A water level gauge:

The water level gauge should correctly and clearly display the actual water level in the boiler; the water level gauge should be cleaned regularly according to the clarity of the glass plate of the water level gauge: when cleaning, first manually feed the water to make the boiler reach the highest water level; the second step is to turn the water pump switch back Automatic water supply; thirdly, close the valve near the boiler at the bottom of the water level gauge; fourthly, open the drain valve outside the tee; fifthly, close the drain valve outside the tee; sixth, open the valve inside the tee near the boiler. The above six steps are indispensable. If one rinse is not clean, it can be repeated until the rinse is clear. Remember: the valve in the tee near the boiler is a normally open valve, and it must be in the normally open position during the operation of the boiler. After flushing the water level gauge, the valve must be opened immediately, otherwise the boiler will have a water shortage accident.

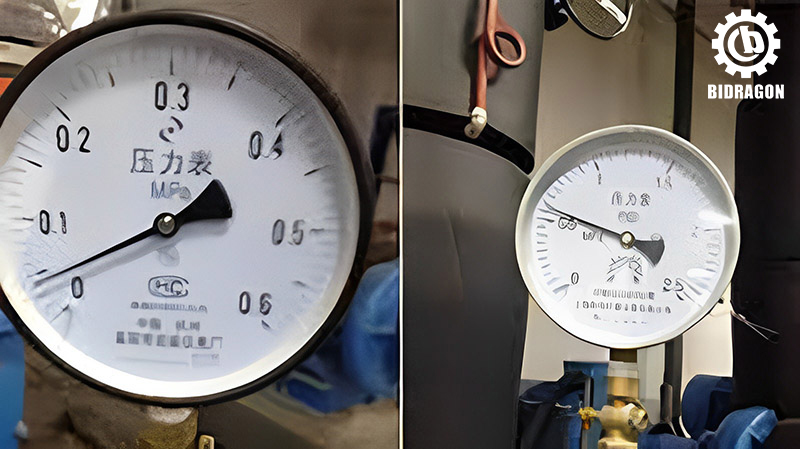

B pressure gauge

The pressure gauge is an instrument that truly represents the working pressure in the boiler, and its accuracy should be guaranteed at all times; if it is damaged, it should be replaced immediately; when replacing, rotate the three-way cock 90° to prevent the steam in the boiler from leaking, and should pass the three-way cock regularly. Flush the gauge elbow.

C electrode

The electrode is the component that provides the water level signal to the electric control box. The electrode should be cleaned regularly according to the furnace water condition; when the cleaning should be in the state of shutdown and there is no pressure in the furnace, an automatic chain protection test should be carried out after cleaning to check the automatic water supply.

First, automatic chain protection inspection

a) Turn on the burner switch and turn on the automatic water supply switch;

b) Turn on the main power switch, there is no water in the furnace at this time, the alarm alarm, the working light of the water pump is on, and the working light of the burner is not on, it is normal; if it is not normal, the test should be stopped, and the longest electrode should be cleaned or replaced.

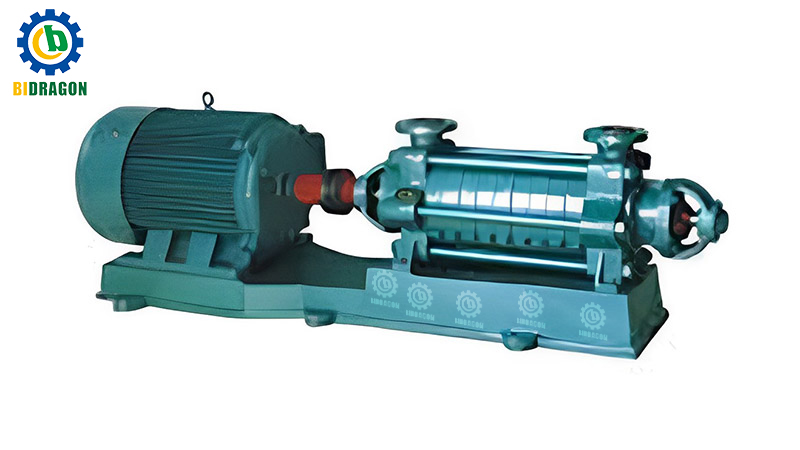

Second, automatic water supply inspection: After the boiler's automatic chain protection inspection is normal, the automatic water supply inspection is carried out.

a) The working switch of the water pump is in the automatic state;

b) When the water level reaches the highest safe water level, the working light of the pump goes out;

c) When the water level reaches the bottom safe water level, the working light of the pump is on;

d) The items b and c are normal as mentioned above; on the contrary, if they are abnormal, the two shorter electrodes should be cleaned and replaced;

e) Third, the electrode should be cleaned at least once a month and replaced once every 12 months.

D pressure protection

The boiler is equipped with a pressure switch (pressure controller). The pressure switch sets two pressure values for turning off the burner when the pressure reaches the set maximum working pressure; and turning on the burner when the pressure reaches the set minimum working pressure. The working condition of the pressure switch should be inspected frequently. The inspection method is as follows:

First, close the air outlet valve, the pressure in the boiler rises, when the set maximum working pressure (read by the pressure gauge) is reached, the burner working light is off, it is normal; otherwise, it is abnormal, and the pressure switch should be replaced immediately. The method is the same as the pressure gauge, until it is normal.

Second, fully open the main steam valve, the pressure in the boiler drops, when it drops to the set minimum working pressure (reading through the pressure gauge), the burner working light is normal; otherwise, it is abnormal, and the pressure should be replaced immediately at this time. switch until normal.