The steam generator is used for printing and dyeing, and it is also a chemical processing process. After the chemical treatment of the fiber material, it needs to be washed and dried repeatedly. The steam heat energy consumption is large, and harmful substances are polluted to pollute the air and water. In the printing and dyeing process, if you want to improve steam utilization and reduce pollution, you need to buy heat resource through buying steam.

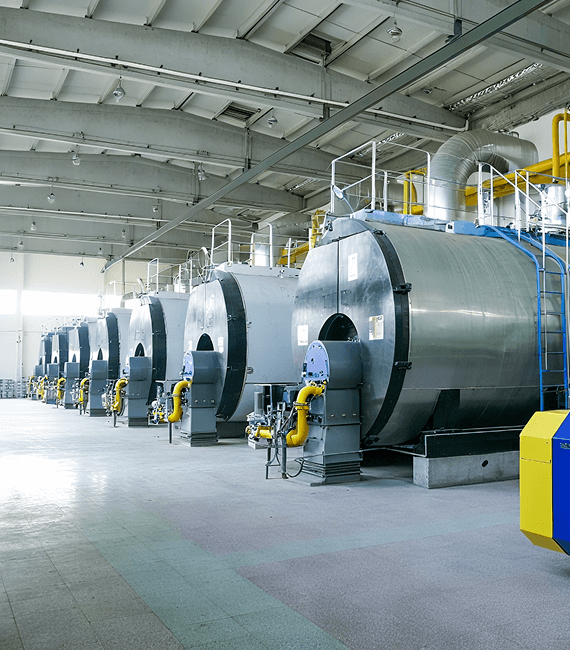

However, the problem is that almost all of these equipments cannot directly use the high-pressure steam that has just entered into the factory. The steam purchased at high pressure needs to be reduced, which results that the steam is not enough for the machines. In this way, the high temperature and high pressure steam can not be directly contradicted with the input of the equipment steam, which inevitably causes steam waste. However, if a steam generator is used to generate steam, the pressure controller can adjust the steam pressure accordin to actual production conditions. At the same time, the steam generator is fully automated with one-button operation, reducing labor costs.