In some specialized industrial sectors, production processes place stringent demands on heat source temperatures, often exceeding 200°C, or even reaching as high as 400 or 500°C. However, the positive correlation between pressure and temperature in traditional boilers makes it difficult for them to reach temperatures exceeding 300°C, making them unable to meet the demands of these specialized scenarios.

In the boiler industry, molten salt boilers and thermal oil boilers are recognized as specialized high-temperature heating equipment for their exceptional high-temperature heating capabilities. However, when choosing a suitable boiler, many business decision-makers face a dilemma: should they choose a molten salt boiler or a thermal oil boiler?

In reality, each type of boiler has its pros and cons. To help businesses make informed decisions, this article will first provide an in-depth analysis of the operating principles and product features of molten salt and thermal oil boilers. Then, through a comprehensive comparison of the two, we will provide a professional reference for industrial enterprises to select the appropriate high-temperature heating boiler, helping them achieve safe, efficient, and economical production and operations.

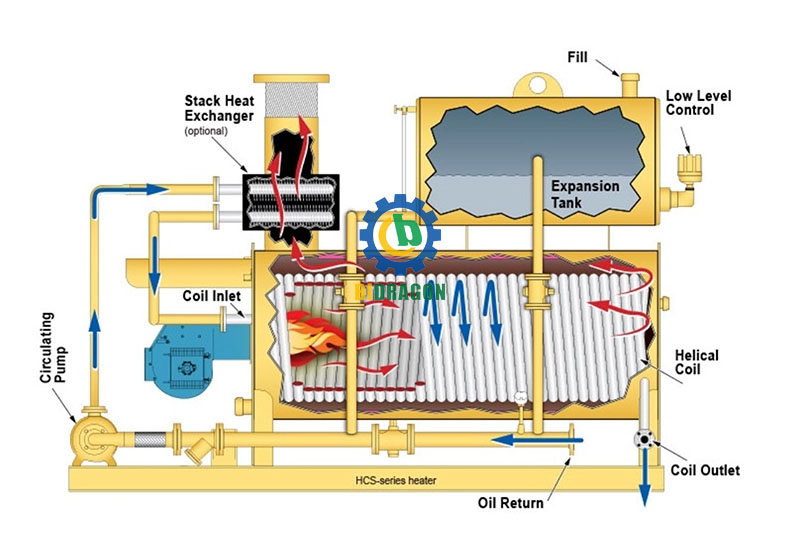

A thermal oil heater, also known as an organic heat transfer medium, is a closed-loop thermal energy device that uses thermal oil as a heat transfer medium. Its operation is as follows: the thermal oil is heated through combustion or electrical heating. A circulating pump then drives the hot oil along pipelines to heat-consuming equipment, releasing heat to meet production process requirements. After heat transfer, the cooled thermal oil returns to the furnace through a return line for reheating. This cycle repeats, continuously providing a stable heat source for industrial production.

The heat transfer medium used in thermal oil boilers is organic thermal oil, which has excellent thermal stability, low vapor pressure, and high specific heat capacity. It is resistant to decomposition and deterioration at high temperatures, maintains stable heat transfer performance over a wide temperature range, and can achieve high temperatures at atmospheric pressure, effectively avoiding the safety risks associated with high-pressure heating.

The typical operating temperature of a thermal oil boiler typically reaches 320°C. With some specialized designs and modifications, such as using high-performance thermal oil and optimizing the boiler's heating structure, operating temperatures can approach 400°C. However, these special operating conditions place even stricter demands on equipment and operational management.

Low-Pressure Operation: Because organic thermal oil has a lower vapor pressure at high temperatures, thermal oil boilers can operate at atmospheric or lower pressures, reducing boiler design and manufacturing complexity and safety risks, and placing relatively low pressure requirements on the equipment.

Precise Temperature Control: Advanced temperature control systems enable precise control of the thermal oil temperature, minimizing fluctuations in outlet oil temperature. This meets the stringent temperature stability requirements of production processes and helps improve product quality consistency.

Medium Medium Safety: While organic thermal oil offers a certain degree of stability, it poses a risk of combustion when exposed to air and open flames during long-term high-temperature operation or system leaks. Furthermore, some thermal oils may generate small amounts of hazardous gases at high temperatures, requiring proper ventilation.

Due to their low pressure and precise temperature control, thermal oil boilers are widely used in various industries, including the following:

Textile Industry: Used in drying and shaping processes during the textile printing and dyeing process, they provide a stable, high-temperature heat source for fabrics, ensuring printing and dyeing quality and physical properties.

Printing and Dyeing Industry: Meet the needs of drying printing inks and heating dyes to ensure color fastness and dyeing results.

Plastics Industry: Provide heat for melting and plasticizing plastic raw materials during processes such as extrusion, injection molding, and blow molding, ensuring smooth production and product quality.

Food Industry: Used in baking, steaming, and sterilization processes in food processing, such as biscuit baking and canned food sterilization. The indirect heating method of thermal oil can prevent food contamination.

Wood Processing Industry: Used in wood drying to remove moisture, prevent deformation and cracking, and improve wood performance and processing quality.

Building Materials Industry: In the production of building materials such as cement, glass, and ceramics, it is used for processes such as preheating and drying raw materials and heating kilns, facilitating the formation and performance improvement of building materials.

A molten salt boiler (or boiler) is a high-temperature thermal energy device that uses a molten salt mixture, such as sodium nitrate and sodium nitrite, as a heat carrier.

Its operation is as follows: Fuel burns in the boiler's combustion system, generating high-temperature flue gas. This flue gas transfers heat to the boiler's heating surfaces through radiation and convection. The heating surfaces transfer heat to the molten salt mixture within, raising the molten salt temperature to the required operating temperature. Driven by a circulation system, the high-temperature molten salt is transported to heat-consuming equipment, providing heat for high-temperature processes. After releasing heat, the molten salt temperature drops and returns to the boiler's heating surfaces for reheating, forming a circulating heating system.

The heat transfer medium of a molten salt boiler is typically a molten salt mixture composed of sodium nitrate, potassium nitrate, sodium nitrite, and other salts in a specific proportion. This type of molten salt mixture boasts excellent thermal stability, high thermal conductivity, and specific heat capacity. It remains liquid at high temperatures, is nonvolatile and nonflammable, and can stably transfer heat over a wide temperature range. Different salt ratios can adjust the molten salt's performance parameters, such as its melting point and operating temperature range, to suit diverse industrial needs.

The typical operating temperature range for molten salt boilers is 400°C-600°C. Some specially formulated molten salts and specially designed molten salt boilers can exceed 600°C, meeting the ultra-high-temperature heating requirements of the industrial sector and enabling complex production processes.

Excellent High-Temperature Stability: Molten salt mixtures resist decomposition and oxidation in high-temperature environments, maintaining stable physical and chemical properties over long periods of time. This ensures continuous and reliable boiler operation under high-temperature conditions, reducing equipment failures and maintenance costs caused by medium deterioration.

Long-Term Continuous Operation: Thanks to its excellent high-temperature stability and heat transfer performance, molten salt boilers can achieve long-term continuous operation, reducing equipment start-up and shutdown frequency and improving production efficiency. They are particularly suitable for industrial scenarios requiring high production continuity.

High System Complexity: Molten salt boilers have a relatively complex system structure. In addition to the boiler itself, they also require comprehensive auxiliary systems for molten salt heating, storage, transportation, insulation, and freeze protection. For example, to prevent the molten salt from solidifying at low temperatures, piping and equipment must be heated and insulated. During system downtime, the molten salt must be properly cooled and stored, which increases the complexity of system design, installation, and maintenance.

Due to their high-temperature heating capabilities and stable operating performance, molten salt boilers are primarily used in the following industries with special high-temperature requirements:

Solar Thermal Power Generation: In solar thermal power generation systems, molten salt serves as a heat storage and heat transfer medium, storing heat collected from the sun. This provides a stable heat source for the power generation system at night or on cloudy days, ensuring continuous and stable power generation.

Metallurgical Industry: Used in metal smelting, forging, heat treatment, and other processes, molten salt boilers provide a high-temperature environment for metal processing, improving the metal's mechanical properties and microstructure.

Chemical Synthesis Industry: In certain high-temperature chemical reactions, such as ammonia synthesis, methanol synthesis, and petroleum cracking, molten salt boilers provide the necessary high-temperature conditions, promoting smooth chemical reactions and increasing conversion rates and product yields.

Large-Scale Energy Storage Industry: In addition to its application in solar thermal power generation, molten salt can also be used in other large-scale energy storage systems, such as grid peaking and energy storage. This converts electricity during off-peak periods into stored heat, releasing the heat during peak hours for power generation or heating, achieving rational energy allocation and efficient utilization.

Thermal Oil

Thermal oil boilers use organic thermal oil as the heating medium. This medium has a low vapor pressure and stable heat transfer performance in the medium-to-high temperature range (≤350°C). However, during long-term high-temperature operation, organic thermal oil is prone to chemical reactions such as oxidation and cracking, which can degrade the medium's quality. Regular inspection and replacement are required, increasing maintenance costs. Furthermore, if a leak occurs, organic thermal oil can easily cause a fire when exposed to air and open flames, necessitating strict safety management requirements.

Molten Salt

Molten salt boilers use a molten salt mixture as the heating medium. It exhibits excellent thermal stability and is resistant to decomposition and oxidation in high-temperature environments (400°C-600°C). This results in a relatively long service life, reducing the frequency of medium replacement and maintenance costs. Furthermore, molten salt is non-flammable, so even if a leak occurs, it will not cause a fire, providing enhanced safety in high-temperature conditions. However, molten salt solidifies at low temperatures. Therefore, effective heating and insulation measures are required during system startup, shutdown, and operation to prevent solidification and clogging of pipelines. This places higher demands on system operation, management, and maintenance.

Thermal Oil Boiler: Medium-Temperature Operation (≤350°C)

The operating temperature of a thermal oil boiler is primarily limited by the thermal stability of organic thermal oil, with its typical maximum operating temperature typically not exceeding 350°C. While some special types of thermal oil and modified boilers can reach temperatures approaching 400°C, the medium's stability decreases significantly at this temperature, significantly increasing the safety risks of the equipment. Therefore, these are generally used only under specific and strictly controlled operating conditions.

Molten Salt Boiler: High-Temperature Operation (400°C-600°C)

The excellent high-temperature stability of the molten salt mixture enables molten salt boilers to operate stably in the 400°C-600°C range. For some specially designed boilers using high-performance molten salt, their operating temperatures can be further increased, meeting the ultra-high-temperature heating requirements of industrial applications, such as certain high-end chemical synthesis and specialized metal smelting processes.

When using the same fuel type, the overall thermal efficiency of thermal oil boilers and molten salt boilers is similar. This is because both utilize similar heat transfer principles: fuel combustion generates heat, which is then transferred to the heat transfer medium via a heating surface.

However, under high-temperature operating conditions, the thermal efficiency of molten salt boilers is slightly higher than that of thermal oil boilers. On the one hand, the relatively high thermal conductivity of molten salt enables more efficient heat transfer at high temperatures. On the other hand, the relatively low heat loss of molten salt at high temperatures reduces heat waste, resulting in molten salt boilers exhibiting superior thermal efficiency at high temperatures.

In terms of overall purchase cost, there is little difference between thermal oil boilers and molten salt boilers. However, when broken down, the purchase cost of thermal oil boilers is slightly lower than that of molten salt boilers.

Thermal oil boilers have a relatively simple structure and require fewer auxiliary systems. For example, they don't require complex heating and antifreeze systems, making them easier to manufacture and install. Therefore, their initial purchase costs are relatively low. Molten salt boilers, on the other hand, have a more complex system structure and require comprehensive auxiliary equipment for molten salt heating, storage, heating, and insulation. These equipment also place higher demands on materials and manufacturing processes, resulting in a relatively higher purchase cost.

Thermal Oil Boilers: Low Operating Costs

The operating costs of thermal oil boilers primarily include fuel consumption, thermal oil replacement, and equipment maintenance. Fuel consumption is relatively stable due to their medium temperature operation and relatively manageable heat loss. While thermal oil requires regular replacement, the replacement cycle is relatively long, and thermal oil is relatively affordable. Furthermore, their simple structure and easy maintenance contribute to low maintenance costs. Overall, thermal oil boilers have lower operating costs.

Molten Salt Boilers: High Operating Costs

The operating costs of molten salt boilers are relatively high, primarily due to the following factors. First, fuel consumption is relatively high due to the high operating temperature. Maintaining high operating temperatures requires a relatively high fuel consumption. Second, molten salt is relatively expensive, and while its service life is long, replacement costs are still considerable. Furthermore, molten salt boilers have complex auxiliary systems, such as the heat tracing system, which requires continuous energy consumption. Maintenance is also difficult and expensive, resulting in high operating costs. These factors contribute to the high operating costs of molten salt boilers.

Thermal Oil Boilers: Horizontal and Vertical

Thermal oil boilers offer a flexible design structure, with both horizontal and vertical configurations available. Horizontal thermal oil boilers offer advantages such as a large heating area, high thermal efficiency, and easy installation and operation. They are suitable for most industrial scenarios, especially those with high heating load requirements. Vertical thermal oil boilers, with their small footprint and compact structure, are suitable for companies with limited installation space and are widely used in small and medium-sized production facilities. Companies can select the appropriate thermal oil boiler structure based on their site conditions, heating requirements, and other factors.

Molten Salt Boilers: Primarily Vertical

Due to the characteristics of molten salt, molten salt boilers are primarily vertical. The vertical structure facilitates uniform heating and circulation of the molten salt, reducing the risk of localized overheating and solidification within the boiler. It also facilitates the installation of comprehensive heating and insulation systems to ensure the molten salt remains liquid throughout the system. While horizontal molten salt boilers are available in rare circumstances, they require more complex structures and control systems to account for the characteristics of molten salt, limiting their application range.

Thermal Oil Boilers

The operation of thermal oil boilers is relatively simple, and operators can master them with professional training. During startup, the thermal oil must be heated gradually to avoid rapid heating, which could lead to localized overheating and decomposition, potentially compromising medium quality and equipment safety. Typically, the thermal oil temperature is raised to operating temperature in stages according to a pre-set heating curve. This results in a relatively smooth startup process and a relatively short startup time. During normal operation, regular monitoring of thermal oil parameters such as temperature, pressure, and flow rate is sufficient to ensure stable equipment operation.

Molten Salt Boilers

Molten salt boilers are significantly more difficult to operate than thermal oil boilers. Before startup, the entire molten salt system, including the boiler, piping, and valves, must be preheated to ensure that all system components reach a temperature above the melting point of the molten salt. This prevents the molten salt from solidifying and clogging the piping after entering the system. This preheating process typically takes a long time and requires precise control of the preheating temperature and heating rate. During normal operation, parameters such as the molten salt temperature, level, and flow rate must be closely monitored. The operation of the heat tracing system must also be monitored to prevent molten salt from solidifying in the piping.

During shutdown, the handling of molten salt boilers is also unique. Heating and circulation cannot be stopped directly. The molten salt must first be slowly cooled to a certain temperature and then transferred to a dedicated molten salt storage tank for storage. Furthermore, the boiler and piping must be cleaned and maintained, and antifreeze measures must be implemented to prevent residual molten salt from solidifying and damaging the equipment. The entire shutdown process is complex and time-consuming, requiring a high level of operator skill and experience. 3.8 Safety

Thermal Oil Boilers

The primary safety hazard of thermal oil boilers is the risk of fire from leaks of organic thermal oil. Because organic thermal oil is flammable, leaks in components such as pipelines and valves during operation can cause fires if the oil comes into contact with air, open flames, or hot surfaces. Furthermore, if thermal oil is operated at high temperatures for extended periods without timely maintenance, it can crack and carbonize, forming carbon deposits that adhere to heated surfaces. This not only reduces thermal efficiency but can also cause equipment damage or even fires due to localized overheating. Therefore, thermal oil boilers require comprehensive safety features such as leak detection, fire prevention, and fire suppression, and regular safety inspections and maintenance must be strengthened.

Molten Salt Boilers

Molten salt is non-flammable. Therefore, even if it leaks during high-temperature operation, it will not cause a fire. From this perspective, molten salt boilers are safer than thermal oil boilers under high-temperature conditions.

However, molten salt boilers also present their own safety risks. On the one hand, there's the risk of solidification. If a system malfunction causes heating interruption or improper temperature control, the molten salt temperature drops below its melting point and solidifies. The solidified molten salt expands, potentially damaging the boiler, piping, valves, and other equipment, causing serious equipment failure. Cleaning the solidified molten salt is extremely difficult, leading to prolonged downtime. On the other hand, there's the risk of corrosion. Some molten salts can corrode equipment materials at high temperatures, especially in the presence of moisture, impurities, or oxygen. This corrosion rate accelerates, shortening the equipment's service life over the long term and even causing safety issues such as leaks. Therefore, molten salt boilers require the use of high-quality, corrosion-resistant materials, strict control of moisture and impurity levels within the system, and enhanced corrosion monitoring and maintenance.

Thermal Oil Boilers: General Industrial Medium-Temperature Heating

Thermal oil boilers are primarily suitable for general industrial applications requiring heating temperatures below 350°C, meeting the needs of most medium-temperature heating processes. In addition to the aforementioned textile, printing and dyeing, plastics, food, wood processing, and building materials industries, molten salt boilers are also widely used in rubber product processing (such as rubber vulcanization and drying), papermaking (pulp drying and paper shaping), and the pharmaceutical industry (drug concentration, drying, and sterilization), providing a stable and reliable medium-temperature heat source for these industries.

Molten Salt Boilers: High-Temperature Chemical Processes and Special Applications

Due to their exceptional high-temperature heating capabilities, molten salt boilers are primarily suitable for chemical processes requiring ultra-high temperatures and specialized applications. These include:

Chemical Industry: Suitable for the synthesis of high-temperature chemical products such as melamine, phthalic anhydride, and acrylic acid, as well as the production of alumina, urea, and caustic soda. These processes require a stable, ultra-high temperature environment to ensure the full performance of chemical reactions. Molten salt boilers can precisely meet these temperature requirements, improving product yield and purity. Furthermore, their high-temperature stability ensures continuous and uninterrupted production in processes such as cracking oil processing and refrigerant synthesis.

Metallurgical Industry: In addition to the metal smelting and forging mentioned above, molten salt boilers can also be used for high-temperature heat treatment of specialty alloys. For example, in the production of high-strength steel and titanium alloys, temperatures exceeding 500°C are required to adjust the metal's internal structure. Molten salt boilers can provide uniform and sustained high temperatures, helping the material achieve the desired mechanical properties.

In the new energy sector: In addition to solar thermal power generation, molten salt boilers can serve as auxiliary heat sources in high-temperature water electrolysis processes for hydrogen production, providing a stable high-temperature environment for the electrolysis unit and reducing electrolysis energy consumption. In the high-temperature gasification process of biomass energy, molten salt boilers can also provide the necessary heat for the gasifier, improving biomass conversion efficiency.

4. How to Choose the Right Boiler for Your Factory?

When a factory's production process requires heating temperatures ≤350°C, a thermal oil boiler is the preferred choice. In these scenarios, there's no need for ultra-high-temperature performance; the medium-temperature heating capacity of a thermal oil boiler fully meets the requirements and avoids the costly overhead of higher-spec equipment.

If a factory prioritizes streamlining operational processes and controlling operating costs, thermal oil boilers are also advantageous. Their relatively simple operation allows operators to quickly become operational after a short training period, reducing the cost of recruiting and training specialized technicians. Furthermore, their lower fuel consumption, maintenance costs, and thermal oil replacement costs significantly reduce the factory's long-term operational burden.

In terms of industry compatibility, thermal oil boilers are suitable for most processes in industries such as textiles, rubber, plastics, food, and building materials, including fabric shaping in textile printing and dyeing, rubber vulcanization, plastic injection molding, food baking and sterilization, and drying raw materials for building materials. Taking the food industry as an example, indirect heating using thermal oil avoids direct contact between the heat source and food, meeting food safety and hygiene requirements. Precise temperature control also ensures consistent food taste and quality.

When production processes require temperatures ≥400°C, molten salt boilers become essential. In these cases, the upper temperature limit of thermal oil boilers no longer meets the demand. Molten salt boilers, on the other hand, operate stably in the high-temperature range of 400°C-600°C (or even higher), supporting processes with stringent temperature requirements, such as high-end chemical synthesis and specialty metal smelting.

If continuous high-temperature operation is crucial for a factory, such as in the continuous production equipment of a large chemical company or the 24-hour energy supply system of a solar thermal power station, the long-term continuous operation capability of a molten salt boiler can reduce equipment start-up and shutdown cycles, avoiding production interruptions and financial losses caused by downtime. For example, in solar thermal power generation, molten salt not only transfers heat but also stores it, releasing it at night or on cloudy days to maintain power generation and ensure a continuous energy supply.

From an application perspective, molten salt boilers are more suitable for large-scale chemical production (such as melamine and phthalic anhydride synthesis), special alloy processing in the metallurgical industry, and renewable energy (solar thermal power generation and high-temperature hydrogen production). For example, in the heat treatment of special alloys in the metallurgical industry, the stable high temperature provided by molten salt boilers ensures sufficient internal microstructural transformation of the alloy, improving key properties such as strength and hardness, and meeting the stringent material requirements of high-end manufacturing.

When selecting a boiler, one should not only focus on the initial purchase price but also comprehensively evaluate the entire lifecycle cost, including purchase cost, fuel consumption, maintenance costs, safety costs, and hidden costs caused by system complexity.

In terms of purchase cost, although thermal oil boilers are slightly lower, the cost should be considered in light of process requirements: If the process requires high temperatures, even the higher purchase cost of a molten salt boiler is a necessary investment; if the process only requires moderate temperatures, choosing a thermal oil boiler can reduce initial expenditure. Fuel consumption costs should be analyzed in conjunction with local fuel prices and the energy consumption characteristics of the equipment. For example, in regions with lower natural gas prices, the fuel cost gap between the two types of boilers may narrow, but in the long run, medium-temperature operation of thermal oil boilers will still be more energy-efficient.

Regarding maintenance costs, thermal oil boilers require regular testing and replacement of the thermal oil quality, while molten salt boilers require heat tracing system maintenance and addressing potential molten salt solidification issues. The maintenance priorities for these two types differ, and a balance should be considered based on the plant's maintenance capabilities and budget. Safety costs should also not be ignored. Thermal oil boilers require investment in fire prevention and fire suppression equipment, while molten salt boilers require increased investment in corrosion-resistant materials and anti-solidification systems. These factors must also be factored into cost considerations.

Furthermore, system complexity carries hidden costs. For example, molten salt boilers require auxiliary equipment such as molten salt storage tanks and heat tracing piping, which increase site occupation and installation and commissioning costs. The simpler system of a thermal oil boiler can reduce these hidden expenses.

Due to the diverse production scale, process details, site conditions, and safety requirements of different plants, it's difficult to make an absolutely accurate selection based solely on general standards. Therefore, consulting with industry experts is crucial.

Through on-site research, experts can gain a detailed understanding of the plant's process temperature profile (e.g., whether there are temperature fluctuations or peak temperature requirements), production scale (e.g., the heating load of a single production line, and whether there are expansion plans), site constraints (e.g., floor space and floor height requirements for boiler structure), and safety and compliance standards (e.g., industry-specific safety regulations and environmental requirements). These experts can then develop a personalized boiler selection plan.

For example, a medium-sized chemical company plans to add a new phthalic anhydride production line. Initially, they determine that high-temperature heating is required, but are unsure of the specific temperature fluctuation range and load requirements. Experts can calculate the precise heating load and temperature control accuracy requirements based on the company's raw material supply and product output targets. They can also assess whether the site can accommodate the molten salt boiler's auxiliary systems. Ultimately, they can recommend whether to select a molten salt boiler and the specific model, avoiding blind selection that could lead to a mismatch between equipment and process.

Overall, thermal oil boilers and molten salt boilers each have their advantages, and the choice should be based on the factory's production needs. For medium-temperature heating (≤350°C) with a focus on ease of operation and cost control, thermal oil boilers are more suitable. For ultra-high-temperature heating (≥400°C) requiring continuous and stable operation, molten salt boilers are more suitable. The selection process should consider multiple factors, including lifecycle costs and process compatibility. Choosing the right boiler will maximize production and profitability.