In industrial boiler systems, boilers are core equipment, and their efficient and stable operation depends on the coordination of various components. The combustion system provides heat energy for the boiler, the pipeline system is responsible for the transportation and distribution of steam, and the water treatment system ensures the quality of boiler water. Among them, the boiler feed water tank is often regarded as an auxiliary equipment, but it plays an indispensable role in the entire system.

The boiler feed water tank is a key container for storing, preheating boiler feed water, and performing preliminary chemical treatment. It can collect and balance the feed water and condensate in the system to ensure that the boiler continues to have a stable water supply. At the same time, the feed water tank effectively improves the operating efficiency of the boiler and extends the service life of the boiler by preheating and chemically treating the feed water.

A properly designed and integrated feed water tank system, especially when combined with condensate recovery and deaeration, can contribute to an overall thermal efficiency improvement of up to 1–3%, and help reduce equipment failure by improving water quality and temperature stability.

The boiler feed water tank is a container with three functions: water collection, preheating and chemical treatment. It not only bears the basic function of storing feed water, but also preheats the feed water through the internal heating device to reduce the heat load of the boiler; at the same time, it treats the dissolved oxygen and other impurities in the water by adding chemical agents to prevent corrosion and scaling inside the boiler.

Compared with a standard feed water tank, the deaerator is specifically designed for highly efficient oxygen removal, while the feed water tank mainly focuses on storage, preheating, and basic chemical mixing. The two components serve complementary but distinct roles in the boiler system. In practical applications, the deaerator is often used in conjunction with the feed water tank. The deaerator transports the treated water to the feed water tank, and then the feed water tank supplies water to the boiler.

In the system, the boiler feed water tank is closely related to cold water supply, condensate recovery and flash steam. Cold water supply enters the system through the feed water tank to make up for the water loss caused by steam consumption and sewage discharge; condensate recovery reintroduces the condensed water into the feed water tank to realize the recycling of water resources; flash steam can be used to heat the water in the feed water tank, increase the feed water temperature, and further improve the energy efficiency of the system.

Controlling dissolved oxygen is one of the important functions of the boiler feed water tank. Dissolved oxygen in water will react with the metal surface of the boiler to cause corrosion and shorten the service life of the boiler. By adding chemical agents such as sodium sulfite to the feed water tank, it can react chemically with the dissolved oxygen in the water and remove it. A properly designed feed water tank can optimize the mixing effect of the agent, reduce the amount of agent used, and reduce the treatment cost. At the same time, effective control of dissolved oxygen can also reduce the frequency of boiler purge and reduce the waste of water resources and energy.

Thermal shock refers to the stress and fatigue damage caused by rapid and uneven temperature changes in boiler components, especially when cold feed water enters a hot boiler drum or tubes, creating localized thermal gradients and stress concentrations. High-temperature feed water can effectively reduce the temperature difference between feed water and boiler water, reduce the generation of thermal stress, and protect the heating surface of the boiler. By preheating the feed water in the feed water tank to make the feed water temperature close to the boiler water temperature, the service life of the boiler can be significantly extended and the cost of equipment maintenance and replacement can be reduced.

There is a direct relationship between feed water temperature and boiler thermal efficiency. Higher feed water temperature means that the boiler needs to consume less energy to heat the water to boiling point, thereby improving thermal efficiency. When the load fluctuates, a stable feed water temperature can ensure the stability of the boiler capacity and avoid the occurrence of unstable steam output due to changes in feed water temperature. This is particularly important for industrial production processes that require a continuous and stable steam supply.

Optimizing the design of the feed water tank can effectively reduce the amount of chemical agents added. For example, by properly designing the stirring device of the feed water tank, the chemical agent can be fully mixed with water, improving the treatment effect and reducing the waste of agents. In addition, by temperature management, increasing the feed water temperature can reduce the heat loss caused by low-temperature feed water, while reducing the boiler's sewage discharge, reducing the waste of water resources and water treatment costs.

In terms of material selection, different materials have their own advantages and disadvantages. Carbon steel has low cost and good mechanical properties, but it is easy to rust and needs anti-corrosion treatment; stainless steel has strong corrosion resistance, but high cost; cast iron has good wear resistance and corrosion resistance, but it is heavy and difficult to process; Plastic materials are generally not recommended for boiler feed water tanks in industrial applications due to poor temperature and pressure resistance. They may only be suitable for non-heated storage in auxiliary low-temperature processes.

The storage capacity design should follow certain principles, usually to meet the water storage capacity of one hour evaporation. This can not only ensure that the boiler has sufficient water supply in an emergency, but also avoid the increase in floor space and cost caused by too large a water tank.

In the thermal pretreatment system, the configuration of the steam ejector is crucial. Steam ejectors can spray steam into water evenly, achieve efficient heating and mixing, and increase the feed water temperature.

Insulation design and energy efficiency optimization are also key links in feed water tank design. Good insulation measures can reduce heat loss and improve energy efficiency. Insulation materials such as rock wool and polyurethane are usually used to wrap the feed water tank to reduce heat dissipation.

If the preheating system of the feed water tank is insufficiently configured, resulting in too low a feed water temperature, the boiler will produce greater thermal stress and cause thermal shock. For example, a factory had insufficient power of the steam ejector in the feed water tank, and the feed water temperature could not meet the design requirements. After half a year of operation, multiple cracks appeared on the heating surface of the boiler, and the repair cost was as high as hundreds of thousands of yuan. To avoid such problems, the preheating system should be reasonably configured according to the actual needs of the boiler to ensure that the feed water temperature meets the requirements.

Unreasonable cold water inlet point and water replenishment method will lead to uneven water temperature in the water tank, and local low temperature areas are prone to corrosion. For example, injecting cold water directly into the tank without proper mixing can cause thermal stratification, leading to localized temperature differences that promote condensation and corrosion at the colder areas, typically near the tank bottom. The correct way to replenish water is to introduce cold water into the hot water area of the water tank, and through reasonable water flow design, the cold water and hot water are fully mixed to maintain a uniform water temperature.

Wrong chemical agent dosing point will cause the agent to fail to fully play its role, affecting the deoxygenation and water quality treatment effect. If the agent is added to an area with too fast water flow, the agent will be taken away before it can fully mix with the water, and the dissolved oxygen cannot be effectively removed. The agent should be added in an area with relatively slow water flow and good mixing effect to ensure that the agent is fully in contact with the water.

Wrong design and position of water supply pump will affect the stability and efficiency of water supply. For example, if the position of the water supply pump is too high, it will lead to excessive suction, easy to cause cavitation and damage the water pump; improper selection of water supply pump flow and head will lead to insufficient water supply or energy waste. The feed pump should be reasonably designed and installed according to the actual needs of the boiler to ensure its stable operation.

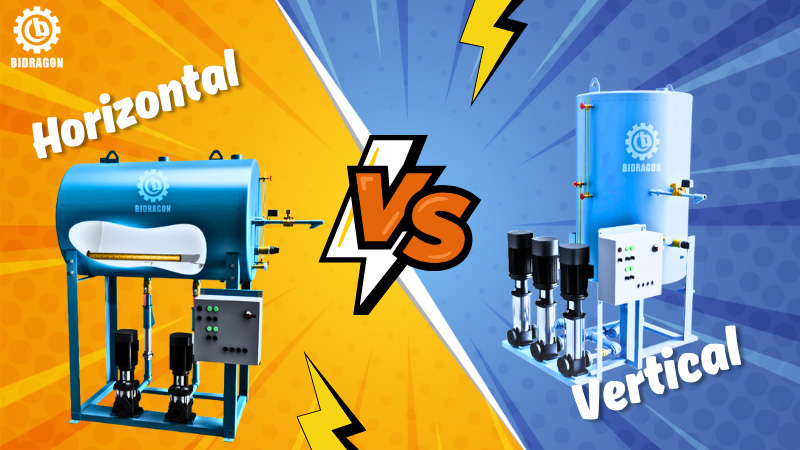

There are obvious differences between horizontal and vertical feed tanks in terms of installation space, pump selection, and capacity. Horizontal feed tanks occupy a larger area but are lower in height, and are suitable for places with more spacious space and height restrictions; vertical feed tanks occupy a smaller area and are higher in height, and are suitable for places with tight space. Pump selection is primarily based on system head requirements and piping configuration, rather than the tank’ s horizontal or vertical orientation. However, vertical tanks may require consideration of greater static head differences due to their height. In terms of applicable scenarios, small and medium-sized boilers can use vertical feed tanks to save space due to their relatively small water consumption; large industrial boiler rooms have a large water consumption, and horizontal feed tanks can better meet their water storage and supply needs.

In terms of standard functions and optional configurations, both types of feed tanks are usually equipped with basic functions such as pump circulation, thermometers, and instruments. In addition, optional configurations such as deaerator interface and automatic control system can be selected according to actual needs to improve the automation and operation efficiency of the system.

Daily inspections should focus on the temperature, pressure, overflow and other parameters of the feed tank. Regularly check whether the temperature is within the normal range, whether the pressure is stable, and whether the overflow port is unobstructed, so as to promptly discover and deal with potential problems.

Monitoring the addition of chemical agents and the supply of cold water is also crucial. By installing flow meters and concentration monitors, the amount of chemical agents added and the amount of cold water supplied can be grasped in real time to ensure the water treatment effect and stable operation of the system.

Annual maintenance focuses include coating inspection, anti-corrosion, and anti-scaling. Check whether the coating inside the water tank is damaged and repair it in time; perform anti-corrosion treatment on the water tank to prevent metal corrosion; clean the scale and impurities inside the water tank to ensure the normal use of the water tank.

A properly designed and maintained boiler feed tank is the key to ensuring the safe, efficient and low-cost operation of the boiler system. It can not only effectively reduce equipment corrosion and damage, improve thermal efficiency, but also reduce water treatment costs and energy consumption. Enterprises should fully consider the selection and configuration of the feed water tank in the early stage of boiler system design to ensure its compatibility and matching with the boiler and the entire system. At the same time, strengthen daily maintenance and monitoring, discover and solve problems in a timely manner, so as to achieve long-term stable operation of the boiler system and create greater economic benefits for the enterprise.