Pharmaceutical boilers refer to boiler equipment used in the pharmaceutical industry.Pharmaceutical boilers are mainly used for heat energy supply in the pharmaceutical process,such as steam supply,hot water supply,etc.In the pharmaceutical process,high-temperature and high-pressure steam is often used for sterilizatio,drying and other processes,so the safety and stability requirements of pharmaceutical industry boilers are higher.Boilers for the pharmaceutical industry typically need to meet the following:

1.Temperature control:The pharmaceutical process requires precise temperature control,so the boiler needs to have good temperature regulation capabilities and be able to stably provide the required heat energy.

2. Efficient energy utilization:The pharmaceutical industry has high energy consumption requirements, and boilers need to have the characteristics of efficient energy utilization to reduce energy waste and costs.

3. Cleanliness and hygiene:The pharmaceutical industry has strict hygiene requirements for products, and boilers need to be clean and hygienic to prevent contamination and cross-infection.

4. Safety performance:The pharmaceutical process may involve some dangerous substances and high-temperature and high-pressure operations. The boiler needs to have safety performance, such as overheating protection, pressure protection, etc., to ensure the safety of operators and equipment.

5. Comply with relevant regulations and standards:The pharmaceutical industry has a series of regulations and standards, such as GMP (Good Manufacturing Practice), etc. Boilers need to comply with these regulations to ensure the compliance and quality of the production process.

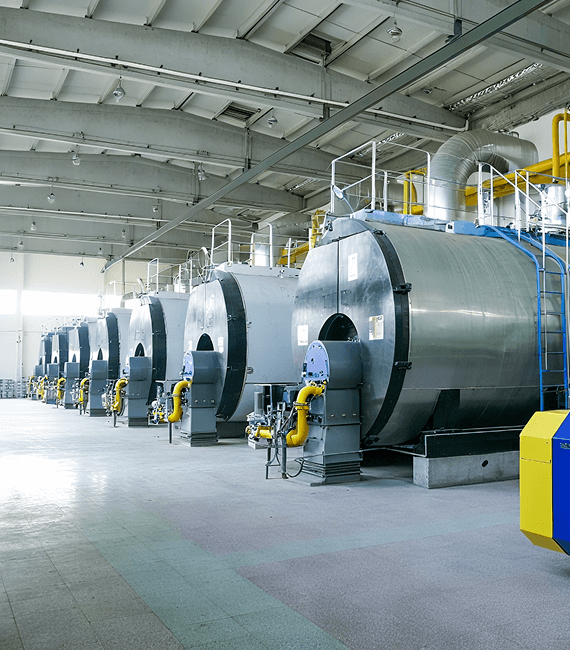

According to the specific pharmaceutical process and needs, pharmaceutical industry boilers can use different fuels and combustion methods to meet the heat energy needs in the pharmaceutical process, such as steam boilers, hot water boilers, thermal oil boilers or electric boilers. At the same time, the selection and design of boilers need to be reasonably selected and customized based on process requirements and environmental conditions. The types of boilers commonly used in the pharmaceutical industry are as follows:

1. Steam boiler:Steam boiler is one of the most commonly used types of boilers in the pharmaceutical industry. They generate high-pressure steam, which is used for example in heating reactors, drying equipment and sterilization processes.

2. Hot water boiler:Hot water boiler is usually used for some specific applications in the pharmaceutical industry, such as heating, air conditioning and cleaning equipment. They provide hot water at high temperatures but do not produce steam.

3. Thermal oil boiler:Thermal oil boiler uses hot oil as the heat transfer medium, heats the hot oil to high temperature, and then transfers the heat energy to the equipment in the pharmaceutical process through the heat exchanger. Thermal oil boilers are often used in pharmaceutical processes that require high-temperature heating.

4. Electric boiler:Electric boiler uses electric energy as energy source to heat water into steam or hot water through electric heating. Electric boiler is widely used in some pharmaceutical factories, especially in areas where there is no other energy supply.

In summary, it is important for boilers in the pharmaceutical industry to meet strict regulatory requirements and adhere to Good Manufacturing Practices (GMP) to ensure the safety and quality of the production process. At the same time, pharmaceutical industry boilers also require regular maintenance and upkeep to extend the service life of the equipment and ensure its normal, safe and efficient operation.