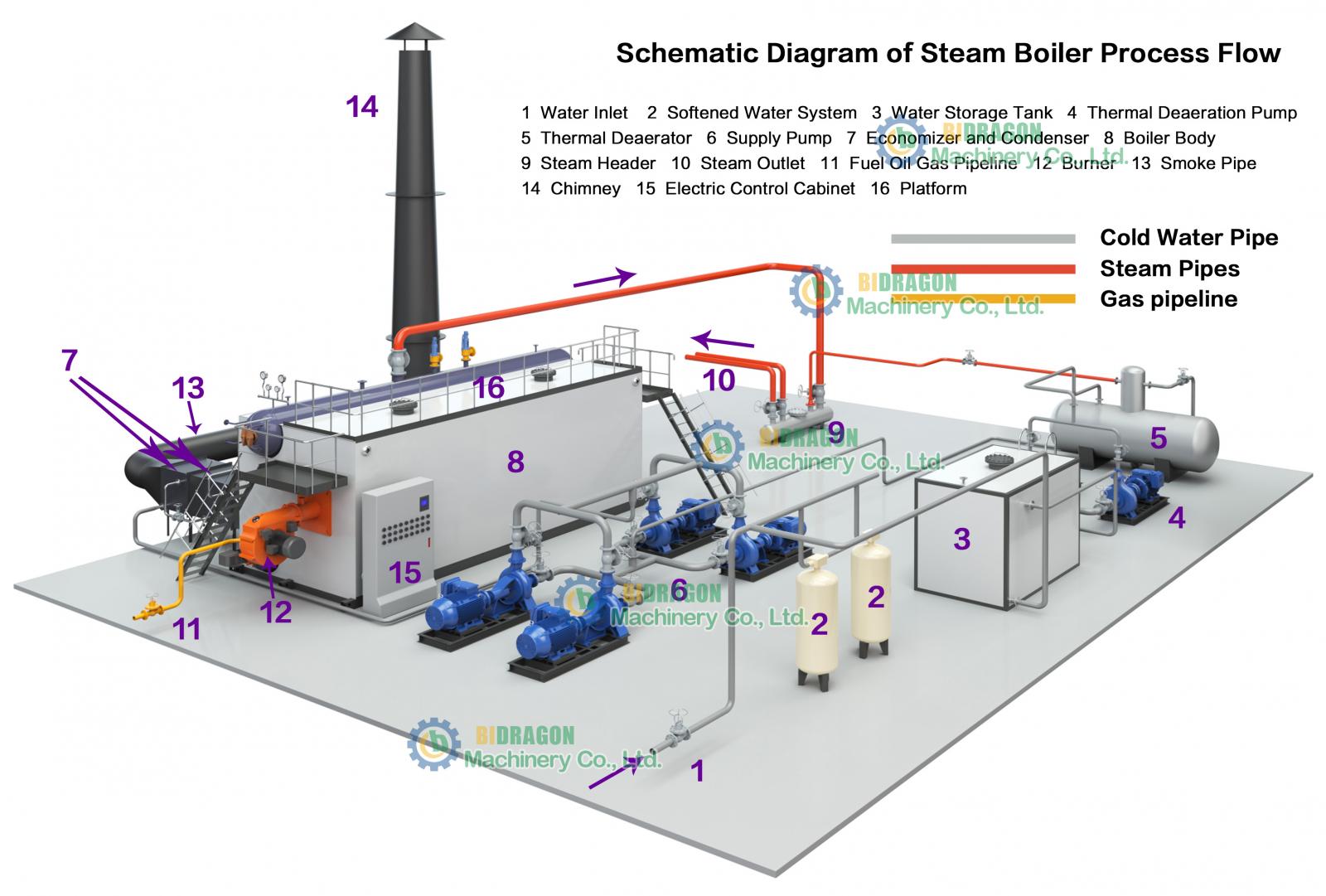

Boiler Feed Water Deoxygenation Technology

In the process of boiler feedwater treatment, deoxygenation is a very critical link. Oxygen is the main corrosive substance in the boiler water supply system. The oxygen in the water supply system should be quickly removed, otherwise it will corrode the boiler water supply system and components. The corrosive substance iron oxide will enter the boiler, deposit or adhere to the boiler tube wall and On the heating surface, insoluble and poor heat transfer iron scale is formed. The corroded iron scale will cause pits on the inner wall of the pipe and increase the resistance coefficient. When pipeline corrosion is severe, pipeline explosion accidents may even occur. The state stipulates that steam boilers with an evaporation capacity greater than or equal to 2 tons per hour and hot water boilers with a water temperature greater than or equal to 95°C must be deoxygenated.

For steam boilers, when the rated evaporation capacity is ≥6t/h, oxygen should be removed. For boilers with rated evaporation capacity <6t/h, deaeration measures should be taken to ensure that the oxygen content of the boiler water supply is ≤0.05mg/L when local corrosion occurs; For hot water boilers, when the rated power ≥ 4.2MW should be deoxygenated, and the rated power <4.2WM should be deaerated as much as possible.

Failure to carry out reasonable deaeration will cause corrosion to boiler feed water pipes, economizers and other ancillary equipment, causing economic losses that will be dozens or hundreds of times the cost of deaerators.