1. Installation of steel frame and platform

The main contents of this stage are: check the number and dimensions of the steel frame platform, fill in the records, adjust and correct the exceeding standard, and fill in the corrected actual size in the record sheet; configure the basic horn; assemble the bulk steel frame into After the inspection is qualified, it is hoisted into place, aligned, fixed, welded steel beams, the geometric dimensions after welding are measured, and the steel frame installation record is filled; the boiler foundation is grouted for the second time; the steel platform bracket is installed.

2. Installation of the heating surface of the boiler body

The main contents of this stage are: the quality review of the drum and the header, especially the quality of the account nozzle should focus on inspection, measurement, and fill in the records; Proofing, annealing and pipe end treatment; installation and fixing of drum supports and drums, and making records; hoisting of headers, aligning and fixing in place, and making records; pipe expansion, strictly control the quality of expansion pipes , and make a record; before and after the expansion of the pipe, each pipe should be subjected to a ball pass test, and records should be made, etc.

3. Installation of economizer

The main work content at this stage is: the installation of the steel tube economizer is very similar to that of the superheater; the installation of the finned economizer should mainly pay attention to the parallelism of the flange surface of the finned tube end and the gaskets should be coated with graphite powder and water. Pressure test and make economizer installation records and hydraulic test records.

4. Installation of the internal device of the drum

The installation of the internal devices of the drum is carried out after the boiler body has passed the water pressure test. The main contents of the work are: Count the number of internal devices, weld them firmly one by one, prevent the occurrence of steam-water channels, ensure the separation effect of steam and water, and reserve expansion according to the figure. gap. Fill in the ball pass record and the drum seal record of the downward tube in the drum.

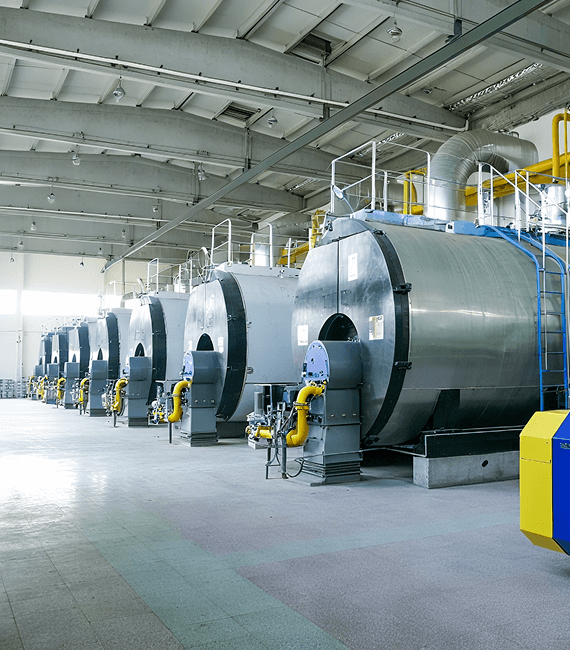

5. Installation of boiler combustion device

The combustion devices of industrial boilers come in various forms. Now take the installation of the chain grate as an example. The work content of this stage is: check all components before the assembly of the chain grate, especially the pitch and thickness of the chain and the chain plate. The inspection of the furnace frame should be recorded; the assembly deviation of the front and rear shafts and sprockets of the furnace frame should be inspected and recorded; the installation of the lower guide rail and the wall plate seat should be based on the center line of the boiler, and the position of the wall plate and beam should be aligned, leaving an expansion gap. ; Installation of brackets and side seals; Installation of front and rear shafts; Installation of furnace chains; Installation of grate bars;

6. Installation of steam and water pipes, valves and thermal instruments within the scope of the boiler

This part of the work is relatively detailed, and it is necessary to make inspection, test, and installation records one by one.

7. Water pressure test of the pot body

There must be representatives of the construction unit and supervision engineers to participate, and visas should be issued on the overall hydraulic test report.

8. Make a record of the furnace construction and thermal insulation construction and the tightness test of the air duct and flue.

9. For the installation of auxiliary equipment, in addition to making installation records, a single-machine trial operation should be carried out and qualified.

10. Oven, cooker. It is necessary to make the baking and boiling plan, formulate the heating curve, and control it to ensure the effect.

The selection of industrial gas boilers is very important. Reasonable selection can ensure the smooth progress of production, reduce equipment investment costs and operating costs, and ensure the interests of users.