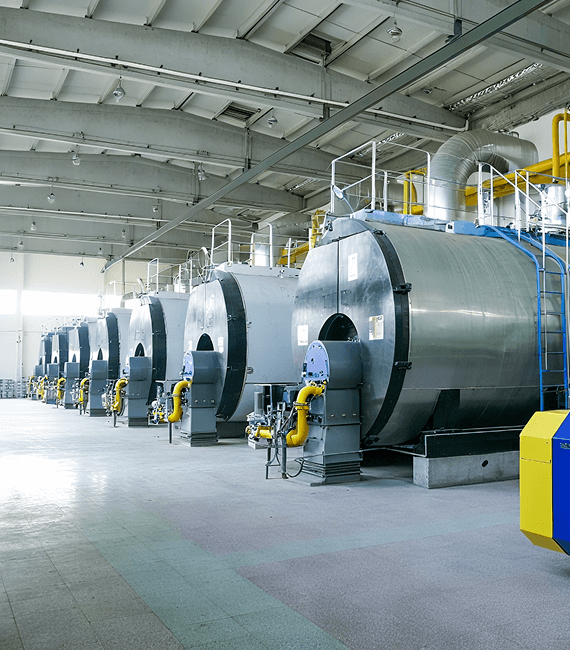

Biomass fuel boiler is a kind of boiler that uses biomass fuel as fuel. Compared with coal-fired boilers, it has the advantages of environmental protection and cleanliness. However, biomass fuel is slightly more expensive than coal, about 891 tons. Compared with electricity, gas, gasoline and diesel, it can save 40%-60%. The fuel of the coal-fired boiler design scheme is coal. The biomass fuel boiler design scheme can use biomass fuel as fuel. Because the calorific value of biomass fuel is much smaller than that of coal in the enterprise volume and the combustion sludge is large. Its design scheme includes furnace capacity, total combustion area, heating surface layout, total smoke flow,

The feeding system software and dust collector equipment are very different from coal-fired boilers. When using natural gas boilers, there are some technical standards for manufacturers and their actual operating staff, and in the case of application, there are some safety risks. Therefore, enterprises should not only specify technicalities for professional technicians, but also have some advantages:

(1 ) Large-diameter corrugated furnace: The boiler combustion chamber is composed of a large-diameter full-wave corrugated furnace. The combustion chamber has a large space, which can make the raw materials burn evenly when heated, and can reasonably digest and absorb thermal deformation. The radiation source has a large heating surface.

(2) High steam quality: the diameter of the pot shell is large, the water volume is large, and the adaptability to load changes is strong, and the humidity of the steam environment is in the controllable range.

(3) Safety Rainfall time is in the scope of controllability: the bottom layout of the combustion chamber of the boiler, the water level line clearly conforms to the technical specifications of my country, and the specified water level line specification is strictly followed to ensure the safety of the boiler operation.

(4) Multi-purpose safety explosion-proof equipment: An explosion-proof equipment connected to the furnace is set up on the control panel at the rear of the boiler to avoid the high-efficiency energy released in a moment when the fuel is strongly deflagrated in the furnace, and can be automatically calibrated.

(5) Convenient maintenance in the boiler: Hand holes are set on the top of the boiler, and special hand hole equipment is set up in the middle and lower parts of the front, rear, left and right ends of the boiler, which is conducive to the maintenance and cleaning of the equipment in the boiler and the bottom of the boiler.