level is normal, the fusible plug shell is continuously cooled by water, maintaining the melt temperature at 100-150°C (below its melting point), keeping it solid.

When the water level drops below the minimum safe level, the fusible plug shell loses its cooling effect and comes into direct contact with the high-temperature flue gas in the furnace, which reaches 800-1200°C. This heat is quickly transferred to the melt, causing it to reach its melting point and melt within 3-5 minutes.

Once the melt melts, high-pressure steam from the boiler immediately ejects through the fusible plug's center hole. The sound of the steam flowing creates a clear alarm, while the ejected steam directly impacts the furnace flame, suppressing combustion intensity and preventing further overheating. This creates a closed-loop protection system of "monitoring - response - cooling."

In the noisy environment of industrial workshops, traditional electronic alarms (such as buzzers) can be masked. However, the "high-speed steam jet" sound (volumes reaching 80-100 decibels) produced when a fusible plug is triggered is highly penetrating and quickly draws the operator's attention. Furthermore, the visual "white mist" phenomenon accompanying the steam jet helps operators quickly locate the fault (i.e., the fusible plug installation point), shortening fault diagnosis time. This intuitive combination of sound and light effectively reduces the risk of further equipment damage caused by unnoticed alarms and the risk of personnel accidentally entering hazardous areas.

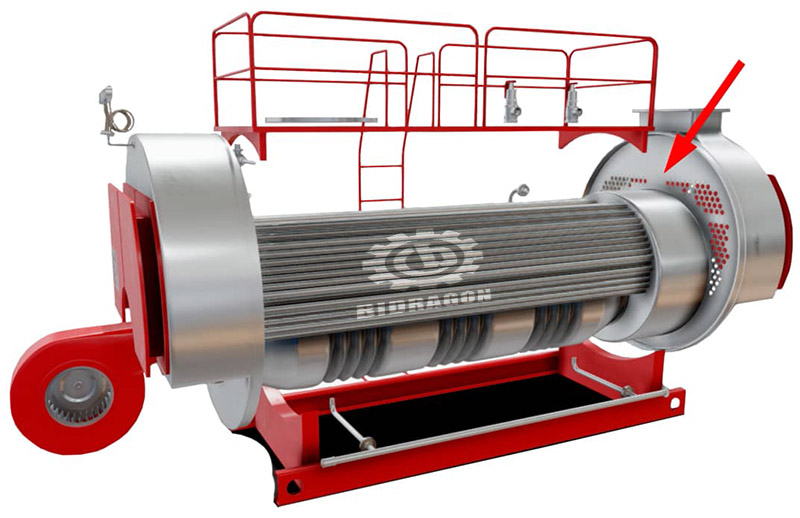

Fire-tube boilers are one of the most widely used boiler types in industrial sectors (such as textiles and food processing). Their crown sheet is the critical heating surface in direct contact with the flames and is relatively thin (typically 10-15mm). Without water cooling, it is prone to deformation due to overheating (carbon steel will undergo significant plastic deformation at temperatures exceeding 350°C), leading to bulging and cracking of the crown sheet. Therefore, the fusible plug in a fire-tube boiler must be precisely installed in the center of the crown sheet—this location is where the crown temperature is highest and most susceptible to overheating. This prioritizes temperature anomalies and triggers protection, preventing structural damage caused by crown deformation due to overheating and extending the boiler's service life.

The role of fusible plugs varies significantly across different industrial boilers, requiring their application to be tailored to the boiler's specific characteristics:

Fire-tube boilers: As a core safety device, they are the primary means of preventing crown overheating. Because fire-tube boilers operate at relatively low pressures (typically ≤1.6 MPa), the risk of overheating is much greater than the risk of overpressure. Therefore, the reliability of the fusible plug directly determines boiler safety.

High-pressure boilers (such as power plant boilers, with pressures ≥9.8 MPa): Serves as a secondary protection device. High-pressure boilers have a higher risk of overpressure, and safety valves are the primary protection. Fusible plugs are only activated when low water levels cause localized overheating (such as a dry burn in a water-wall tube), compensating for the safety valve's inadequate response to overheating risks.

Marine boilers: Serves as an emergency protection device. Marine boilers are confined, subject to significant vibration, and experience frequent water level fluctuations. Fusible plugs must be vibration-resistant and corrosion-resistant, ensuring rapid activation in the event of a water level control system failure to prevent accidents from escalating and impacting ship safety.

Based on the triggering heat source, fusible plugs for industrial boilers can be divided into two categories, each with its own specific application scenarios:

Flame-actuated: The fusible plug is installed directly inside the furnace or close to the furnace wall. It receives heat from contact with the flame or the high-temperature furnace wall. The triggering temperature is solely dependent on the flame temperature and is unaffected by the steam temperature. Suitable for boilers with direct flame contact, such as fire-tube boilers and pulverized coal-fired boilers, it can quickly detect furnace overheating risks.

Steam-actuated: The fusible plug is installed in the steam space and triggers based on changes in steam temperature. When the water level is too low, the steam temperature overheats due to furnace overheating, exceeding the saturation temperature (for example, the saturated steam temperature at 1.0 MPa is 184°C, and can reach over 250°C after overheating), thereby melting the melt. Suitable for boilers without direct flame contact, such as water-tube boilers and oil-gas boilers, it avoids false triggering caused by flame fluctuations and improves protection reliability.

The working principle of fusible plugs in industrial boilers is based on the physical process of "heat conduction - temperature triggering - pressure relief protection." Its core logic is directly linked to the boiler water level:

Installation Location: The standard installation location is below the "minimum safe water level" on the boiler roof. When the water level is normal, the fusible plug shell is completely submerged in water, with only a small amount of the top exposed to the steam space.

Normal operating conditions: The water maintains the fusible plug shell temperature at saturation temperature (varies with pressure, typically 100-200°C) through heat conduction. The melt temperature is below its melting point, remaining solid, and the fusible plug is in a "sealed state," preventing steam leakage.

Abnormal operating conditions: When the water level drops below the minimum safe water level, the fusible plug shell loses its cooling function and is directly exposed to the furnace's high temperature (800-1200°C) or superheated steam (250-350°C). Heat is rapidly transferred through the shell to the melt.

Protection triggering: When the melt reaches its melting point (typically 230-330°C), completely melting within 3-5 minutes, forming a pressure relief hole with a diameter of 5-10mm.

Self-protection closed loop: High-pressure steam is ejected at high speed through the pressure relief hole, removing heat from the furnace and rapidly cooling the furnace body temperature (typically to a safe temperature within 10-15 minutes). Furthermore, the reaction force generated by the steam ejection slightly suppresses the furnace flame and simultaneously sounds an alarm, prompting the operator to shut down the boiler, add water, and replace the fusible plug until the fault is resolved and the boiler can be restarted.

The application of fusible plugs must be precisely tailored to the fuel type and operating conditions of the industrial boiler. Key applications include:

Pulverized coal boilers: As core safety components, fusible plugs are installed in the furnace roof and waterwall lower header. Pulverized coal boilers have extremely high furnace temperatures, reaching over 1500°C. During pulverized coal combustion, localized high-temperature zones easily form, posing a significant threat to the safe operation of the waterwall tubes. Fusible plugs, with their sensitive temperature sensing properties, can quickly respond to localized dry-burning risks in water-wall tubes, releasing pressure before danger occurs, effectively preventing tube bursts and ensuring stable operation of the entire boiler system. Furthermore, regular inspection of the integrity and response sensitivity of fusible plugs is crucial for the safety management of pulverized coal boilers, further reducing production interruptions and safety hazards caused by equipment failures.

Fire-tube boilers: Fusible plugs are essential components of fire-tube boilers, typically with one or two flame-operated fusible plugs installed on the furnace roof. For some large fire-tube boilers with evaporation rates exceeding 10 t/h, additional fusible plugs are installed on both sides of the furnace shell to provide more comprehensive "multi-point protection," covering critical overheating areas within the furnace. This multi-point arrangement enables more accurate monitoring of temperature changes in different parts of the furnace. In actual operation, the heat transfer process within fire-tube boilers is complex, and temperature distribution varies across different areas. Multi-point installation of fusible plugs ensures that any localized overheating event occurs, quickly triggering the protective mechanism and preventing serious accidents such as furnace damage or even explosion.

Oil and gas boilers: Steam-activated fusible plugs are preferred for safety considerations and should be installed in the steam space. While the flame combustion of oil and gas boilers is relatively stable, the potential risk of oil mist and gas leaks can lead to localized overheating. The ingenious design of steam-activated fusible plugs prevents false triggering from direct flame contact while maintaining high sensitivity to the risk of overheating. When the steam temperature exceeds a set threshold, the fusible plug's molten material rapidly melts, releasing steam pressure and effectively controlling the temperature rise. Furthermore, the precise location of fusible plugs in oil and gas boilers ensures real-time monitoring of critical temperature changes in the steam space, providing a reliable defense for safe boiler operation.

High-risk industrial environments: In chemical and metallurgical workshops, where flammable and explosive materials are involved, boiler fusible plugs face even stricter safety requirements. They require an "explosion-proof" enclosure, such as a thickened brass casing. This specialized material not only withstands higher pressures but also effectively prevents static sparks generated by steam ejection, preventing the combustion or explosion of surrounding flammable and explosive materials. Furthermore, to ensure earlier protection, the melting point of the fusible plug material in high-risk environments is lowered by 10-20°C. This design optimization allows the fusible plug to activate promptly at the slightest abnormal temperature rise, initiating safety measures before potential danger escalates, maximizing personnel safety and the integrity of production facilities, and reducing the risk of chain reactions caused by boiler overheating.

During the long-term operation of industrial boilers, fusible plugs are susceptible to various malfunctions due to the operating environment, directly impacting their safety and protection functions. Key issues include:

Corrosion leading to shortened service life: Substandard boiler water quality (e.g., excessive hardness or excessive oxygen content) can easily cause electrochemical corrosion on the fusible plug housing (e.g., pitting and dezincification of the brass housing), leading to reduced thickness, decreased strength, and even leakage. Corrosion can also form an oxide layer on the contact surface between the melt and the housing, impairing heat transfer efficiency and causing delayed triggering.

Scale and soot accumulation lead to thermal insulation: During operation, industrial boilers are prone to scale (primarily composed of calcium carbonate and magnesium sulfate) on the water side and soot accumulation on the smoke side (particularly severe in pulverized coal boilers). If scale or soot adheres to the surface of the fuse plug, it forms an insulating layer that hinders heat transfer. Even if the water level is too low, the melt will not reach its melting point in time, resulting in delayed protection or even complete failure.

Fuse aging leads to decreased sensitivity: When exposed to high temperatures for a long time (even before reaching its melting point), the melt will experience metal grain growth and oxidation deterioration, raising its melting point (for example, a tin-based melt operating at 150°C for a long time may see its melting point rise by 10-15°C). This can cause the fusible plug's trigger temperature to deviate from the designed value, preventing it from operating within the safety threshold.

Inspection may reveal leaks or looseness: Vibrations and temperature fluctuations during industrial boiler operation can loosen the threaded connection between the fusible plug and the furnace body, leading to steam leakage. Furthermore, aging or damage to the gasket during fuse plug installation can also lead to chronic leakage, affecting not only boiler thermal efficiency but also localized cooling of the fuse plug, affecting triggering sensitivity.

To ensure the safety and reliability of fusible plugs, industrial users must strictly adhere to maintenance and replacement specifications. Regarding replacement and inspection, according to the ASME Boiler and Pressure Vessel Code, the maximum service life of fusible plugs shall not exceed one year, and replacement is mandatory during the annual boiler inspection. In addition to annual replacement, a special inspection is required after each boiler overhaul (typically every three to six months) and furnace cleaning to confirm whether the plugs are leaking, loose, have corroded casings, and have scale or soot deposited on the surface. Key maintenance measures include cleaning furnace soot with high-pressure air purging or mechanical scraping, and removing scale on the water side of the plugs with an acid pickling agent that meets boiler water quality standards. The condition of the melt is assessed by visual inspection (if the casing is transparent or translucent) or weight testing. Any blackening or cracking of the melt requires immediate replacement.

Furthermore, a log of fusible plug installation, maintenance, and replacement is required, recording information such as model, melting point, replacement date, and operator to ensure traceability. Maintenance records should be retained for at least three years to meet regulatory inspection requirements and ensure the safe and compliant operation of industrial boilers. It is also recommended that data records of fusible plug operating conditions, such as temperature and pressure, be added to the ledger to facilitate analysis of performance trends. Newly replaced fusible plugs must undergo a leak-proof seal test before commissioning, using a hydrostatic test to ensure no leaks. Furthermore, differentiated fusible plug inspection plans should be developed for boilers operating under different conditions. For example, high-temperature and high-pressure boilers can have their inspection cycle shortened to monthly to strengthen preventive maintenance measures.

The selection of fusible plugs for industrial boilers requires comprehensive consideration of multiple factors. In accordance with the directive, I will convert the bullet points into H3 subheadings, with detailed explanations under each subheading to ensure completeness and enhance readability.

The selection of fusible plugs for industrial boilers must first be based on the boiler's design parameters. The fusible plug's shell material and structure must be determined based on the boiler's rated pressure, rated temperature, and furnace material. For high-pressure boilers (>9.8 MPa), to prevent the shell from rupturing due to excessive pressure, a thickened brass shell with a thickness of ≥5 mm should be used. Flame-operated fusible plugs should be used for fire-tube boilers, while steam-operated plugs are preferred for water-tube boilers. This ensures that the fusible plugs are precisely matched to the boiler's basic design parameters.

Matching the melting point temperature with the boiler's operating parameters is crucial for boiler selection. The melting point of the molten material must be 50-100°C lower than the boiler's "dangerous overheat temperature." For example, for a carbon steel fire-tube boiler rated at 1.0 MPa, the dangerous overheat temperature is approximately 350°C. A tin-lead alloy with a melting point of 230-280°C should be selected. For a high-pressure boiler rated at 10 MPa, the dangerous overheat temperature is approximately 450°C. A lead-bismuth alloy with a melting point of 320-350°C can be selected. By precisely controlling the melting point, the fusible plug protection mechanism is triggered promptly in the event of abnormal overheating.

Fusible plug selection must strictly adhere to manufacturer and standard requirements. Fusible plug models recommended by the boiler manufacturer should be preferred, ensuring that the plug dimensions, such as thread size and length, match the furnace mounting holes. Furthermore, products that comply with international standards (such as ASME B16.37) must be selected to avoid using unqualified, non-standard products. This ensures the safety of the fusible plug from the source and prevents safety hazards caused by substandard products.

Operating condition adaptability is also a crucial factor in fusible plug selection. In highly corrosive environments, such as chemical boilers with acidic or alkaline water, fusible plugs with bronze or stainless steel casings should be selected for enhanced corrosion resistance. In environments subject to high vibration, such as marine and mobile boilers, fusible plugs with locknuts should be selected to prevent loosening during operation and ensure the fusible plugs can maintain their safety protection function even under complex operating conditions.

In the safe operation system of industrial boilers, fusible plugs, despite being simple passive devices, fulfill the dual roles of overheating risk monitors and explosion preventers. Through precise temperature response and autonomous protective action, they complement the safety valve's blind spot against overheating risks and are an irreplaceable component for ensuring the safety of boiler equipment and operators.

Industrial production practice shows that over 80% of boiler overheating accidents are caused by improper maintenance or untimely replacement of fusible plugs. Therefore, regular inspections (every 3-6 months), mandatory annual replacement, and standardized maintenance records are key to ensuring the effectiveness of fusible plugs and are fundamental requirements for industrial users to achieve safe production.

Industrial boiler users must fully understand the safety value of fusible plugs and strictly adhere to standards and specifications such as ASME and GB. They must manage the entire lifecycle of fusible plugs, from selection to installation, maintenance, and replacement, to avoid major safety incidents caused by minor component neglect. Ultimately, this ensures the long-term stable and safe operation of boiler equipment and provides a solid guarantee for the continuity of industrial production.