A biomass thermal oil boiler is an industrial heating device that uses biomass energy as fuel and heats thermal oil to transfer heat. It utilizes the heat released from the combustion of biomass fuel to raise the thermal oil to a specific temperature, and then, through a circulation system, transports the heat to the heat-using stages of the production process, meeting various industrial heating needs.

Compared to traditional coal-fired and gas-fired thermal oil boilers, the core difference of biomass thermal oil boilers lies in their fuel type and environmental attributes. Traditional boilers rely on fossil fuels, facing the risk of energy depletion and emitting large amounts of pollutants such as sulfur dioxide and nitrogen oxides; while biomass boilers use renewable biomass resources as fuel, achieving carbon recycling during combustion, resulting in far lower pollutant emissions than traditional boilers.

The emergence of biomass energy as a strategic energy choice for industrial users is driven by multiple factors. Under the global trend of energy structure transformation, fossil fuel prices are experiencing increased volatility, while biomass energy is widely available and its prices are stable. Simultaneously, increasingly stringent environmental policies in various countries place heavy pressure on industrial enterprises to reduce emissions. Biomass thermal oil boilers, which meet environmental requirements and help enterprises control energy costs, have naturally become the preferred choice in the industrial heating field.

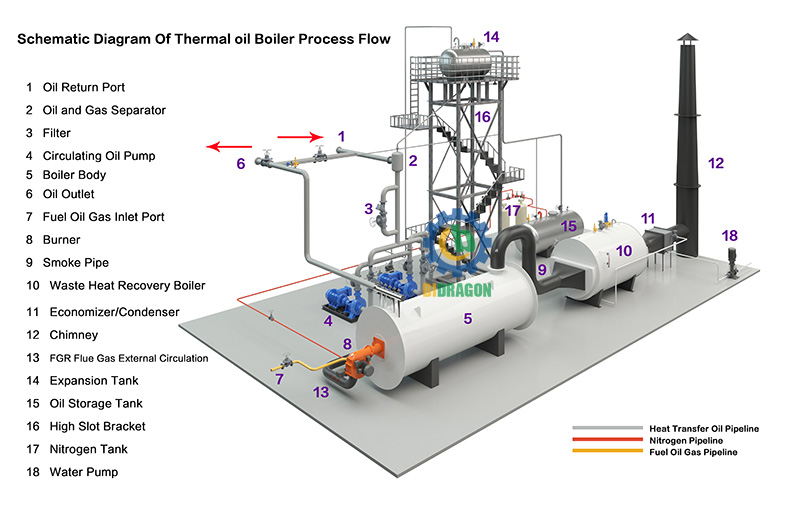

The core working logic of biomass thermal oil boilers revolves around the circulation of thermal oil. In the combustion chamber of the boiler body, biomass fuel is fully combusted to produce high-temperature flue gas. The flue gas transfers heat to the boiler's heating surfaces through radiation and convection. The heating surfaces exchange heat with the internal thermal oil, causing the temperature of the thermal oil to gradually increase.

The heat transfer process uses organic thermal oil as the medium, which has good thermal stability and heat transfer performance. Once the thermal oil is heated to the set temperature, it is driven by a circulation pump into a closed thermal oil circulation system. Flowing through the heat-using equipment, it releases heat to the production process, and after its own temperature decreases, it returns to the boiler for reheating, forming a continuous and stable heat cycle.

A complete biomass thermal oil heating system comprises several key components. Besides the core boiler body (including the combustion chamber and heating surfaces), it includes a biomass fuel supply system, an induced draft and flue gas system, a thermal oil circulation system (circulation pump, expansion tank, and oil storage tank), a temperature control system, and a safety protection system. These components work together to ensure the boiler's efficient, stable, and safe operation.

Biomass thermal oil boilers are highly adaptable to various fuel types. Wood-based fuels are the most widely used, including wood chips, sawdust, and wood pellets. These fuels have high combustion efficiency and low ash content, making them ideal biomass fuels.

Agricultural waste is also an important fuel source, such as rice husks, palm fiber, bagasse, and corn stalks. These wastes, which are normally difficult to process, are recycled and reused as fuel in biomass boilers, reducing environmental pressure and bringing economic benefits to enterprises.

The properties of the fuel directly affect the boiler's combustion efficiency. The calorific value, moisture content, and ash content of fuel are key indicators: the higher the calorific value, the more heat is released per unit mass of fuel; excessive moisture leads to incomplete combustion and reduced thermal efficiency; excessive ash content easily causes ash accumulation on heated surfaces, clogging of flues, increased maintenance costs, and affects boiler performance. Therefore, selecting biomass fuel with suitable properties is fundamental to ensuring efficient boiler operation.

High efficiency, energy saving, and low-cost operation are the outstanding advantages of biomass thermal oil boilers. High-quality biomass boilers can achieve thermal efficiencies of over 85%, far exceeding some traditional coal-fired boilers; simultaneously, biomass fuel prices are much lower than fossil fuels such as diesel and natural gas, and combined with high heat transfer efficiency, this significantly reduces the unit heating cost for enterprises.

Stable temperature control is a key characteristic for its suitability for industrial production. Through a precise control system, biomass thermal oil boilers can stably control the thermal oil temperature within the range of 300-320℃, with minimal temperature fluctuations, meeting the needs of industries such as textiles and chemicals that require high temperature precision, and ensuring the stability of production processes.

The combination of low operating pressure and high heat output enhances the safety and practicality of the equipment. The heat transfer oil can achieve high-temperature heat transfer under normal or low pressure, avoiding the safety risks of high-pressure boilers. Simultaneously, the stable high-temperature output meets the needs of various industrial heating scenarios, improving production efficiency.

Environmental attributes and policy compatibility are its core competitive advantages. CO₂ emissions during biomass fuel combustion are far lower than those of fossil fuels, and emissions of pollutants such as nitrogen oxides and sulfides meet national environmental standards, helping companies easily cope with environmental inspections. Furthermore, some regions have introduced subsidy policies for biomass energy utilization, further reducing investment and operating costs for enterprises.

An efficient combustion system is the core of improving boiler performance. A high-quality combustion system should have sufficient combustion space and a reasonable air distribution method to ensure complete combustion of biomass fuel, reduce fuel waste, and lower pollutant emissions. When purchasing, it is necessary to pay attention to whether the design of the combustion system is suitable for the type of biomass fuel selected.

The degree of automation of the fuel supply system directly affects the ease of operation. An automatic feeding system can achieve continuous and uniform fuel supply, reduce manual operation, lower labor costs, and ensure combustion stability. Although manual feeding systems have lower initial investment, they are suitable for small boilers or scenarios with small fluctuations in heat demand. Automatic feeding systems are more practical in large-scale industrial applications.

A reliable thermal oil circulation pump is crucial for ensuring heat transfer. The performance of the circulation pump directly determines the circulation efficiency of the thermal oil, thus affecting the stability of heat supply. When purchasing, it is necessary to pay attention to whether the flow rate, head, and other parameters of the circulation pump match the heating capacity of the boiler, and to choose a reliable product with a low failure rate.

A multi-pass heat exchange structure can improve heat utilization. A multi-pass heat exchanger design extends the contact time between high-temperature flue gas and the heating surface, fully absorbing heat from the flue gas, reducing heat loss, further improving boiler thermal efficiency, and lowering fuel consumption.

A comprehensive safety device and control system is indispensable. Safety devices should include over-temperature protection, over-pressure protection, liquid level protection, and flameout protection, which can trigger protection mechanisms promptly when equipment malfunctions, preventing accidents. A precise control system can automatically adjust parameters such as temperature and pressure, ensuring stable boiler operation.

Fuel Cost Advantages Lay the Foundation for High Returns.

Fuel cost savings are the core of improving the ROI of biomass thermal oil boilers. In industrial heating, fuel costs account for more than 60% of total operating costs. Biomass fuel, processed from agricultural and forestry waste, is 30%-50% cheaper than diesel and natural gas. A medium-sized textile enterprise, after adopting this system, can save 30,000-50,000 yuan in fuel expenses per month, totaling 360,000-600,000 yuan annually. Biomass fuel prices are less affected by international energy markets, and local supply is stable, allowing companies to lock in long-term costs and mitigate volatility risks. Meanwhile, its boiler thermal efficiency reaches 85%-90%, comparable to traditional boilers, efficiently converting fuel input into heat and further amplifying its cost advantage.

Equipment lifespan directly impacts investment amortization efficiency. Traditional high-pressure boilers require maintaining pressures of several megapascals, leading to rapid wear of core components and a lifespan of only 8-10 years. Biomass thermal oil boilers use thermal oil as the medium, achieving high-temperature heat transfer at low pressure (≤0.3MPa), resulting in lower component stress and significantly reduced wear.

High-quality heat transfer oil can also protect internal metal components, and its lifespan can reach 15-20 years under proper use. A longer service life can significantly reduce the pressure of equipment investment amortization and minimize financial losses and production interruptions caused by equipment replacement.

Traditional coal-fired boilers produce large amounts of pollutants from combustion products, requiring expensive desulfurization and denitrification equipment. Maintenance costs for this equipment account for over 40% of total boiler maintenance costs, and tasks such as cleaning heating surfaces and repairing pipelines are cumbersome, with short maintenance cycles and high costs.

Biomass fuel is clean, with low sulfur and nitrogen content and ash content, eliminating the need for complex environmental protection equipment. Routine maintenance only requires cleaning the feeding system, periodically inspecting and replacing the heat transfer oil (lifespan 3-5 years), and lightly cleaning accumulated ash. Annual maintenance costs are only 1/3 to 1/2 of traditional boilers, saving enterprises significant non-production expenses.

Industries such as textile printing and dyeing and chemicals have extremely high requirements for temperature stability. Traditional boilers often experience temperature fluctuations exceeding ±5℃, easily leading to problems such as product color differences and incomplete reactions, increasing defective products and rework rates.

Biomass boilers, relying on advanced automatic control systems and the stability of heat transfer oil, can control temperature fluctuations within ±1℃. Stable heat supply improves product qualification rates, reduces waste, ensures continuous production, extends equipment operating time, indirectly creates considerable output value, and amplifies investment value.

The payback period is a core profitability indicator. Biomass thermal oil boilers, with their cost savings and improved efficiency, have a payback period of only 1.5-3 years, far shorter than the 5-8 years of traditional boilers. This rapid return on investment allows the equipment to generate net profits for enterprises sooner, significantly optimizing investment returns.

A short payback period reduces investment risk and accelerates capital turnover, which can be used for expanding production, R&D, and other secondary value-added activities. Combined with equipment purchase and operation subsidies in some regions, the payback period for some enterprises can be shortened to 1 year. This "short investment, quick return" approach makes it a superior investment choice for industrial enterprises.

Textile Printing and Finishing Industry: Provides stable high-temperature heat for core processes such as dyeing, setting, and drying. Precise temperature control ensures uniform dye adhesion, improving dyeing quality. Simultaneously, efficient heating accelerates drying, boosting production efficiency.

Food and Beverage Processing: Covers multiple stages including sterilization, cooking, concentration, and drying. Low-temperature stable heating protects food nutrients, meeting food hygiene requirements and serving as crucial support equipment for green production.

Chemical and Pharmaceutical Industry: Precisely controls reactor temperature, providing a stable thermal environment for chemical reactions. Low-pressure operation reduces production safety risks, fully meeting the industry's stringent requirements for temperature stability and safety.

Wood Processing and Plywood Manufacturing: Provides energy for wood drying and hot pressing. Stable heating ensures uniform moisture evaporation from the wood, reducing deformation and improving the bonding strength and overall product quality of plywood. (V) Rubber, Plastics, and Asphalt Processing The high-temperature heating capacity is fully utilized, providing continuous high temperatures for material melting, modification, and molding processes, precisely matching the processing heat requirements of various polymer materials and asphalt.

8.Key Considerations for Investing in Biomass Thermal Oil Boilers

The availability and cost of local biomass fuel are primary considerations. Fuel transportation costs directly impact overall operating costs. Enterprises should prioritize locally produced biomass fuels with stable supply. For example, agricultural areas can prioritize rice husks and straw, while forestry areas are suitable for wood chips and sawdust.

Clearly defining one's own heating load and operating temperature requirements is crucial. Production enterprises of different sizes have significantly different heating capacity requirements. It is necessary to select a boiler of matching specifications based on the maximum heat consumption and required maximum temperature of the production process to avoid situations where the boiler is oversized or insufficiently heated.

Site layout must consider both fuel storage and feeding needs. Biomass fuel is bulky, requiring sufficient storage space. The storage area must be ventilated and moisture-proof to prevent fuel deterioration. Simultaneously, the installation location of the feeding system should facilitate fuel transportation to reduce site modification costs. The quality and replacement cycle of heat transfer oil affect equipment operating efficiency and maintenance costs. High-quality heat transfer oil has good thermal stability and oxidation resistance, with a service life of 3-5 years; inferior heat transfer oil is prone to aging and coking, which not only reduces thermal efficiency but also clogs pipes, increasing maintenance costs. Therefore, it is necessary to select heat transfer oil that meets standards and conduct regular testing.

Strict compliance with local environmental and safety regulations is essential. Environmental emission standards and safety approval procedures vary from region to region. Before purchasing boilers, enterprises should understand local policy requirements, select equipment that meets emission standards, and complete relevant approval procedures to ensure legal and compliant operation.

Regularly testing the performance of heat transfer oil is the core of maintenance. The viscosity, flash point, acid value, and other indicators of the heat transfer oil should be tested regularly. When these indicators exceed the standard range, the heat transfer oil should be replaced promptly to avoid decreased thermal efficiency or equipment damage due to heat transfer oil deterioration.

Regularly clean the ash accumulation on the combustion chamber and heat exchanger surfaces. The combustion of biomass fuel produces a small amount of ash, which, if accumulated over time, can affect the heat transfer efficiency of the heating surfaces. Therefore, it is necessary to regularly open the boiler's maintenance doors and clean the ash buildup in the combustion chamber and on the surface of the heat exchanger to ensure smooth heat transfer.

The inspection of the circulation system is crucial. Regularly check the operating status of components such as the circulation pump, valves, and pipes, looking for leaks, blockages, etc., and promptly replace worn seals and aging pipes to ensure the stability of the thermal oil circulation system.

Maintain equipment efficiency through routine commissioning and calibration. Regularly commission the boiler's control and combustion systems, calibrate the accuracy of temperature, pressure, and other sensors to ensure that all equipment parameters are operating at their optimal state, further improving the boiler's thermal efficiency and operational stability.

Biomass thermal oil boilers, with their core advantages of high efficiency, energy saving, and environmental friendliness, provide industrial enterprises with a cost-effective, safe, and stable heating solution. They not only help enterprises reduce energy costs and cope with environmental pressures but also improve production efficiency through stable heating performance, achieving a win-win situation for both economic and environmental value.

Against the backdrop of energy structure transformation and industrial upgrading, biomass thermal oil boilers have become the mainstream choice in the industrial heating field. For industrial enterprises pursuing sustainable development, investing in biomass thermal oil boilers is an investment in future green production and long-term profitability.