In the complex landscape of industrial operations, High Pressure steam boilers stand as indispensable workhorses, serving as the core energy source that drives a wide range of critical processes. A High Pressure steam boiler is a specialized industrial equipment designed to heat water to generate steam at pressures significantly higher than atmospheric pressure, delivering a concentrated and powerful form of thermal energy.

Its role is particularly pivotal in industries where precise, high-temperature steam is non-negotiable. For instance, in power generation, it supplies the high-energy steam required to drive turbines and produce electricity; in food processing, it ensures thorough sterilization and consistent heating to maintain product safety and quality; in the chemical industry, it enables controlled reactions and efficient distillation; and in the textile sector, it facilitates uniform dyeing and drying processes.

When defining "high pressure" in the context of steam boilers, the threshold typically starts above 15 pounds per square inch (PSI), which is the point where steam begins to exhibit enhanced thermal properties beyond low-pressure counterparts. However, modern industrial High Pressure steam boilers operate at far higher pressures, often ranging from several hundred to over a thousand PSI, depending on specific industrial requirements.

A fundamental relationship exists between pressure and steam temperature: as pressure increases, the temperature at which water boils (and thus the temperature of the resulting steam) rises proportionally, along with the steam’s energy content. This means High Pressure steam carries more thermal energy per unit volume, making it a far more efficient medium for transferring heat and powering industrial processes.

Industries rely on High Pressure steam for multiple critical reasons. Faster heating is a key advantage, as the high-temperature steam reduces heat transfer time, accelerating production cycles. In applications like sterilization, the high temperature of High Pressure steam ensures the complete elimination of microorganisms, a necessity in food and pharmaceutical industries. For power generation, the high energy content of the steam enables it to drive large turbines with greater efficiency, maximizing electricity output. Additionally, in large-scale production, High Pressure steam supports consistent and uniform processing, enhancing overall operational efficiency and product quality.

Given the extreme conditions they operate under, High Pressure steam boilers are subject to strict safety requirements and system design standards. These standards cover aspects such as material strength, pressure vessel integrity, safety valve specifications, and monitoring systems, all aimed at preventing accidents and ensuring reliable operation. Compliance with international and local standards is non-negotiable to safeguard personnel, equipment, and the surrounding environment.

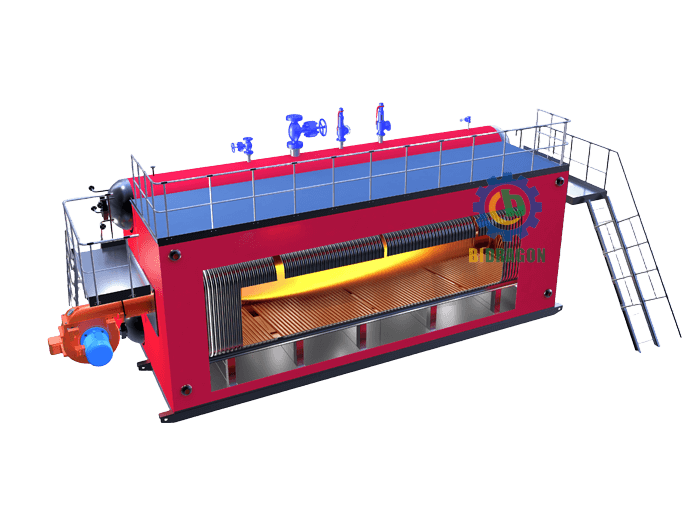

The operation of a High Pressure steam boiler follows a straightforward yet precise sequence, centered on converting water into high-energy steam through controlled heating. The basic working principle unfolds in four key steps: first, water (known as feedwater) is supplied to the boiler’s water chamber via a feedwater system; second, the feedwater is heated in a furnace using a fuel source (e.g., gas, coal, or biomass); third, as the water absorbs heat, it reaches its boiling point and vaporizes into steam, which is then compressed to achieve the desired high pressure; finally, the High Pressure steam is routed to industrial processes (such as heating or sterilization) or to turbines for power generation.

To execute this process reliably, High Pressure steam boilers rely on several core components, each with a critical function:

Combustion Chamber: Where fuel is burned to produce hot gases, which transfer heat to the water.

Heat Exchanger: A network of tubes or surfaces that facilitate efficient heat transfer from the hot combustion gases to the feedwater, ensuring maximum energy absorption.

Feedwater System: Includes pumps, valves, and filters that deliver clean, preheated water to the boiler, preventing scale buildup and maintaining consistent water levels.

Superheater: An optional but common component that further heats the steam to temperatures above its saturation point, increasing its energy content and reducing moisture (critical for turbine efficiency).

Control System: A digital or automated interface that monitors and regulates pressure, temperature, water level, and fuel flow, ensuring stable operation and safety.

Industrial High Pressure boilers typically operate within a specific range of pressures and temperatures to meet industry needs: pressures often range from 150 PSI to 3,000 PSI, while temperatures can vary from 350°F (177°C) to over 1,000°F (538°C), depending on the application. Modern designs also prioritize continuous operation, with features like automated fuel feeding, self-cleaning heat exchangers, and remote monitoring capabilities that minimize downtime and reduce the need for manual intervention.

High Pressure steam boilers are categorized into three main types, each with distinct designs, capabilities, and applications:

Fire tube boilers feature a simple design where hot combustion gases pass through tubes that are submerged in a tank of water. The heat from the gases transfers through the tube walls to the water, heating it to generate steam. This design is relatively easy to manufacture, install, and maintain, making it suitable for moderate steam capacities (typically up to around 25,000 pounds per hour) and pressures (usually up to 300 PSI). Fire-tube boilers are often used in small to medium-sized industrial facilities, such as local manufacturing plants or commercial heating systems, where steam demand is not excessively high.

In contrast, water tube boilers have a more complex design where water flows through tubes, and hot combustion gases surround these tubes to heat the water. This configuration allows for better heat transfer efficiency and enables the boiler to handle much higher pressures (often exceeding 1,000 PSI) and temperatures, as well as larger steam capacities (reaching hundreds of thousands of pounds per hour). Water-tube boilers are the preferred choice for heavy industries and power plants, where large volumes of High Pressure, high-temperature steam are required to drive turbines or support intensive manufacturing processes. While they offer superior performance for high-demand applications, they typically require more complex installation and maintenance compared to fire-tube boilers.

Once through boilers (also known as forced-circulation boilers) operate on a unique principle: feedwater is pumped through a series of tubes in a single pass, with no recirculation of water. As the water flows through the tubes, it is rapidly heated, vaporized, and superheated to generate High Pressure steam—all in one continuous process. This design eliminates the need for a large water drum, resulting in a compact, lightweight boiler that can start up quickly and respond rapidly to changes in steam demand. Once-through boilers are highly efficient, with minimal heat loss due to their compact size, and are suitable for applications where space is limited or where fast steam generation is critical, such as in some chemical plants or marine systems. However, they require precise control of water flow and quality to prevent tube damage, and their maintenance can be more specialized.

When comparing these types, fire-tube boilers excel in simplicity and lower upfront costs but are limited in pressure and capacity. Water-tube boilers offer high performance and scalability but come with higher installation and maintenance expenses. Once-through boilers provide compactness and rapid response but demand strict operational control and specialized care. The choice between them depends on the specific needs of the industry, including steam capacity, pressure requirements, space availability, and maintenance capabilities.

High Pressure boilers are defined by a set of key characteristics that make them suitable for demanding industrial applications:

High steam output and efficiency: Designed to generate large volumes of steam per unit time, High Pressure boilers maximize productivity in industrial processes. Their efficient heat transfer systems (such as optimized heat exchangers and superheaters) ensure that a high percentage of the fuel’s energy is converted into usable steam, minimizing energy waste and reducing operational costs.

Robust construction and materials: To withstand the extreme temperatures and pressures they operate under, High Pressure boilers are built using high-strength materials such as carbon steel, alloy steel, or stainless steel. The boiler’s pressure vessels, tubes, and other components are engineered with thick walls and reinforced joints to maintain structural integrity, preventing leaks or catastrophic failures even under prolonged high-stress conditions.

Sophisticated safety and control systems: Safety is paramount in High Pressure boiler operation, so these systems are equipped with advanced safety features. These include pressure relief valves (to release excess pressure), water level sensors (to prevent dry firing, which can damage the boiler), temperature monitors, and flame failure detectors. The control systems, often automated, continuously adjust parameters like fuel flow, air supply, and water feed to keep the boiler operating within safe limits, and they can trigger alarms or shutdowns in case of abnormalities.

Continuous operation capability: High Pressure boilers are designed for 24/7 continuous operation, a necessity for industries with non-stop production cycles (such as power plants, chemical refineries, and large manufacturing facilities). Their durable components, efficient cooling systems, and automated maintenance features (like automatic blowdown to remove sediment) ensure that they can run reliably for extended periods without frequent shutdowns.

Low heat loss and higher energy utilization: The design of High Pressure boilers minimizes heat loss through features such as insulated walls, sealed combustion chambers, and heat recovery systems (like economizers, which preheat feedwater using waste heat from flue gases). This reduces the amount of energy wasted as heat, increasing overall energy utilization and lowering the boiler’s carbon footprint.

Optional features for enhanced performance: Many High Pressure boilers offer optional components to tailor their performance to specific needs. Superheaters, as mentioned earlier, increase steam temperature to improve energy content and process efficiency. Economizers further boost efficiency by recovering waste heat. Automatic blowdown systems remove mineral deposits and impurities from the boiler water, preventing scaling and maintaining heat transfer efficiency, which extends the boiler’s lifespan and reduces maintenance costs.

High Pressure boilers can utilize a wide range of fuels and heat sources, allowing industries to choose the option that best aligns with cost, availability, environmental regulations, and operational needs. The main options include:

Coal: A traditional and cost-effective fuel source, especially for large-scale industrial boilers. Anthracite coal, in particular, is preferred for its high carbon content, which ensures higher combustion efficiency and lower smoke emissions compared to other coal types. While coal is economical, it requires storage space and handling equipment, and its combustion produces higher levels of greenhouse gases and particulate matter, making it less suitable in regions with strict environmental regulations.

Biomass: A renewable and eco-friendly fuel option, biomass includes materials such as wood chips, pellets, agricultural waste (e.g., straw, corn stover), and dedicated energy crops. Biomass is carbon-neutral (since the carbon released during combustion is absorbed by plants during growth), making it a sustainable choice for reducing carbon footprints. It is also widely available in agricultural regions, though its energy density is lower than fossil fuels, requiring larger storage and feeding systems.

Rice Husk: A specific type of biomass derived from rice processing, rice husk is a sustainable fuel with several advantages. It is a waste product, so it is often low-cost or even free in rice-producing areas. It has a relatively high silica content, which can help reduce corrosion in the boiler. Additionally, rice husk combustion produces minimal sulfur emissions, and the ash can be repurposed as a soil amendment or in construction materials. It is well-suited for small to medium-sized boilers in rice-processing facilities or rural industrial areas.

Wood Chips: Another renewable biomass option, wood chips are sourced from forestry residues, sawmills, or dedicated tree plantations. They are compatible with multi-fuel boiler designs, making them a flexible choice. Wood chips have a moderate energy density and produce lower emissions than coal, though their availability may be limited in non-forested regions.

Gas (Natural Gas or LPG): Natural gas and liquefied petroleum gas (LPG) are clean-burning fuels that offer high combustion efficiency and low emissions (producing primarily carbon dioxide and water vapor). They are convenient to use, as they can be delivered via pipelines (for natural gas) or stored in tanks (for LPG), requiring minimal handling. Gas-fired boilers start up quickly, respond rapidly to load changes, and have lower maintenance requirements compared to solid fuel boilers. However, their cost is subject to fluctuations in global gas prices.

Oil (Diesel, Heavy Fuel Oil): Oil is a reliable backup fuel for High Pressure boilers, especially in areas where gas supply is inconsistent. It has a high energy density, ensuring efficient combustion, and oil-fired boilers can achieve high temperatures and pressures quickly. However, oil is more expensive than coal or biomass, and its combustion produces higher emissions (including sulfur oxides and particulate matter) than gas or biomass. It also requires storage tanks and careful handling to prevent spills.

Electric: Electric High Pressure boilers use electricity to heat water, producing zero local emissions—making them an ideal choice for areas with strict environmental regulations (such as urban industrial zones or pharmaceutical facilities) or where fuel storage space is limited. They have a simple design, with no combustion chamber or flue gas system, resulting in lower maintenance costs and quieter operation. However, their operational cost depends on electricity prices, which can be high in some regions, and they require a stable and high-capacity electrical supply.

A growing trend in the industry is the adoption of multi-fuel or hybrid boilers. These systems are designed to use two or more fuel types (e.g., natural gas and biomass, or oil and electric), providing industries with flexibility. For example, during periods of low gas prices, the boiler can run on natural gas; when gas prices spike or supply is disrupted, it can switch to biomass or oil. This flexibility not only helps manage fuel costs but also reduces reliance on a single fuel source, enhancing operational resilience and enabling compliance with changing environmental regulations.

High Pressure steam boilers offer a range of significant advantages that make them a preferred choice for industrial applications, driving efficiency, productivity, and cost savings:

High thermal efficiency and steam quality: Due to their design (including efficient heat transfer systems and optional superheaters), High Pressure boilers convert a large portion of fuel energy into usable steam, resulting in high thermal efficiency. The steam produced is of high quality—with low moisture content (especially when equipped with superheaters)—ensuring that it transfers heat effectively and does not cause damage to equipment (such as turbine blades in power generation).

Faster process heating and energy transfer: The high temperature and energy content of High Pressure steam enable it to transfer heat to industrial processes much faster than low-pressure steam. This reduces the time required for heating, sterilization, or other thermal processes, accelerating production cycles and increasing overall productivity. For example, in food processing, High Pressure steam can sterilize equipment or products in a fraction of the time needed with low-pressure steam.

Lower operational cost per unit of steam generated: While the upfront cost of a High Pressure boiler may be higher, its high thermal efficiency translates to lower fuel consumption per unit of steam produced. This reduces the operational cost over the boiler’s lifespan, as less fuel is needed to generate the same amount of steam compared to less efficient boilers. Additionally, features like heat recovery systems (economizers) further lower energy waste, contributing to long-term cost savings.

Flexibility in fuel choice: As outlined earlier, High Pressure boilers can run on a wide range of fuels, including coal, biomass, gas, oil, and electricity. This flexibility allows industries to select the most cost-effective and available fuel source in their region, and even switch fuels (with multi-fuel boilers) in response to price changes or supply disruptions. This adaptability helps control costs and ensures operational continuity.

Improved product quality in heat-dependent industries: In industries where heat plays a critical role in product quality—such as food and beverage (sterilization, pasteurization), pharmaceuticals (purification, reaction control), and textiles (dyeing, drying)—High Pressure steam provides precise and uniform heating. This consistency ensures that products meet strict quality standards, reducing defects and improving customer satisfaction. For example, in textile dyeing, uniform high-temperature steam ensures that dyes are absorbed evenly, resulting in consistent coloration.

Better reliability for continuous industrial operations: High Pressure boilers are engineered for durability and continuous operation, with robust components and advanced safety systems that minimize the risk of breakdowns. Their ability to run 24/7 without frequent shutdowns is essential for industries with non-stop production cycles (like power plants or chemical refineries), as it prevents costly production delays and ensures a steady supply of steam for critical processes. Additionally, automated maintenance features (like automatic blowdown) help prolong the boiler’s lifespan and reduce the need for unscheduled maintenance.

High Pressure steam boilers find widespread application across various industries, where their ability to deliver high-temperature, high-energy steam is critical to supporting key processes:

Food & Beverage Industry: In this industry, High Pressure steam is essential for ensuring food safety and product quality. It is used for sterilization (to eliminate harmful bacteria and pathogens in equipment, containers, and food products), pasteurization (to extend the shelf life of products like milk, juice, and sauces by heating them to a specific temperature), and cooking (in large-scale commercial kitchens or food processing plants, where it provides uniform heat for baking, boiling, or steaming food products).

Textile & Garment Industry: High Pressure steam plays a vital role in textile manufacturing and garment production. It is used for dyeing (to ensure that dyes penetrate fabric fibers evenly and set permanently, resulting in vibrant and long-lasting colors), drying (to quickly remove moisture from fabrics after washing or dyeing, reducing production time), and ironing (in garment factories, where High Pressure steam irons deliver powerful heat to remove wrinkles and give garments a smooth, professional finish).

Chemical & Pharmaceutical Industry: High Pressure steam is a cornerstone of operations in this sector, where precision and consistency are critical. It is used for reaction heating (providing the exact temperature required to initiate and sustain chemical reactions, ensuring product yield and purity), distillation (supplying the heat needed to separate components in mixtures based on their boiling points, a key step in producing solvents, fuels, and pharmaceutical ingredients), and purification (sterilizing equipment and processes to meet strict regulatory standards for pharmaceutical products, preventing contamination that could compromise product safety).

Power Generation Industry: This is one of the largest users of High Pressure steam boilers. The high-energy steam generated by the boilers is directed to drive turbines, which are connected to generators that produce electricity. In cogeneration (or combined heat and power, CHP) systems, the steam is also used to provide heating for industrial facilities or nearby communities after passing through the turbine, maximizing energy utilization and reducing waste. High Pressure boilers are essential here for achieving the high efficiency needed to meet large-scale electricity demand.

Paper & Pulp Industry: High Pressure steam supports multiple stages of paper and pulp production. It is used for steam drying (removing moisture from pulp sheets or paper rolls to achieve the desired thickness and texture), as well as in the cooking process (heating wood chips with chemicals to break down lignin and separate cellulose fibers, the primary component of paper). The high temperature of the steam ensures efficient cooking and drying, enabling continuous production of high-quality paper products.

A critical consideration across all these applications is matching the boiler’s type (e.g., fire-tube, water-tube) and capacity (steam output per hour) to the specific production demand. Mismatched equipment—such as a boiler with insufficient capacity for a large-scale textile plant or a High Pressure water-tube boiler for a small food processing facility—can lead to inefficiencies, increased operational costs, or even production bottlenecks, highlighting the importance of careful application-specific selection.

Selecting the right High Pressure boiler is a decision that directly impacts operational efficiency, cost-effectiveness, and long-term reliability. The process requires a systematic evaluation of multiple factors tailored to the industry’s unique needs:

The first step is to define the exact thermal needs of the industrial process. This includes identifying the minimum and maximum temperature required for key operations (e.g., 350°F for food pasteurization vs. 800°F for chemical reactions) and the corresponding steam pressure needed to achieve that temperature. For example, a power plant requiring steam to drive a high-efficiency turbine may need pressures above 2,000 PSI, while a small beverage facility may only need 150–300 PSI. Choosing a boiler that can consistently meet these parameters—without overdesigning (which wastes energy) or underperforming (which disrupts production)—is foundational.

Next, assess the fuel options accessible in the facility’s location, including their cost, availability, and compatibility with the boiler. For instance, a facility in an agricultural region may have easy access to biomass (e.g., rice husk, straw) at low cost, making a biomass-fired boiler ideal. In contrast, an urban pharmaceutical plant with strict air quality regulations may prioritize electric or natural gas boilers, which produce fewer local emissions. It is also critical to comply with local, national, and international emission standards (e.g., limits on sulfur dioxide, nitrogen oxides, or carbon dioxide) to avoid penalties and ensure environmental sustainability. This may involve selecting low-emission fuels or investing in additional pollution control equipment (e.g., scrubbers for coal-fired boilers).

The boiler’s intended operation schedule (e.g., 8-hour shifts vs. 24/7 continuous operation) and maintenance requirements must align with the facility’s capabilities. For facilities running non-stop (e.g., power plants, refineries), a boiler designed for high durability and minimal downtime—such as a water-tube boiler with robust components—is preferable. In contrast, a small manufacturing plant with intermittent use may opt for a fire-tube boiler, which has simpler maintenance needs. Additionally, calculate the total cost of ownership (TCO), not just the upfront purchase price. TCO includes fuel costs (the largest long-term expense), maintenance costs (e.g., parts, labor for inspections), and energy efficiency (a more efficient boiler reduces fuel bills over time). For example, an electric boiler may have a lower upfront cost but higher operational costs if electricity prices are high, while a biomass boiler may have higher upfront costs but lower fuel costs.

Evaluate the physical constraints of the installation site, including space, ventilation, and access to utilities (e.g., water, electricity, fuel lines). A compact once-through boiler may be necessary for facilities with limited floor space, while a water-tube boiler may require additional space for auxiliary equipment (e.g., superheaters, economizers). Additionally, consider the availability of after-sales service from the boiler manufacturer or local distributors. Prompt service—including routine maintenance, emergency repairs, and access to replacement parts—is essential to minimize downtime if the boiler malfunctions. For facilities in remote areas, choosing a manufacturer with a regional service network or readily available parts is critical.

Many industrial processes have unique requirements that standard boilers cannot meet. In such cases, a customized boiler design—tailored to factors like unusual pressure/temperature needs, multi-fuel compatibility, or integration with existing systems (e.g., cogeneration setups)—can deliver better performance. Additionally, local technical support ensures that the boiler is installed correctly, operators are trained properly, and any issues are resolved quickly. This local expertise is particularly valuable for navigating regional regulations, troubleshooting site-specific challenges (e.g., hard water that causes scaling), and optimizing the boiler’s performance for local conditions.

High Pressure steam boilers are irreplaceable in modern industry, providing high-temperature, high-energy steam to boost efficiency, productivity and product quality across sectors. Their advantages like strong thermal efficiency, flexible fuel options and reliable operation cut costs, reduce environmental impact and minimize downtime.

Choosing the right one isn’t just a purchase, but an investment in long-term success. Aligning its type, capacity and fuel with process needs, local rules and budget ensures lasting value. A well-selected High Pressure steam boiler is key to sustainable, efficient industrial power, helping businesses meet current demands and prepare for the future.