Reboilers (Kettle type boilers) are heat exchangers typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. The heat supplied to the column by the reboiler at the bottom of the column is removed by the condenser at the top of the column.

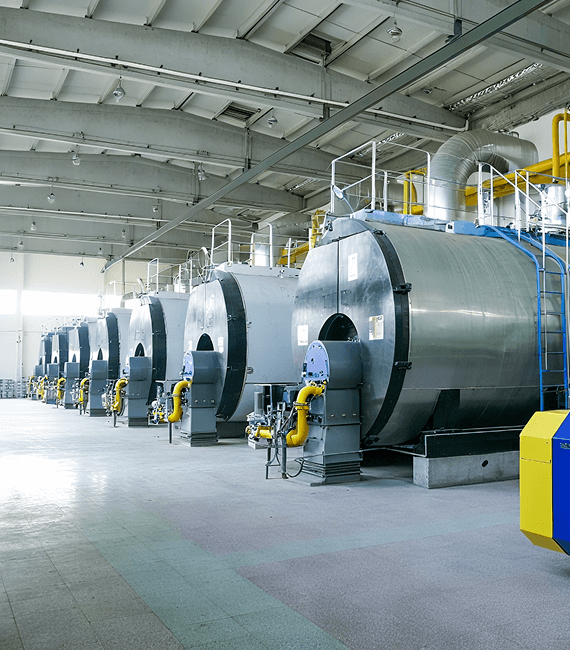

Water tube boilers have larger capacity and higher pressure than fire tube ones. Large steam users are better suited for the water tube boiler. The industrial water tube boilers are typically used for producing steam or hot water for large industrial process applications, like the textile industry, paper plant, steel and iron plant, chemical industry, utility, thermal power plant, etc.

The main production units of refineries usually include: crude oil distillation (normal, vacuum distillation), thermal cracking, catalytic cracking, hydrocracking, petroleum coking, catalytic reforming, refinery gas processing, petroleum product refining, etc. Steam boilers and heat transfer oil boilers are important equipment often used in the production of light oil refining industry. They are an indispensable source of heat and power in the production process of refineries. They are not only used in petrochemical production processes, but also in heating oil and increasing fluidity. Generally, heat is supplied in the steps of vacuum distillation, vacuum distillation, and coking deep processing of crude oil in refined oil refining.