Choosing the right Steam Boiler for your garment factory can be a game-changer. It significantly impacts production efficiency and cost control. However, with various boiler options available, a one-size-fits-all approach won't work. Here's a guide to ensure you select the ideal boiler for your specific needs:

1. Prioritizing Energy Efficiency:

- High Steam Consumption: Garment factories use steam extensively for washing, drying, and ironing. Energy efficiency is paramount when selecting a boiler.

- Electric vs. Gas-fired Boilers:

- Electric Boilers: Ideal if your factory has ample electricity capacity, enjoys low electricity rates, or has off-peak discounts.

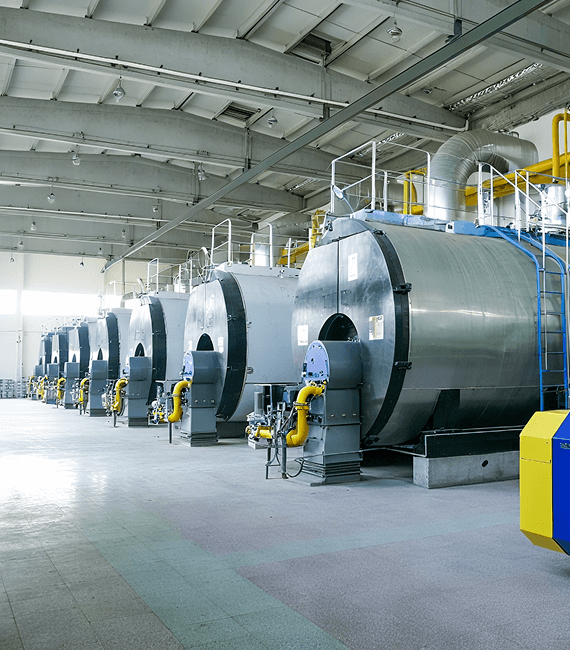

- Gas-fired Boilers: A more cost-effective option if electricity is expensive but you have access to natural gas pipelines.

2. Balancing Environmental Impact:

- Stricter Regulations: Government regulations for emission reduction and energy conservation are becoming stricter. These vary by region and impact boiler selection.

- First-tier Cities: Stringent nitrogen oxide emission requirements often favor Electric Boilers.

- Second and Third-tier Cities: Consider Gas or Oil-fired Boilers if electric boiler operating costs are a concern.

- Remote Areas: Environmental regulations may be less restrictive, allowing for more flexibility in boiler selection.

3. Matching Steam Requirements:

Different garment production processes have varying steam needs, including:

- Steam Cleanliness: The level of purity required for specific tasks can differ.

- Steam Dryness: Processes may demand steam with minimal moisture content.

- Steam Pressure and Temperature: Specific processes may have precise pressure and temperature requirements.

The Ideal Boiler for Your Factory:

By carefully analyzing your garment factory's unique characteristics and steam requirements, you can select a boiler that is:

- Cost-Effective: Leverages energy efficiency and aligns with your budget.

- Eco-Friendly: Meets local environmental regulations and minimizes your environmental footprint.

- Production-Oriented: Perfectly suited to the specific steam needs of your garment production processes.

Remember: A thorough analysis of your specific needs is crucial to ensure you select the optimal steam boiler for your garment factory and achieve maximized production efficiency while minimizing costs.