In industrial boiler systems, boiler fans are critical auxiliary equipment for maintaining stable combustion and ensuring efficient boiler operation. They function like the system's "breathing system," directly impacting the boiler's thermal efficiency, operational safety, and environmental performance. This article, focusing on industrial boiler scenarios, comprehensively explains the core knowledge of boiler fans, including their definition, function, operating principle, types, efficiency relationships, energy-saving and environmental benefits, and maintenance.

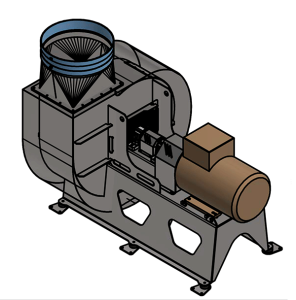

Boiler fans are specialized equipment used in industrial boiler systems for gas transportation and airflow regulation. They use a motor-driven impeller to convert mechanical energy into gas kinetic energy and pressure energy, enabling air and pulverized coal transportation or flue gas extraction. They are core components for ensuring boiler system operation. Compared to conventional ventilation equipment, they must adapt to complex operating conditions such as high temperatures and high dust levels, requiring high air pressure, wear resistance, and high-temperature resistance.

In industries such as chemical and metallurgy, boiler fans are essential throughout the entire boiler operation process: supplying combustion air and pulverized coal during the combustion preparation phase; maintaining stable furnace pressure during combustion; and extracting high-temperature flue gases during the flue gas treatment phase. For example, chemical steam boilers require precise air flow control to prevent coking, and building materials waste heat boilers must adapt to low-temperature environments to ensure efficient recovery.

In industrial boiler systems, four core fans work in tandem:

Primary air fan (PA fan): transports and dries pulverized coal, helping to form a flame core;

Secondary air fan (SA fan): replenishes combustion air, enhances mixing, and reduces incomplete combustion emissions;

Forced draft fan (FD fan): provides positive pressure air and distributes primary and secondary air volumes;

Induced draft fan (ID fan): extracts high-temperature flue gas and maintains a slight negative pressure in the furnace.

The combustion process in industrial boilers, especially pulverized coal combustion, requires a large amount of oxygen. Boiler fans deliver sufficient air to the furnace through the forced draft fan (FD) and secondary air fan (SA fan). The forced draft fan provides positive pressure air to establish a foundation for combustion, while the SA fan dynamically replenishes air based on furnace temperature and pulverized coal concentration to ensure adequate contact between oxygen and the pulverized coal. Insufficient air supply leads to incomplete combustion of pulverized coal, reducing boiler thermal efficiency and producing pollutants such as carbon monoxide (CO) and soot, even causing furnace coking. Conversely, an adequate air supply can improve combustion efficiency by 5%-10%, significantly reducing fuel consumption in industrial boilers.

In pulverized coal industrial boilers, the primary air fan (PA) is the core equipment for conveying and drying the pulverized coal. Firstly, the PA fan transports the pulverized coal from the silo to the burner at a specific air pressure, ensuring that the pulverized coal delivery rate matches the boiler load. Secondly, the air delivered by the PA fan removes moisture from the pulverized coal, improving its dryness and preventing wet coal from clogging the burner or affecting flame stability. Furthermore, the air delivered by the secondary air fan (SA) mixes with the pulverized coal at the burner outlet, forming a stable swirling flame and preventing flame deflection or extinguishing. This is crucial for the continuous operation of industrial boilers. An unstable flame can cause boiler load fluctuations and affect steam supply to downstream production processes.

The high-temperature flue gas generated by industrial boiler combustion contains large amounts of pollutants such as dust and SO₂. It must be extracted by induced draft (ID) fans and transported to the downstream dust removal and desulfurization systems for treatment. Crucially, the ID and FD fans work together to maintain a slightly negative pressure environment within the furnace. If the positive pressure in the furnace is too high, high-temperature flue gas may escape through gaps such as the furnace door and flanges, causing equipment corrosion and burns. If the negative pressure is too high, excessive cold air will be drawn in, lowering the furnace temperature and increasing fuel consumption. In industrial boilers, the negative pressure in the furnace is typically controlled between -50 Pa and -100 Pa. This precise control relies entirely on the matching air volume of the ID and FD fans. 2.4 Overall Significance for Efficiency and Safety

From an efficiency perspective, the air volume and air pressure regulation of boiler fans directly impacts boiler thermal efficiency. A reasonable air-to-coal ratio reduces incomplete combustion losses and exhaust heat loss, maintaining industrial boiler thermal efficiency above 85%. From a safety perspective, stable fan operation prevents equipment damage caused by positive furnace pressure explosions or excessive negative pressure. Furthermore, effective exhaust of flue gases by fans prevents flue gas accumulation within the furnace, avoiding safety incidents such as carbon monoxide poisoning, thereby ensuring the continuous and safe operation of industrial boilers.

In industrial boiler systems, airflow organization follows the core principle of "positive pressure push + negative pressure exhaust." The forced draft fan (FD), along with the primary air fan (PA) and secondary air fan (SA), forms the "positive pressure side." The rotating impellers work the air, imparting pressure and kinetic energy to the air, which is then transported to the furnace under positive pressure. The induced draft fan (ID) forms the "negative pressure side." Its rotating impellers create negative pressure at the furnace outlet, drawing the combusted flue gases out of the furnace and into the tail duct, ensuring unidirectional airflow within the boiler system, without dead ends or backflow.

Maintaining a slightly negative pressure in the furnace of an industrial boiler is essential for three main reasons: For safety, it prevents high-temperature flue gas leakage, high-temperature corrosion of equipment, and personnel accidents. For combustion stability, it maintains a steady flow within the furnace, preventing positive pressure from causing the flame to "stick to the wall" and cause coking, or excessive negative pressure from "cold air intrusion," which lowers the furnace temperature and disrupts combustion conditions. Furthermore, it protects the equipment by reducing the erosion of high-temperature gases on the refractory materials on the furnace roof and walls, extending their service life and reducing maintenance costs. During industrial boiler operation, loads fluctuate dynamically with downstream production demands, necessitating dynamic airflow balance in the system by adjusting the air volume and pressure of each fan. When boiler load increases, the FD fan, along with the PA and SA fans, must simultaneously increase air volume to ensure the oxygen and pulverized coal required for fuel combustion. The ID fan also needs to increase exhaust volume to prevent negative furnace pressure from becoming positive. When load decreases, the air volume of each fan is simultaneously reduced to ensure a stable negative furnace pressure between -50 Pa and -100 Pa. The key to dynamic airflow balance lies in "synchronous adjustment," otherwise boiler operation will be impacted.

3.2.1 Primary Air Fan (PA Fan): Pulverized Coal Transport, Coal Drying, and Flame Core Formation

In pulverized coal industrial boilers, the PA fan's operating process is divided into three stages: First, pulverized coal transport. The PA fan draws heated air from the air preheater and transports it through pipes to the bottom of the pulverized coal silo, where it "blows" the pulverized coal toward the burner. Second, pulverized coal drying. The preheated air absorbs moisture from the pulverized coal, preventing wet coal from agglomerating and clogging in the pipes. Third, flame core formation. After the air-coal mixture transported by the PA fan enters the burner, it forms an initial flame core within the furnace, laying the foundation for subsequent secondary air to supplement combustion. For example, in a 20t/h industrial pulverized coal boiler, the PA fan typically delivers an air volume of 15,000-20,000 m³/h at a pressure of 10-12 kPa to meet the requirements for pulverized coal transport and drying.

3.2.2 Secondary Air Fan (SA Fan): Supplementing Air, Enhancing Mixing, and Reducing Emissions

The SA fan's function revolves around enhancing combustion. Specifically, the SA fan draws air from the environment, heats it in an air preheater, and delivers it to the burner's secondary air nozzle. The secondary air is injected into the furnace at a specific angle, creating a swirling flow with the pulverized coal mixture carried by the PA airflow. This enhances the mixing of the air and coal. This process ensures complete combustion of the carbon in the pulverized coal, reducing CO and soot emissions. Furthermore, the swirling effect of the secondary air lengthens the flame, preventing it from concentrating in the center of the furnace and causing localized overheating and coking. In industrial boilers, the SA air volume is typically 2-3 times that of the PA air. For example, if the PA air volume is 20,000 m³/h, the SA air volume can reach 40,000-60,000 m³/h to ensure sufficient oxygen.

3.2.3 FD Fan: Provides Positive Pressure Air and Distributes Primary and Secondary Air

The FD fan is the "main air source" for the industrial boiler system. Its operation is highly coordinated: the FD fan draws clean air from outside the boiler building, delivering a portion directly to the air preheater and another portion directly to the furnace as needed. Simultaneously, the FD fan adjusts the air pressure and air volume via outlet dampers and a frequency converter to achieve the proper distribution of primary and secondary air. For example, when the boiler load increases, the FD fan increases the total air volume while simultaneously adjusting the opening of the PA and SA air dampers to maintain a constant air-to-coal ratio and secondary air ratio. In industrial boilers, the FD fan's air volume must match the boiler's rated evaporation capacity. For example, for a 10t/h industrial boiler, the FD fan's rated air volume is typically 80,000-100,000m³/h, with an air pressure of 5-7kPa. 3.2.4 Induced Draft Fan (ID Fan): Extracts Flue Gas and Maintains Negative Furnace Pressure

ID fans must cope with the complex operating conditions of high temperature and high dust. The specific process is as follows: High-temperature flue gas generated by combustion in the furnace first enters the convection tube bundle for cooling before being drawn into the tail flue by the ID fan. During the extraction process, the ID fan must overcome resistance in the furnace, the convection tube bundle, the dust removal system, and the desulfurization system. Therefore, ID fans are typically designed for high air pressure. Furthermore, the ID fan adjusts the exhaust volume via an inlet damper and a frequency converter, working in conjunction with the FD fan to maintain a slight negative pressure in the furnace. When the negative pressure in the furnace is too low, the ID fan increases the exhaust volume; when the negative pressure is too high, the exhaust volume is reduced. Furthermore, ID fans in industrial boilers are typically equipped with wear-resistant impellers to prevent dust erosion in the flue gas and extend their service life.

The "push-pull" synergistic mode of industrial boiler fans is the core of stable system operation. Specifically, it is as follows:

The FD fan "pushes" air circulation: The FD fan acts as the "push source," pushing air to the air preheater for heating. It then distributes air to the PA and SA fans, ultimately delivering it to the furnace, providing the "power foundation" for combustion.

The ID fan "pulls" flue gas emissions: The ID fan acts as the "pull source," creating negative pressure at the furnace outlet, "pulling" the combusted flue gas out of the furnace. After passing through the tail flue, dust removal, and desulfurization systems, the flue gas is discharged through the chimney to meet standards.

The PA/SA fans "coordinate" the combustion process: The PA fan transports pulverized coal and initial air, while the SA fan supplements combustion-supporting air. These two fans form a "swirl mixing zone" at the burner outlet, ensuring sufficient combustion of the pulverized coal. This, combined with the FD fan's total air volume regulation, achieves As the amount of pulverized coal increases, the air volume also increases.

The system forms a closed-loop cycle: air enters through the FD fan, is burned and converted into flue gas, and then exhausted by the ID fan. The entire process forms a closed loop of "air → combustion → flue gas → exhaust." Each fan is coordinated and regulated via the distributed control system. For example, when the DCS detects that the furnace negative pressure deviates from the set value, it simultaneously adjusts the air volume of the FD and ID fans to ensure that the negative pressure quickly returns to a stable range. This coordinated mode controls airflow fluctuations in industrial boilers to within ±5%, maintaining a high level of combustion efficiency.

The combustion efficiency, furnace safety, energy consumption, and environmental performance of industrial boilers are closely related to fan operating parameters. The "air-to-coal ratio" and "secondary air ratio" play a decisive role in combustion efficiency. Insufficient PA air volume reduces pulverized coal transport and leads to inadequate drying, while insufficient SA air volume prevents adequate mixing of air and pulverized coal. Both lead to incomplete combustion and reduced thermal efficiency. Excessive total air volume, on the other hand, increases exhaust gas temperature and fan energy consumption. For example, a chemical company adjusted the PA/SA air ratio of a 20 t/h industrial boiler from 1:2 to 1:2.5, increasing combustion efficiency from 88% to 92%, saving approximately 150 tons of coal annually.

Regarding furnace safety, excessive FD fan volume and insufficient ID fan volume can increase furnace positive pressure. When the air-to-coal mixture reaches the explosive limit, it can cause deflagration upon contact with an open flame. Excessive negative furnace pressure draws in cold air, interrupting pulverized coal combustion and even causing flashback. Furthermore, excessive positive pressure can cause high-temperature flue gas to leak, threatening equipment and personnel safety. Therefore, stable fan operation is crucial to ensuring furnace safety.

In terms of energy consumption, fans account for 60%-80% of a boiler's total electricity consumption. Due to their high air pressure and high power, ID and FD fans can consume 100-500kW per motor. If fan operating parameters are mismatched with boiler load, energy consumption can increase significantly. For example, a 15t/h industrial boiler at a building materials company consumed approximately 800,000 kWh of electricity per year under constant speed operation before retrofitting. After converting to variable frequency operation, this consumption was reduced to 500,000 kWh, a 37.5% energy saving.

In terms of environmental performance, fan operating parameters directly impact pollutant emissions. The SA fan's sufficient air supply can reduce CO emission concentration from 2000mg/m³ to below 50mg/m³. By adjusting the position and angle of the secondary air supply, "staged air supply" can reduce the local temperature of the furnace and reduce NOx emission concentration from 500mg/m³ to below 200mg/m³. The ID fan's stable exhaust ensures that all flue gas enters the dust removal system, keeping the dust emission concentration below 10mg/m³.

PA fans are specialized fans used for conveying and drying pulverized coal in industrial boilers. Their key features include: 1. High air pressure design, which must overcome resistance in the pulverized coal piping, silo, and burner. Air pressure is typically 8-15 kPa. 2. High temperature resistance. Because the inhaled air is heated by an air preheater, the fan impeller and casing must be made of high-temperature resistant materials. 3. Anti-clogging design. The fan inlet is typically equipped with a filter and dust removal device to prevent pulverized coal particles from entering the fan and causing blockage. In industrial applications, PA fans are mostly centrifugal, while some large industrial boilers use axial-flow PA fans.

The core function of an SA fan is to supply combustion air. Its characteristics are: First, a high air volume design, typically 2-3 times that of a PA fan, to meet the oxygen requirement for full combustion of pulverized coal. The rated air volume of an SA fan for industrial boilers can reach 40,000-100,000 m³/h. Second, high adjustability. An adjustable damper or frequency converter is installed at the fan outlet, dynamically adjusting the air volume based on furnace temperature and pulverized coal volume, achieving "precise air delivery." Third, a low-noise design. Because SA fans generate high noise levels due to their high air volume, industrial applications require silencers and soundproofing enclosures to keep noise levels below 85dB. SA fans are also primarily centrifugal. Some small and medium-sized industrial boilers use mixed-flow SA fans to balance air volume and air pressure.

As the "main air source" for industrial boilers, FD fans have the following characteristics: First, they are highly coordinated, providing air for the PA fan, SA fan, and tertiary air fan, with air volume matching the rated load of the boiler. Second, they offer moderate air pressure, typically 3-8 kPa at the outlet. They must overcome resistance in the air preheater and ducting, while also providing sufficient inlet pressure for the PA and SA fans. Third, they offer high reliability. FD fans are often configured with one active and one standby. If one fan fails, the backup fan can start within 10-15 seconds, ensuring continuous boiler operation. FD fans are primarily centrifugal in design, while large industrial boilers employ axial-flow FD fans, achieving efficiencies exceeding 85%.

ID fans are core equipment for industrial boilers dealing with high-temperature, high-dust flue gases. Their characteristics are: First, they require high air pressure and high-temperature resistance. They must overcome the combined resistance of the flue, dust removal, and desulfurization systems, while simultaneously withstanding flue gases at temperatures of 800-1000°C. Therefore, the fan impeller is made of wear-resistant and high-temperature resistant alloy materials, and the casing is water- or air-cooled. Second, they are designed to resist wear. Flue gases contain a large amount of dust, so the impeller surface is sprayed with a wear-resistant coating. A cyclone separator is installed at the fan inlet to pre-process some of the dust, extending the impeller's service life. Third, they are designed to be high-powered. ID fan motors typically have power levels of 200-500kW. Some large industrial boilers use two-stage centrifugal ID fans to further increase air pressure.

In industrial boilers, insufficient PA fan air volume reduces pulverized coal delivery and inadequate pulverized coal drying , making it difficult to ignite upon entering the furnace, resulting in a "black flame" . Insufficient SA fan air volume prevents adequate mixing of air and pulverized coal, leading to localized oxygen deficiency and only partial combustion of the carbon in the pulverized coal, reducing combustion efficiency. It has been calculated that for every 10% reduction in PA air volume, boiler thermal efficiency decreases by approximately 2%, while for every 10% reduction in SA air volume, thermal efficiency decreases by approximately 1.5%. Furthermore, incomplete combustion can lead to furnace coking , further reducing boiler heat transfer efficiency, creating a vicious cycle of "reduced efficiency - coking - further reduced efficiency."

If the total air volume of the FD fan is too large (or the ratio of the PA and SA air volumes is unbalanced), a large amount of cold air will enter the furnace. Although there is sufficient oxygen, the excess air will remove heat from the furnace, causing the exhaust temperature to rise. For example, when the excess air coefficient (the ratio of actual air volume to theoretical air volume) increases from 1.2 to 1.5, the exhaust temperature will rise from 150°C to 180°C. For every 10°C increase in exhaust temperature, the boiler's thermal efficiency decreases by approximately 0.5%. Furthermore, excess air increases the exhaust load of the ID fan, increasing its energy consumption (for every 10% increase in exhaust volume, the ID fan's power consumption increases by approximately 20%), further reducing the boiler's overall energy efficiency (boiler efficiency requires a comprehensive consideration of both thermal efficiency and power consumption).

When the boiler fan air volume is precisely matched to the boiler load and fuel characteristics (i.e., a reasonable air-to-coal ratio and an appropriate secondary air ratio), the boiler achieves optimal thermal efficiency. At this point, the pulverized coal is fully burned (CO emissions are below 50mg/m³), the exhaust gas temperature is controlled between 120-150°C (below the industry average), and the excess air coefficient is maintained between 1.1-1.2 (the most economical range). For example, a chemical company's 20t/h industrial boiler, through coordinated DCS control of the air volume of each fan, maintained an air-to-coal ratio of 2.0 and a secondary air ratio of 65%, increased boiler thermal efficiency from 88% to 92%, saving approximately 200 tons of standard coal annually, resulting in significant economic benefits.

Traditional industrial boiler fans often use a "constant-speed motor + damper adjustment" approach to control air volume. Damper throttling results in significant energy loss. Variable frequency fans, on the other hand, vary air volume by adjusting motor speed, eliminating throttling losses and achieving efficiencies of 80%-90%. According to industry data, retrofitting industrial boiler fans with variable frequency drives generally results in energy savings of 30%-50%. If all industrial boiler fans nationwide were retrofitted with variable frequency drives, approximately 10 billion kWh of electricity could be saved annually . Furthermore, variable frequency control reduces fan starting current, minimizing impact on the power grid and extending motor life.

Refined air volume control of each fan through the DCS system can further reduce power consumption. For example, when the boiler load drops from 100% to 50%, the DCS system will simultaneously reduce the speed of the FD fan, proportionally adjust the speeds of the PA and SA fans, and simultaneously reduce the speed of the ID fan. This "load-linked regulation" mode avoids running a single fan at full load, reducing total fan power consumption linearly with load. A construction materials company has demonstrated that implementing refined air volume control reduced total fan power consumption by approximately 25% within the 50%-100% boiler load range, significantly exceeding the energy savings achieved with simple frequency conversion. 6.3 Secondary Air Distribution and NOx Reduction

NOx emissions from industrial boilers primarily consist of thermal NOx and fuel NOx . Thermal NOx accounts for approximately 60%-70%. The SA fan's "staged air supply" can lower local furnace temperatures and simultaneously create a "reduction zone" . For example, a chemical company reduced NOx emissions from 450mg/m³ to 180mg/m³ by optimizing the SA air stage, meeting the national ultra-low emission standard. This eliminates the need for additional denitrification equipment and reduces environmental investment.

Industrial boiler dust removal and desulfurization systems require a stable flue gas flow rate to function effectively. If the ID fan's exhaust volume is insufficient, flue gas will accumulate in the furnace and be unable to enter the dust removal/desulfurization system, resulting in direct dust and SO₂ emissions exceeding standards. Excessive fluctuations in exhaust volume can damage filter bags in the dust collection system or cause unstable electric field voltage, reducing dust removal efficiency. ID fans ensure stable exhaust flow by matching the flue gas flow rate with the design flow rate of the dust removal/desulfurization system , thereby controlling dust emission concentrations below 10 mg/m³ and SO₂ emission concentrations below 35 mg/m³ . In addition, ID fans can adjust the airflow rate to cope with changes in resistance in the dust removal/desulfurization system.

Industrial boiler fans often experience bearing overheating, impeller dust accumulation, fan vibration, and motor overload. Long-term high-speed operation of bearings at 1500-3000 rpm and high temperatures, coupled with insufficient lubrication, grease deterioration, or installation errors, can increase friction, causing temperatures exceeding the normal range of 70°C and, in severe cases, causing the unit to seize and shut down. The impellers of ID and PA fans are susceptible to dust accumulation due to flue gas dust and wet coal dust, leading to dynamic imbalance, reduced airflow, and severe vibration. Fan vibration can also be caused by impeller wear, bearing damage, coupling misalignment, or foundation settlement. Vibration exceeding 11.2 mm/s can endanger equipment stability. Motor overload is often caused by sudden damper opening, pipe blockage, or impeller dust accumulation, resulting in current exceeding the rated value. Prolonged overload can burn the motor.

To address these issues, regular maintenance measures such as cleaning, dynamic balancing, bearing lubrication, and current monitoring are necessary. PA and ID fans should be cleaned monthly, using compressed air or a wire brush to remove impeller dust, and the pipes should be unblocked. If fan vibration exceeds 8.5 mm/s, remove the impeller and use a dynamic balancing machine to calibrate it. Repair worn areas and then rebalance. Bearing lubrication should adhere to the principles of "regular, quantitative, and qualitative" lubrication. Use lithium-based grease with a temperature resistance of 120°C or higher every 2000 hours or monthly, filling 1/3 to 1/2 of the bearing's internal space. Check the grease condition regularly. Monitor the current in real time through the DCS system or an ammeter, maintaining it between 80% and 100% of the rated current. Troubleshoot any abnormal increases, and record and analyze data weekly.

Boiler fans, as the "breathing system" of industrial boilers, are central to ensuring combustion and environmental protection. The forced draft fan and induced draft fan work together to control a slight negative pressure in the furnace, ensuring safety. The primary and secondary fans adjust the air-to-coal ratio, improving combustion efficiency and reducing emissions. Frequency conversion reduces energy consumption.

In actual operation, optimizing fan parameters can achieve boiler thermal efficiency exceeding 85%. Strengthening maintenance and management can reduce failures and extend boiler life. In the future, as industrial boilers evolve toward higher efficiency and ultra-low emissions, boiler fans will be upgraded to higher efficiency, smarter operation, and lower energy consumption, becoming key to energy conservation and carbon reduction.