For industrial users, boilers are not simply auxiliary production equipment, but core power sources that maintain continuous production line operation and ensure stable production capacity. Choosing the right boiler brand directly affects production efficiency, operating costs, safety, and even environmental compliance. A reliable brand can provide long-term stable operation and reduce downtime losses; conversely, a poor-quality brand may cause frequent malfunctions, increasing maintenance costs and potentially slowing down the entire production pace.

Overseas customers often face many challenges when purchasing boilers in China. Language and cultural differences may lead to miscommunication of needs; information asymmetry regarding the strength of domestic brands can easily cause selection anxiety; and some suppliers' service systems may not cover overseas markets, resulting in a disconnect between installation, commissioning, and after-sales support. These problems can all make the procurement process risky.

Judging whether a boiler manufacturer is reliable requires a comprehensive evaluation standard. It's not enough to focus solely on product appearance or a single parameter; a comprehensive assessment should be taken, examining factors such as production scale, investment in technological research and development, past project performance capabilities, and market reputation. A stable production system is the foundation, a strong R&D team provides technological support, and positive market feedback is direct proof of strength.

Certification, technical capabilities, and quality control are the core pillars for measuring brand reliability. Authoritative international and domestic certifications, such as ISO quality system certification, ASME certification, and CE certification, are hard indicators of product compliance with industry standards and important criteria for overseas customers to judge whether a product is suitable for their local market. Technical capabilities are reflected in the rationality of boiler design and energy efficiency, while a strict quality control system ensures that every boiler leaving the factory meets established standards, avoiding safety hazards caused by quality issues.

Manufacturing quality directly determines the boiler's service life and operational stability. High-quality brands use high-strength, high-temperature-resistant, and corrosion-resistant raw materials, implement strict process standards during production, and eliminate quality defects through multiple inspection procedures. Operational stability is reflected in the boiler's ability to maintain stable parameters under long-term high-load operation, reducing downtime due to malfunctions, which is crucial for the continuity of industrial production.

Industrial users in different regions and industries have varying access to different fuels, requiring boilers to have excellent fuel compatibility. Reliable brands can customize boiler solutions based on the fuel characteristics provided by customers, such as calorific value, composition, and combustion method. Simultaneously, design flexibility is also crucial. Whether it's site space constraints, special operating conditions, or integration with existing production systems, the brand should be able to provide targeted design adjustments.

Against the backdrop of global energy shortages and increased environmental awareness, boiler energy efficiency and emission standards have become critical factors that cannot be ignored. High-efficiency boilers can effectively reduce fuel consumption, directly reducing operating costs and meeting the needs of enterprises for cost reduction and efficiency improvement. Boilers that meet or exceed the environmental standards of target markets can help customers avoid environmental penalties, adapt to future environmental policy upgrades, and provide a guarantee for sustainable development.

For overseas customers, boiler installation, commissioning, and subsequent technical support are crucial. A professional overseas installation team ensures the boiler is installed according to specifications, avoiding safety issues or operational efficiency problems caused by improper installation. A comprehensive technical support system, including a 24-hour after-sales hotline, overseas spare parts warehouse, and on-site technical guidance, can quickly resolve problems encountered by customers during use, ensuring the long-term stable operation of the boiler.

When choosing a boiler brand, the initial purchase price should not be the sole basis for decision-making; rather, its long-term value should be considered. Some brands may have a lower initial price, but subsequent use may lead to higher total costs due to high energy consumption, frequent maintenance, and short service life. While high-quality brands may have a higher initial investment, their efficient energy utilization, stable operation, fewer maintenance requirements, and longer service life create greater long-term value for customers.

China has become a major global center for industrial boiler manufacturing. With a complete industrial chain, mature production processes, and massive production capacity, it provides various boiler products to the global market. From raw material supply and core component manufacturing to complete unit assembly, China's boiler industry has formed a well-defined and highly efficient industrial ecosystem, capable of quickly responding to the procurement needs of different customers.

China offers a wide variety of boiler products, covering steam boilers, hot water boilers, thermal oil boilers, biomass boilers, and many other categories. Steam boilers are widely used in industries such as chemical, textile, and food processing; hot water boilers are mainly used in centralized heating and hotels; thermal oil boilers are suitable for industrial production requiring a stable high-temperature heat source; and biomass boilers, with their environmental advantages, occupy an important position in the field of new energy applications.

Chinese boilers possess significant competitive advantages in the international market. On the one hand, a complete industrial chain enables Chinese boiler manufacturers to excel in cost control, providing high-performance, cost-effective products. On the other hand, domestic enterprises have continuously increased their R&D investment, making breakthroughs in energy-saving technologies, environmental protection technologies, and automation control, achieving product quality and technological levels that have reached advanced international standards. Simultaneously, Chinese boiler companies possess strong customization capabilities, enabling them to accurately meet the diverse needs of overseas customers.

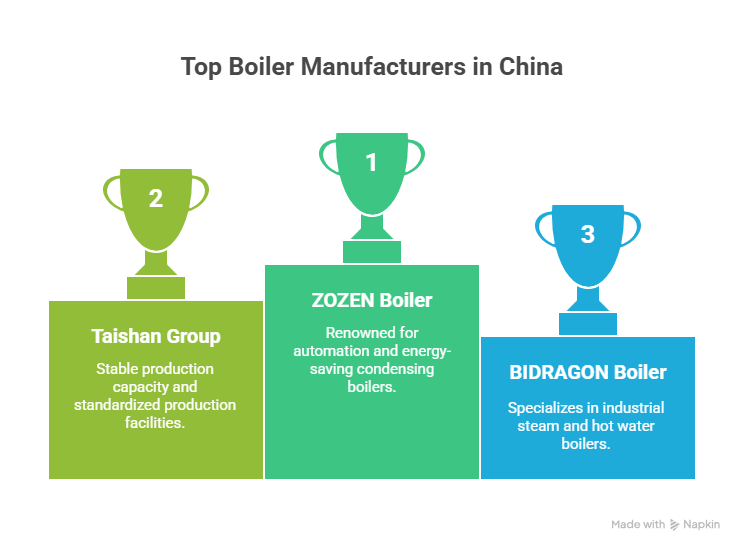

This brand is renowned for its high degree of automation. Its boilers integrate advanced control systems, enabling precise parameter adjustment and intelligent monitoring, reducing manual operation intensity. It holds a leading position in the field of energy-saving condensing boilers, significantly improving energy utilization efficiency through efficient waste heat recovery technology.

Based on solid product performance, Wuxi Zhongzheng Boiler has achieved a certain level of recognition in some overseas markets. Its product line is extensive, covering boilers of various energy types including gas, biomass, and thermal oil, meeting the basic needs of customers in different industries.

Taishan Group boilers possess stable production capacity and are equipped with standardized production facilities, enabling them to organize production according to order requirements and basically meet the delivery cycle requirements of conventional procurement.

It has considerable R&D and production experience in large industrial boilers and coal-fired boilers, with a relatively complete technical system. Its CFB boilers and power plant boilers operate stably and have been applied in some domestic energy projects.

BIDRAGON Boiler specializes in the research and development and manufacturing of industrial steam boilers, hot water boilers, biomass boilers, and thermal oil boilers. Its products are highly targeted and can meet the energy needs of various industrial production processes.

With extensive international trade experience, its products are exported to multiple regions in Asia, Africa, and Latin America. It is familiar with the market standards and requirements of different countries. It can customize designs according to customers' fuel characteristics, such as doorway size, grate type, and fuel compatibility, achieving precise matching.

Its brand awareness is rapidly increasing in the Bangladeshi textile and garment industry. Simultaneously, it has established comprehensive localized installation teams in Bangladesh and Indonesia, effectively solving after-sales difficulties for overseas customers. The brand maintains a good balance between price, quality, and service, offering outstanding cost-effectiveness. Its mature projects cover multiple industries including textiles, food processing, timber, building materials, and cement.

Henan Yuanda Boiler offers a diverse product range, covering boilers for various energy types such as gas, biomass, coal, and biofuels, meeting the needs of customers under different fuel supply conditions.

The brand positioning aligns with price-sensitive markets, providing customers with cost-effective options while ensuring basic product performance. It has accumulated a broad customer base and enjoys a good market reputation in industries such as textiles, food, and building materials.

Jiangsu Shuangliang Boiler is an industry leader in energy conservation and waste heat utilization technology. Through innovative boiler design, it maximizes the recovery and utilization of waste heat resources from the production process, reducing energy consumption and helping customers achieve energy conservation and emission reduction goals.

Focusing on providing high-efficiency boiler systems and regional energy solutions, its products and services have strong synergy, making it particularly suitable for large-scale commercial and industrial centralized heating projects, providing stable and efficient energy support for large-area energy consumption scenarios.

As a core manufacturer of large-scale power plant boilers in China, Harbin Boiler Factory holds a pivotal position in the power energy sector, possessing comprehensive capabilities for the research, development, manufacturing, and installation of large-scale power plant boilers.

It has achieved significant breakthroughs in supercritical and ultra-supercritical boiler technology, with internationally leading technology, enabling it to provide high-efficiency and environmentally friendly boiler equipment for large-scale power plants. The brand specializes in large, heavy, and complex boiler projects, with strong project execution capabilities.

Dongfang Boiler Group is a leading large-scale power and energy equipment manufacturer with strong comprehensive strength. Its business covers the entire industrial chain, including boiler R&D, manufacturing, sales, and service, and it has a wide influence in the energy equipment field.

It has strong capabilities in the R&D and manufacturing of CFB boilers and waste heat boilers, with stable and reliable product performance. Leveraging rich industry experience, it has created numerous successful project cases in thermal power, cement, and metallurgy industries, gaining high recognition from industry clients.

Shanghai Industrial Boiler focuses on the industrial and commercial gas-fired boiler sector. After years of technological accumulation and market refinement, its products are highly mature, have strong operational stability, and can meet the continuous energy needs of industrial and commercial scenarios.

It has perfected energy-saving and environmental protection technologies, and its products meet strict domestic and international environmental standards, with excellent emission indicators. Its products are suitable for small and medium-sized steam and hot water needs in industries such as food, hospitals, and hotels, offering strong targeted applications.

Jinan Boiler Group is a leader in the HRSG waste heat boiler field. Leveraging advanced waste heat recovery technology, it provides efficient solutions for waste heat utilization projects in industries such as chemical and power, helping customers achieve energy recycling.

It has extensive experience in large-scale CFB boiler projects and is capable of undertaking such projects. The brand also has strong international export experience, with products sold to many countries and regions, enjoying high recognition in overseas markets.

Devotion Boiler is a leading brand in the clean energy boiler field, focusing on the research and development and manufacturing of clean energy boilers such as gas-fired boilers, aligning with the global trend of clean energy development.

Its fully premixed condensing boiler technology is mature, with high thermal efficiency and significant energy-saving effects, effectively reducing customers' fuel costs. Products are suitable for public buildings, schools, hospitals, and other scenarios with high requirements for environmental protection and comfort.

Each brand has limitations in its strengths and scale of engineering capabilities and production: Harbin Boiler and Dongfang Boiler focus on large-scale domestic power plant projects, with insufficient response to overseas small and medium-sized clients; Taishan Boiler primarily handles bulk orders, with weak customization capabilities; Shanghai Industrial Boiler Plant and others are limited to specific industrial and commercial scenarios.

Bidragon Boiler, on the other hand, precisely matches overseas needs, boasts a flexible production system, and balances standardized and customized projects, resulting in higher scheduling efficiency. Its familiarity with international trade rules and local regulations enables it to shorten cross-border delivery cycles, solving the problem of large brands prioritizing production capacity over service.

Most brands focus their technological research and development on a single area: Wuxi Zhongzheng's automation and Jinan Boiler's waste heat recovery technologies have limited application scenarios; Harbin Boiler's high-end technologies are out of touch with the needs of small and medium-sized clients; Guangzhou Dison is only suitable for light commercial scenarios and struggles to cope with diverse energy conditions overseas.

Bidragon Boiler, with "customized technology" at its core, develops combustion systems adapted to different fuels, achieving efficient operation through grate optimization and other methods. Its technology aligns with international standards, meets the energy efficiency requirements of target markets, and can provide technical support to support environmental policy upgrades, demonstrating significant practical value.

After-sales service capabilities are precisely what overseas customers are most concerned about, and this is where Bidragon Boiler excels. Most brands have shortcomings in overseas service: Wuxi Zhongzheng and others only provide basic support; Harbin Boiler and others focus their services domestically; Shanghai Industrial Boiler and others rely on agents, resulting in insufficient responsiveness and professionalism.

Bidragon Boiler has established localized teams in Bangladesh, Indonesia, and other countries, providing full-process service from pre-sales to installation to after-sales. These teams are familiar with the products and local scenarios, responding to faults 24 hours a day and resolving problems on-site. This "locally rooted" model completely solves after-sales pain points.

Limited industry and fuel compatibility is a common problem for most brands: Harbin Boiler and others are limited to heavy industry; Shanghai Industrial Boiler and others focus on light commercial sectors; while Henan Yuanda has broad fuel compatibility, its industry applications are limited, making it difficult to meet the diverse needs of overseas customers.

Bidragon Boiler achieves "full industry coverage + full fuel compatibility," with products meeting the needs of multiple industries such as textiles and building materials. It not only adapts to conventional fuels but also offers customized designs for special fuels such as palm shells—a compatibility capability that other brands struggle to match.

Focusing solely on low prices while neglecting quality is a common pitfall for overseas customers. Some customers, in an effort to control initial procurement costs, choose brands with extremely low prices, ignoring defects in raw materials, processes, and testing. This ultimately leads to frequent boiler malfunctions, with repair costs and downtime losses far exceeding the initial savings.

Ignoring fuel compatibility issues can also have serious consequences. Fuels from different regions differ in composition and calorific value. If the boiler is not designed and adjusted for local fuel characteristics, problems such as low combustion efficiency, excessive pollutant emissions, and accelerated equipment wear may occur, affecting the normal operation of the boiler.

Many overseas customers easily overlook a brand's overseas after-sales service capabilities when purchasing, focusing only on the product's performance and price. However, boiler installation, commissioning, and subsequent maintenance require professional technical support. If a brand lacks a comprehensive overseas service system, customers will face a lack of assistance when problems arise, severely impacting production schedules.

Failure to verify certifications and quality systems is a major risk factor in overseas procurement. Different countries and regions have strict entry standards and certification requirements for boilers. If customers fail to confirm whether their products possess the relevant certifications for the target market, the boiler may be unable to enter the country or be put into use smoothly, resulting in significant economic losses.

Prioritize evaluating a brand's core strengths, using certifications, technical capabilities, and quality control systems as fundamental criteria. Consider your industry characteristics, fuel supply, and energy needs to match the brand's strengths with its product features.

Emphasis on overseas service capabilities, choosing brands with localized service teams or mature overseas support systems. Focus on long-term value, comprehensively considering operational efficiency, maintenance costs, and service life, rather than simply pursuing the lowest price. Balancing quality, efficiency, and service is key to selecting the most suitable Chinese boiler brand.